Trimec ES8000 V-Lock User Manual

Es8000 v-lock, Warning, Installation instructions

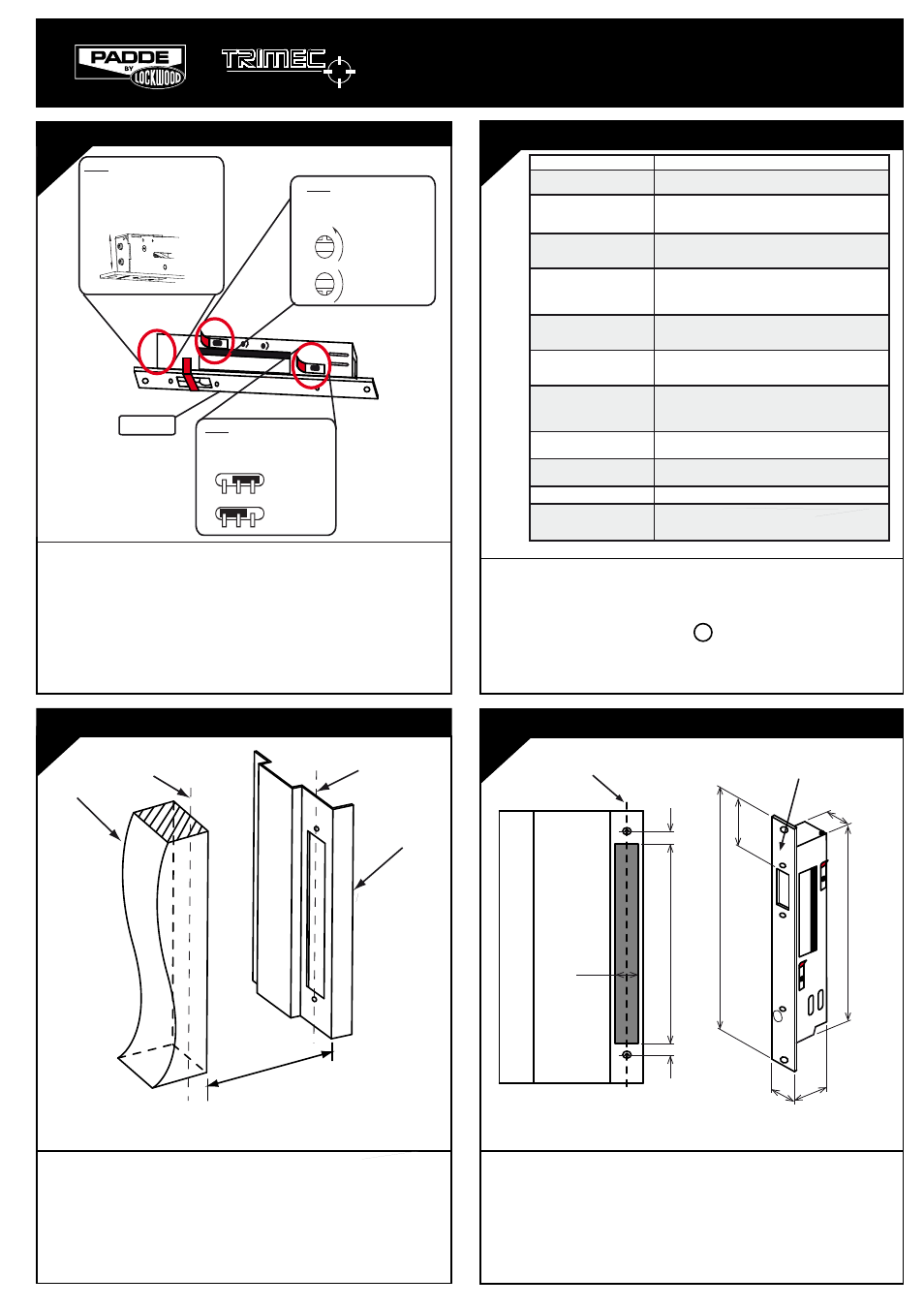

DOOR JAMB PREPARATION

42

30

M

Lock

Faceplate

256

15

15

30

256

50

24

210

Door Jamb

Line 2

ES8000 V-LOCK

WITH 30MM FACEPLATE

INSTALLATION INSTRUCTIONS

SELECTING THE MODE CONFIGURATION

STEP 1

- Loosen both screws on side of lock

body.

