User manual – Nilfisk-ALTO SR1800C B-D User Manual

Page 67

USER MANUAL

33014817(2)2006-06 A

17

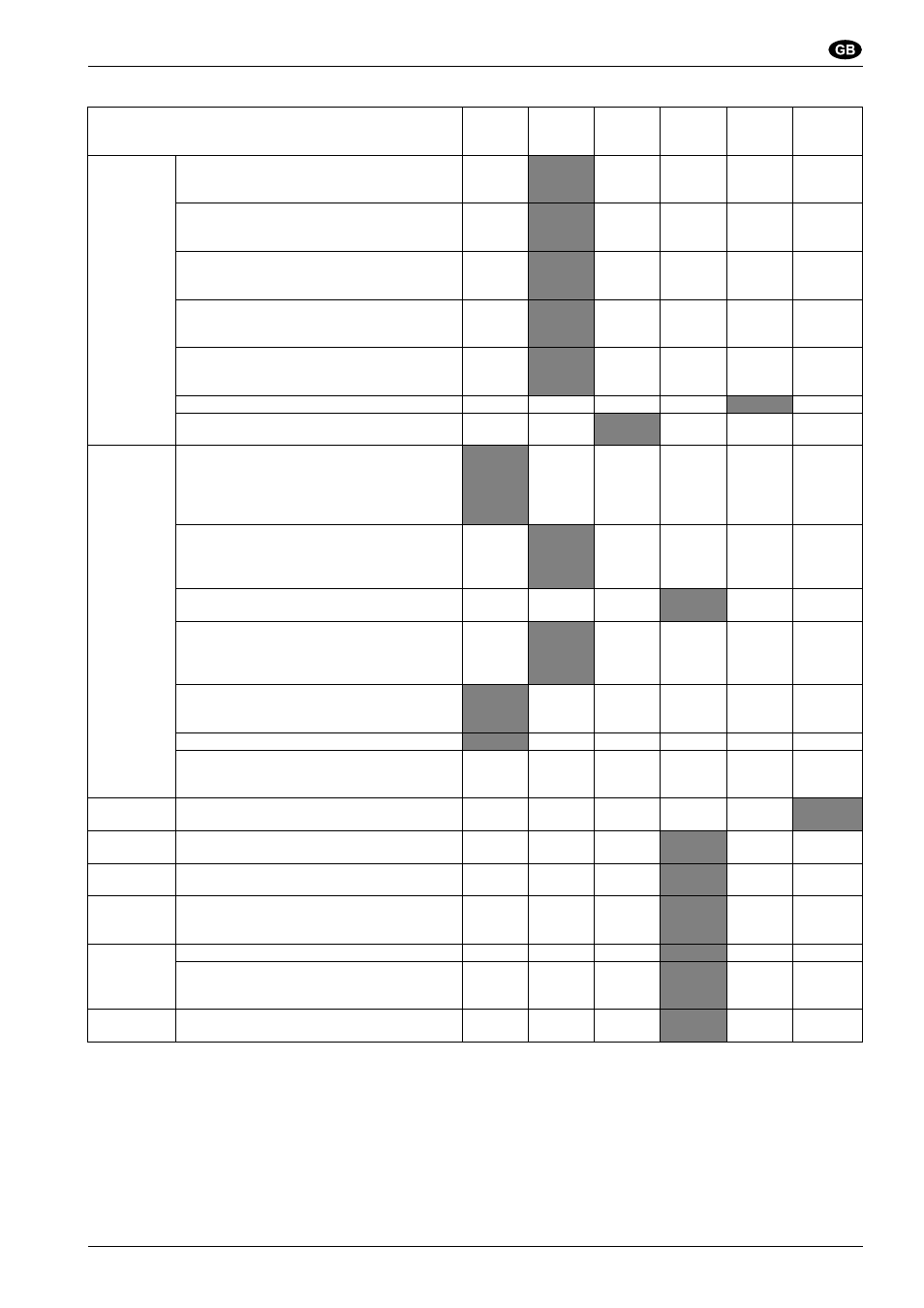

Drive direct current motor (SR 1800C B)

Maintenance

Every 150

hours

Every 200

hours

Every 400

hours

Every 6

months

Every

year

Every time

a check is

carried out

Commutator

Ensure that the surface along which the carbon

brushes slide is covered with an even, shiny,

transparent light grey film.

Check that there are no black marks or burns

between the commutator segments and on the

commutator outer crown

Ensure that the commutator surface is not lined,

deeply grooved or burnt on the segment in or out

edges.

Check that the brooms have not grooved the

commutator surface and that the insulating mica

does not protrude from the copper segment.

Check that the commutator is clean and that there

are no burns on the segments; if necessary, clean

the commutator as described.

Check eccentricity.

Clean the commutator with special rubber sticks. If

necessary, clean between the segments.

Carbon

brushes

Check the carbon brush for wear. It is worn out

when more than half of its total length has been

consumed. Check that it slides freely in the brush

holder, that it is pressed correctly by the spring and

that the spring is still elastic.

Ensure that the surface along which the carbon

brushes slide is evenly and highly polished and

that any lines or porosity are extremely small and

of similar dimensions.

Check the wire for wear and ensure that the

connection terminals are well tightened.

Ensure that there are no big lines, deep grooves,

craters, burns or splinters on the carbon brush

edge and that all the carbon brushes are worn in

the same way.

Check the housing for wear and clearance.

Brushes usually last from 6 months to 1 year,

depending on use.

Check the carbon brush and coupling pressure.

When the warning light turns on, the carbon

brushes need to be replaced, even if 300 hours

have not been reached.

Terminals

Check that supply bolt nuts are well tightened and

that the insulating materials are in good condition.

Fan

Ensure that air intakes are not clogged and that the

fan turns freely.

Bearings

Check the temperature and the vibration and noise

degree.

Insulation

Use a megger, especially when the environment is

wet, to check the insulation value: it should never

be less than 2 MOhm.

Screws

Check that the screws are not loose.

Check that there are no faulty contacts in the

electrical connections which could lead to local

overheating.

Windings

General cleaning. Check that the insulation to

ground is less than 2 MOhm.