Uick, Tart, Uide – UEi Test Instruments C157OILKIT User Manual

Page 7: Co r, Aux s

Q

uick

S

tart

G

uide

.

7

Rotate test selector to Exch

Test. Call for heat on the

system. Observe and wait

for O2 readings to stabilize.

Prior to the blower turning

on, and after readings have

stabilized, press the SEND

button. This will store the

Pre-Blower test segment.

After the blower turns on

press PUMP to start the Post-

Blower test.

The meter will wait 30 sec-

onds and then record the

Post-Blower values for CO, O2

and Excess Air. Test results

will automatically be stored

to exchange reports. Report

includes both Pre and Post

Blower test segments.

To view test results rotate test

selector to “MENU” go to the

“REPORT” screen and select

EXCH. Select “VIEW” and

scroll to desired log. Press

“SEND” to print.

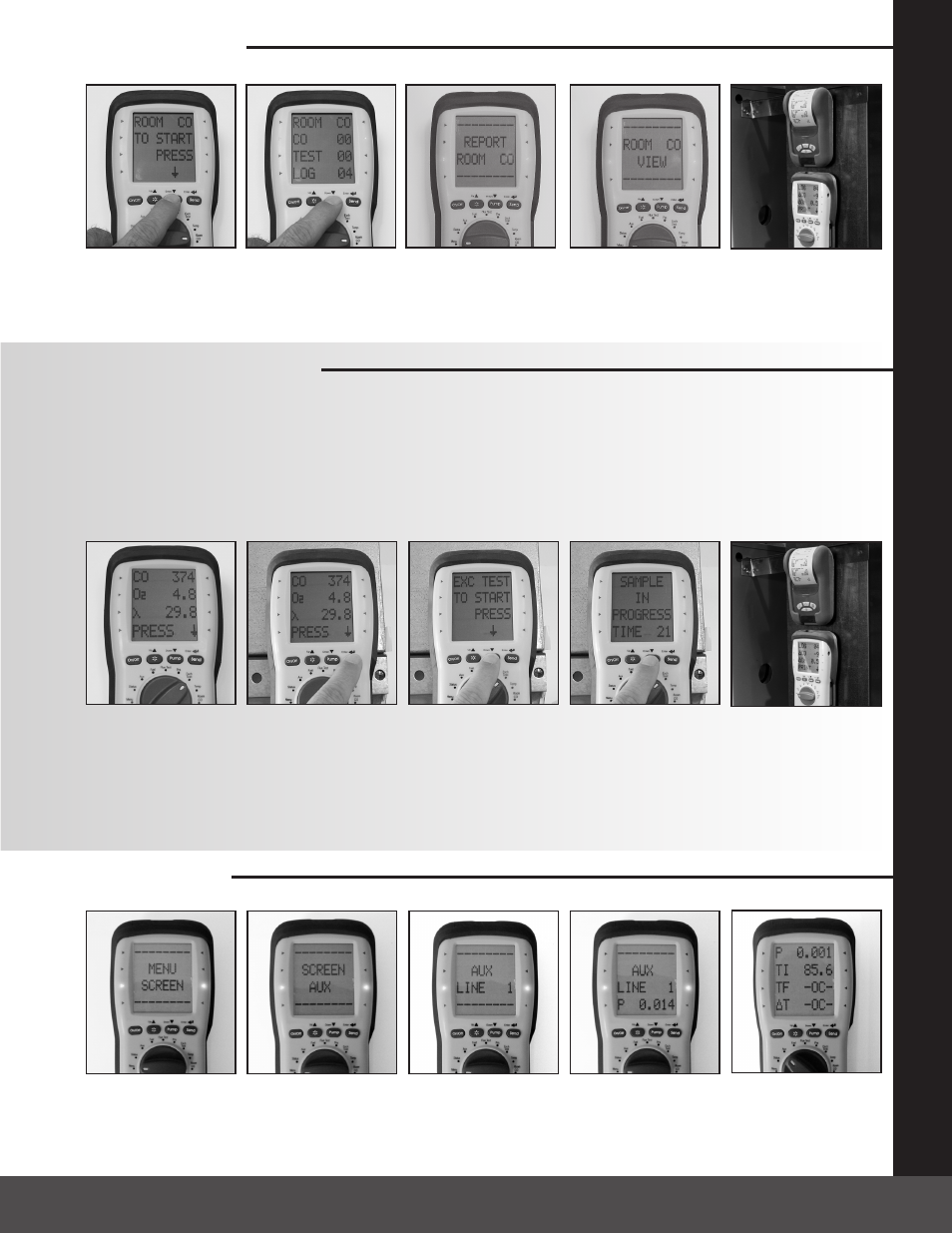

Rotate test selector to

“MENU”

scroll

“s“UP or

“t“DOWN to SCREEN.

Press “SEND”.

Scroll

“s“UP or “t“DOWN

to select the LINE you wish to

change. Press “SEND”.

(LINE 1 shown)

Scroll

“s“UP or “t“DOWN

to select the function you

wish to display. Press

“SEND”. (Pressure shown)

Rotate selector to “AUX”

to view. Pressure is now

shown in line 1 along with

T1, T2 and Differential/

delta T.

Scroll

“s“UP or “t“DOWN

to AUX. Press “SEND”.

h

EAt

E

XChAnGEr

t

Est

There are many methods to test heat exchanger integrity. One of these is to observe the Excess Air, O2 and CO readings both before and after the

blower turns on. If the heat exchanger is sealed your O2 and CO readings should remain fairly stable. A breach in the heat exchanger may allow fresh air to

be forced into the flue after the blower turns on due to a pressure increase in the plenum. The result may be a rise in the measured O2 in the stack gas and an

increase in the Excess Air . In some sealed systems the fresh air drawn in through the breach may reduce the combustion air available leading to an increase in

the CO reading. If either of these situations are present it is probable that there is a problem with the Heat Exchanger which may require additional testing and

inspection .

NOTE: Many cracks are invisible to borescopes or the naked eye, and only open or separate from pressure or temperature changes during operations.

No probes or hose connec-

tions required for this test.

Place handset in the area to

be tested. Rotate test selector

to Room CO

Press the PUMP button to start

the test. CO readings will be

logged every 2 minute for a 30

minute time span

To view results rotate test

selector to “MENU” and

select “REPORT” Scroll to

“ROOM CO” and press

“SEND”.

Press “SEND” to VIEW

results.

CO r

OOm

t

Est

AUX s

EttinG

Press “SEND” again to print.

Great for checking for ambient CO and back drafting situations.

Programmable Auxiliary screen allows for Tech selectable test parameters to be chosen.