- With some force, slide screws in direction

required until stop at end of slot is reached.

- Hold in position and re-tighten screws.

PTL

PTO

STEP 3

- Change jumper position on Printed

Circuit Board beneath the red

re-sealable sticker as shown below:

Power-to-Open

(Fail Secure)

Power-to-Lock

(Fail Safe)

STEP 2

- Rotate Latch Plate screw beneath

the red re-sealable sticker according to

orientation shown below:

Turn counter-clockwise

180

o

for Power-to-Open

(Fail Secure)

Turn clockwise 180

o

for

Power-to-Lock (Fail Safe)

WARNING!

•

Lock mode configuration set to Power To Lock (Fail Safe). Ensure the correct

mode is set before applying power: you may be charged for incorrect

installation.

• Discard Bolt Label once correct mode is selected.

• If the lock had been installed or previously operated, the latch plate

screw (STEP 2) will not be visible. To change lock mode configuration,

contact your distributor for additional information.

• Ensure all re-sealable stickers and screws are re-attached after configuration

to prevent ingress of dust.

• V-Lock must ONLY be used in weather protected areas.

• V-Lock can ONLY be installed vertically or horizontally ABOVE the door

(not on or under the floor).

• V-Lock WILL NOT operate without strike plate. Strike plate MUST be

correctly aligned and in front of the M logo on the faceplate.

DOOR PREPARATION FOR STRIKE AND JAMB

2

1

Door

Door Jamb

Maximum door gap 8mm

• Before starting with the installation make sure the gap between the

door and the door jamb does not exceed 8mm

• Mark Line 1 corresponding to mid-plane of Door

• Mark Line 2 corresponding with Line 1 on the Door Jamb

Note: Make sure the Line 1 and Line 2 are aligned when the door is in

the closed position.

3

•

Mark cutout of V-Lock symmetrically about Line 2.

• Cutout size for faceplate must be 256mm x 30mm

• Prepare door jamb appropriately as shown.

Note: Thickness of faceplate - 3mm

Line 2

Line 1

Parameter

Specification

Door Gap

Ideally 3mm to 8mm only. 8mm maximum.

Lock Monitor Output

Voltage free changeover switch contacts rated for

48VDC / 100mA

Holding Force

AS4145.2 - 1993: Passed S3 (611kg for 1 minute)

Capable of 1000kg if strike plate is fully supported

Release under Side Load

15kg max at bolt with motorised unlocking (3 wire control)

3kg max at bolt with Power-To-Lock (Fail Safe) unlocking

and 2 wire control

Bolt Dimensions

Diameter = 11mm

Projection = 20.5mm

Power Supply (12-24VDC)

Regulation better than +/- 2%

1Amp Power supply required

Current Draw

Power to Lock holding current 130mA

Power to Open holding current 30mA

Initial locking and unlocking current draw higher

Misalignment tolerance

+/- 3.5mm

Operating Temperature

-10oC to +50oC at 90% RH

Durability

> 300,000 cycles

Certifications

SPECIFICATIONS AND NOTES

DRAWINGS NOT NOT TO SCALE. INFORMATION IN THIS DATASHEET MAY BE CHANGED WITHOUT NOTICE.

DRAWINGS NOT NOT TO SCALE. INFORMATION IN THIS DATASHEET MAY BE CHANGED WITHOUT NOTICE.

Bolt Label

•Up to 2-hour fire rating depending on doorset used, in accordance with

AS1905.1 - 1997, Part 1: Fire Resistant Doors

•CE compliant

•SCEC endorsed (high security strike bracket required)