Troubleshooting – Brother LX2500 User Manual

Page 41

40

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

6

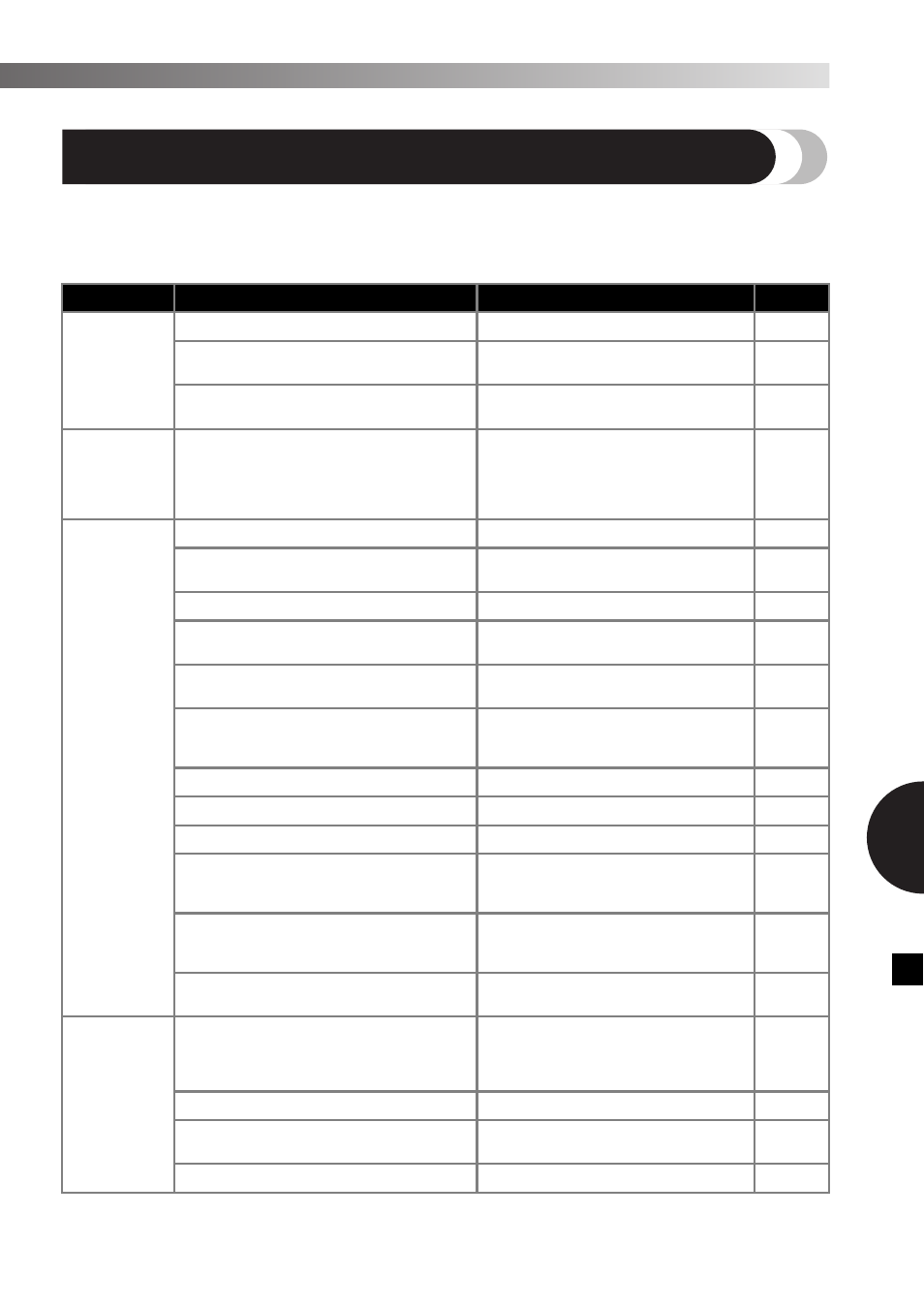

TROUBLESHOOTING

If the machine stops operating correctly, check the following possible problems before requesting service. You can

solve most problems by yourself. If you need additional help, the Brother Solutions Center offers the latest FAQs and

troubleshooting tips. Visit us at “ http://solutions.brother.com ”. If the problem persists, contact your dealer or the

nearest authorized service center.

Symptom

Possible cause

How to put it right

Page

The sewing

machine does

not work.

The main power switch is turned off.

Turn on the main power switch.

7

The bobbin-winder shaft is pushed to the

right.

Move the bobbin-winder shaft to the

left.

12

You have not used the foot controller

properly.

Use the foot controller properly.

7

Fabric being

sewn with the

machine

cannot be

removed.

Thread is tangled below the needle plate.

Lift up the fabric and cut the threads

below it, and clean the race.

38

The needle

breaks.

The needle is incorrectly installed.

Correctly install the needle.

7

The needle clamp screw is loose.

Use the oval screwdriver to firmly

tighten the screw.

8

The needle is bent or blunt.

Replace the needle.

7

The upper thread was not threaded

correctly.

Correct the upper threading.

14

You have not used the right combination of

fabric, thread and needle.

Choose a thread and needle that are

appropriate for the type of fabric.

17

The presser foot you are using is not

appropriate for the type of stitch that you

want to sew.

Attach the presser foot that is correct

for the type of stitch that you want to

sew.

–

The upper thread tension is too tight.

Loosen the upper thread tension.

22

You are pulling the fabric too much.

Lightly guide the fabric.

–

You have not fitted the spool properly.

Fit the spool properly.

15, 20

The area around the hole in the needle

plate or the presser foot is scratched.

Replace the needle plate.

Contact your retailer or the nearest

authorized service center.

–

The bobbin case is scratched.

Replace the bobbin case.

Contact your retailer or the nearest

authorized service center.

–

You have not used a bobbin that has been

designed for this machine.

Use a bobbin that has been designed

for this machine.

11

The upper

thread

breaks.

You have not threaded the upper thread

properly. (For example, you have not fitted

the spool properly, or the thread has come

out of the guide above the needle.)

Correct the upper threading.

14

There are knots or tangles in the thread.

Remove any knots or tangles.

–

The needle is not appropriate for the thread

you are using.

Choose a needle that is appropriate for

the type of stitch.

17

▼ The upper thread tension is too tight.

Loosen the upper thread tension.

22