Installation, Warning, Electrical shock hazard – ProMariner Combi Inverter Charger User Manual

Page 15

I n s t a l l a t i o n G u i d e l i n e s

26

25

Installation

I n s t a l l a t i o n G u i d e l i n e s

Installation

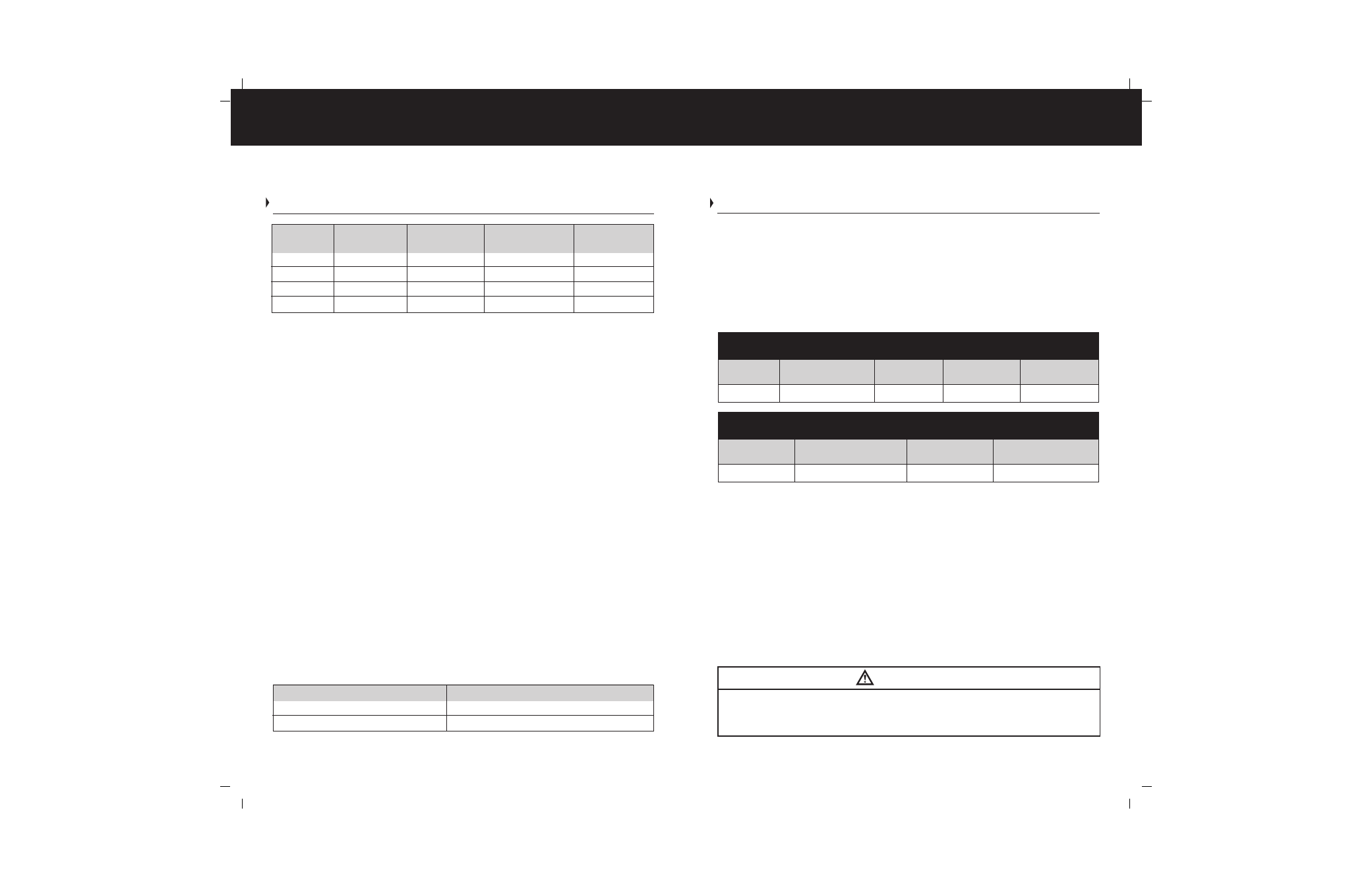

Inverter

12 Volt DC

24 Volt DC

Minimum Cable

Minimum Cable

Wattage

Amp Draw

Amp Draw

Size(AWG) 12V*

Size(AWG) 24V*

1000

100A

N/A

4

N/A

1500

150A

75A

2

6

2000

200A

100A

0

4

2500

250A

125A

00

4

b. Termination - Larger DC cables require specialty tools to ensure proper

termination with ring terminals. Pre-terminated cable kits can be

purchased through ProMariner or your local marine supply store. The

DC stud size is 5/16”. Cable type is as important as size. Cables must be

marine grade and acceptable under ABYC E-11 AC & DC Electrical

Systems on Board Boats (types such as UL 1426 Boat Cable, and SAE

J1127 Battery Cable are common and marked as such)

c. Connection – The ring terminal must be directly on the battery terminal

surface of the DC studs on the TruePower Combi, followed by the washer

and nut with a torque of 10-15 foot-pounds. The use of a dielectric or

anti-oxidant paste is recommended once the cables have been connected.

! DO NOT ATTEMPT CABLE TERMINATION BY MEANS OTHER THAN PROPER

CRIMPING, WITH A PROPERLY CALIBRATED TOOL. SOLDER AND AUTOMOTIVE

REPAIR TYPE BATTERY TERMINALS ARE NOT ACCEPTABLE. USE OF ANY OF THESE

TYPES OF TERMINATIONS WILL RESULT IN PREMATURE, UNWARRANTIED FAILURE

OF THE TRUEPOWER COMBI UNIT.

2) AC Cables – AC Cables should be UL 1426 Boat Cable, per ABYC E-11. This

type of cable is readily available in both 2 and 3 conductor. Size is based on

the maximum amperage to be passed through the cable and unlike DC does

not take into account the length of the cable run and voltage drop. The table

below indicates the proper size for AC Cables.

a. AC Connections – Screw terminals have been provided to connect

