Trimec ES110 Series Electric Strike User Manual

Installation instructions, Spare parts & accessories

IMPORTANT NOTE: Ensure any rebate strips or door stops are fi tted before proceeding.

For double-leaf doors, the inactive leaf must be securely fi xed in the closed position and a rebate strip fi tted to prevent

door over-travel.

100 Series strike suitable for 15mm latches, based on a 3mm door gap.

110 Series strike suitable for 18mm latches, based on a 3mm door gap.

INSTALLATION INSTRUCTIONS

100A/110A SERIES ELECTRIC STRIKE

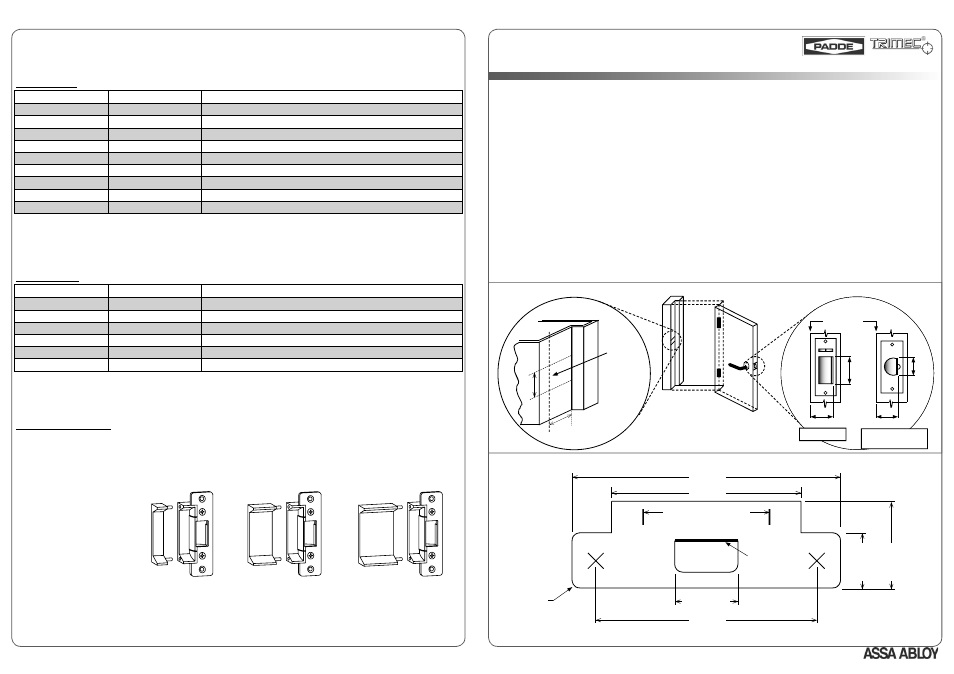

Mark positions X and Y of door latchbolt on door jamb (see Fig. 1).

Remove the backing of supplied stick-on template, and apply to door jamb. Ensure the lines “Front face of Lock Latch” on both template

and door jamb are aligned (see Note 1).

Scribe the door jamb according to template outline (see Fig. 2).

Prepare door jamb as per appropriate installation type; for Metal Jamb refer to Fig. 3, for Wood Jamb refer to Fig. 4. Install mounting tabs

where applicable. (see Note 2).

Ensure all wiring is correctly connected and not rubbing on sharp edges or interfering with any strike mechanism.

Install the strike temporarily in position and check there is no interference between the door, strike and lock face plates, and the extension

lip of strike during door closing. Ensure the deadlatching auxiliary bolt does not enter the strike keeper area when door is closed.

Check there is no pressure on the strike keeper when door is closed.

When all above checks are complete, secure strike with appropriate screws and re-check operation.

NOTE 1 : A 1mm clearance has been designed into the template to prevent the door exerting pressure on the strike when closed.

NOTE 2 : Allow suffi cient space between the electric strike unit and jamb cut-out for the wires. Bunching of wires may cause the unit

to malfunction.

1.

2.

3.

4.

5.

6.

7.

8.

Fig. 1 - Door Frame Preparation

Page 1

DRAWINGS NOT TO SCALE. INFORMATION IN THIS DATASHEET MAY BE CHANGED WITHOUT NOTICE.

Page 4

100A/110A SERIES

SPARE PARTS & ACCESSORIES

The following are available as optional extras:

SPARE PARTS

* When the use of extension lips is required, the standard model numbers of electric strikes must be suffi xed with “X” to denote

pre-drilled extension holes (e.g. 110X).

Align with

“Front Face

of Lock

Latch” line

on Template

y

x

y

X

X

y

or

Bevelled Face

x

x

y

y

Door Edge

or

Mortice Lock

Tubular/Cylindrical

Latch

Part Number

Qty Per Pack

Description

220100-501

1

12 V Solenoid Coil

220100-512

1

12 V Weather Resistant Solenoid Coil

220100-502

1

24 V Weather Coil

220100-511

1

24 V Weather Resistant Solenoid Coil

220100-509

1

48 V Solenoid Coil

200100-100

5

100 Series Locking Pins, Spring and Stop Screw

200100-110

5

100 Series Weather Resistant Locking Pins, Spring and Stop Screw

200110-100

5

110 Series Locking Pins, Spring and Stop Screw

200110-110

5

110 Series Weather Resistant Locking Pins, Spring and Stop Screw

ACCESSORIES

Part Number

Qty Per Pack

Description

220100-506

1

100 Series 15mm Extension Lip *

220110-502

1

110 Series 15mm Extension Lip *

220100-507

1

100 Series 25mm Extension Lip *

220110-503

1

110 Series 25mm Extension Lip *

220100-508

1

100 Series 50mm Extension Lip *

220100-504

1

110 Series 50mm Extension Lip *

An ASSA ABLOY Group brand

DA0006, Issue 8: 16th Feb 2007

104.8mm

Limits of Extension Lips

59.5mm

*86mm

*123.7mm

Keeper Width

38.8mm

31.7mm

*43.7mm

NOT TO SCALE

Front Face of

Lock Latch

R 4.0mm

15mm extension lip (A),

25mm extension lip (B)

50mm extension lip (C)

available as optional extras.

C

50mm

A

15mm

B

25mm

STRIKE FACE PLATES

Fig. 2 - 100A/110A Series ANSI Face Plate Type “A” Template Outline

For a wide range of strike face plates to suit a particular application, please contact your nearest distributor.

*These dimensions have a tolerance of +0.8mm/-0

Template outline may vary depending on strike face plate used.