Problems and remedies, User manual – Nilfisk-ALTO SR1800C B-D User Manual

Page 62

USER MANUAL

12

33014817(2)2006-06 A

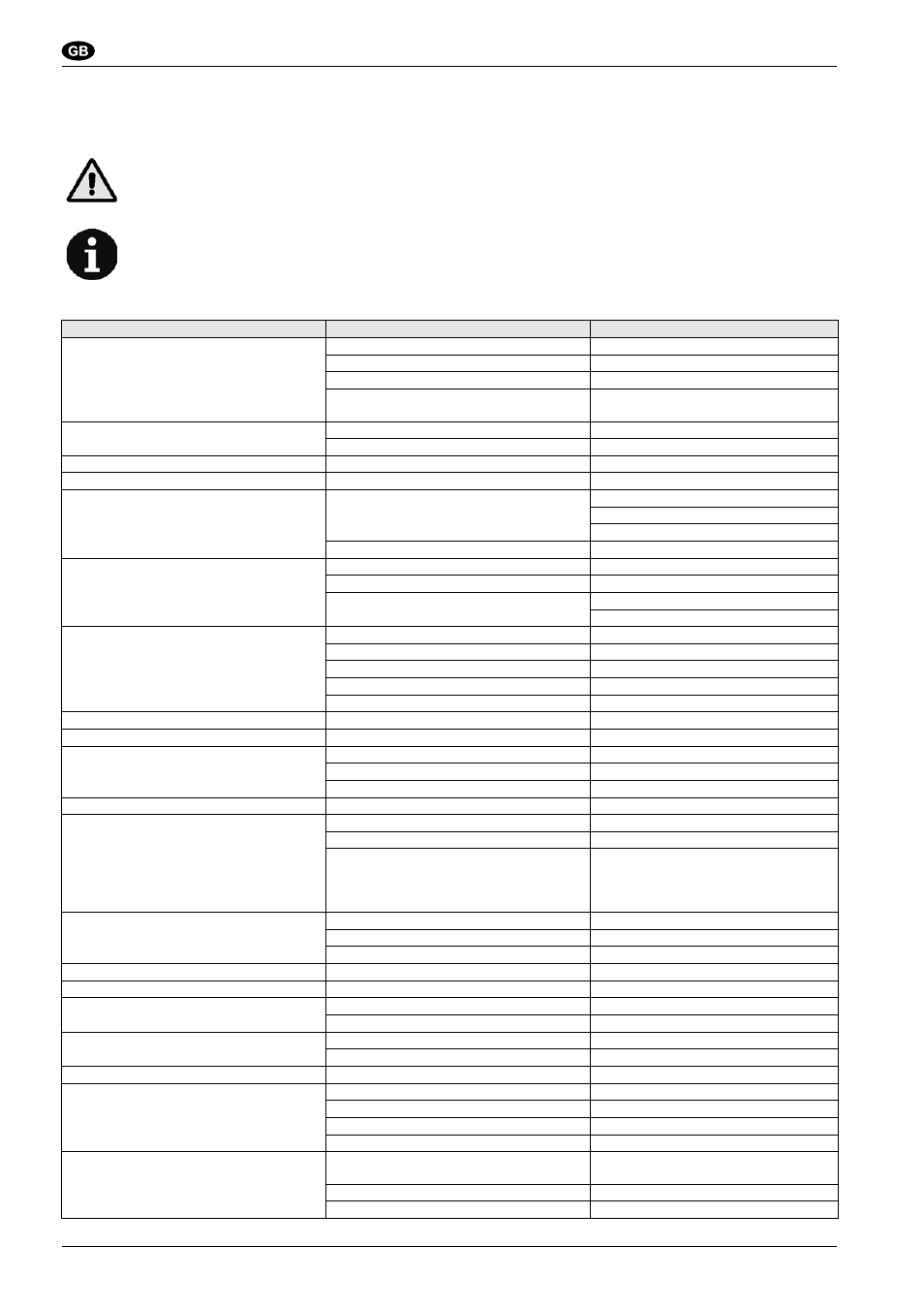

PROBLEMS AND REMEDIES

The following table shows the most frequent problems that may arise during the use, the possible causes and the suggested

remedies to solve them.

PROBLEMS AND REMEDIES

WARNING!

When applying a recommended solution, always follow the instructions relating to it.

NOTE

Do not hesitate to contact Nilfisk-Advance if a problem cannot be solved by following the instructions

provided.

PROBLEM

CAUSE

REMEDY

Heavy material not collected/traces of dirt left

behind during use

Excessive drive speed

Decrease drive speed

Light print

Adjust trace

Worn out broom

Replace brooms

Broom bristles bent or tangled with steel wire,

ropes etc.

Remove any tangled material

Excessive amount of dust left on the ground or

coming out of skirts

Fan off

Switch on the fan

Clogged filters

Clean filters

Material is thrown forward

Broken skirt gasket

Replace

Engine fails to start

See Troubleshooting in the engine Manual

Machine power is reduced

Insufficient pump oil feed

Check by-pass screw tightening

Check pump pressure (16 to 20 Bar)

Overhaul motor

Worn motors

Overhaul pump

The machine fails to run

Open by-pass

Check by-pass screw tightening

Faulty pedal control

Check pressure/replace pedal

No power to pump or motors

Overhaul motor

Overhaul pump

Machine fails to brake

No brake fluid

Top up fluid tank

Brake fluid pump failure

Overhaul pump

Air inside the system

Bleed system

Jaw cylinders failure

Replace cylinders

Worn or greasy brake lining

Replace brake lining

Steering unit hard to control

Locked power steering

Replace power steering

Model with hydraulic steering

Priority valve failure

Overhaul/replace priority valve

Hopper fails to lift/lower

Locked distributor

Check distributor

Locked solenoid valve

Check voltage, check operation

Worn cylinder gaskets

Replace gaskets

Waste loss from hopper

Broken hopper gasket

Replace

Filter shaker fails to operate

Broken push-button

Replace

Blown fuse

Replace

Excessive motor absorption causes:

–

Worn carbon brushes

–

Dirty or worn bearings

–

Burnt armature or winding

Replace

Replace

Replace

Blown filter shaker fuse

Excessive motor absorption

(see above)

Faulty fuse

Replace

Shorted cables

Check system

Noisy fan

Hydraulic motor failure

Overhaul motor

Fan fails to operate

No pressure to pump

Check pump pressure

Hydraulic model

Locked distributor

Check distributor

Motor failure

Overhaul motor

Skirt fails to open

No pressure to cylinder

Check cylinder

Locked linkage

Check linkage

Skirt gasket lifted by broom

Skirt gasket too long

Shorten/replace

Poor suction

Clogged pipe

Clean pipe

Poor pressure to fan motor

Check pressure

Motor failure

Overhaul motor

Clogged or broken closed pocket filter

Clean/replace filter

Brooms fail to turn

No pressure to motors

Check gear pump pressure (replace gear

pump)

Locked distributor

Check/replace motor

Check distributor