the input and output AC cables.

*Based on ABYC E-11 2008 Table VI-A Inside Engine Spaces.

Shore/station power Service

Cable Size (AWG) 105

° C Insulation

30 amp

12

50 amp

10

INSTALLATION MATERIALS – OVERCURRENT PROTECTION

(Fuses and or Breakers)

DC Cable Protection – The purpose of overcurrent protection is to protect the wire from

conducting too much amperage. Fuses and circuit breakers are adequate for this

purpose. The TruePower Combi is protected at the source for charging purposes

internally to the unit. The installer must provide overcurrent protection within 7” of the

point of connection to the positive terminal of the battery. The appropriate amperages

are provided below for both 12 and 24 volt models:

TERMINAL PROTECTION & STRAIN RELIEF

AC Terminals must be protected with the provided cover. This cover also includes grommets

to provide local strain relief on the conductors. The conductors shall also be secured to

structure within 18” of the unit by other means such as straps or wire ties.

DC Terminals must be protected with the provided covers. The covers allow for multi

directional cable installation and should be installed to match the direction of the

incoming cable. The conductors shall also be secured to structure within 18” of the

unit by means such as straps or wire ties.

MAIN PANELBOARD

A True RMS voltmeter must be installed on or in proximity to the main panelboard along

with the following label included with the TruePower Combi:

ANL Ignition Protected Fuses for TruePower Models 12V

Single Position

1000 Watt

1500 Watt

2500 Watt

ANL Fuse Holder

Amperage

100-425 amps

130 amp

175 amp

300 amp

ANL Ignition Protected Fuses for TruePower Models 24V

Single Position

1500 Watt

2500 Watt

ANL Fuse Holder

Amperage

100-425 amps

100 amp

175 amp

WARNING

Electrical Shock Hazard

Vessel is equipped with a DC to AC power inverter

Disconnect inverter DC input before servicing vessel’s electrical systems.