Ii 3d t125°c – NORD Drivesystems BU0310 User Manual

Page 4

4

BU 0310 GB

II 3D T125°C

Instructions for parameterization / Scope of application

As the marking shows, the frequency inverter and the motor are suitable for use in

zone 22 (non-conductive dust).

The marking is as follows:

For zone 2 operation of frequency and motor, cable entries must ensure at least the IP

55 type of protection. Openings which are not in use have to be sealed with dummy

plugs (minimum type of protection IP 55).

The frequency inverter ensures protection of the motor against overheating by

evaluating the PTC resistor of the motor. For this effect to be obtained, digital input 1

must be assigned the "PTC resistor" function (P420 = 13). Be sure, too, to select the

NORD motor you are using from the motor list (P200). When a motor from a different

manufacturer is used the motor parameter data (requested to be set in P201 to P208)

must be copied from the type plate of the motor. Best verify whether the settings of the

respective parameters correspond with the type plate before starting the motor.

Furthermore the frequency inverter should be parameterized so as to prevent the motor

from running at a speed greater than 3000

1

/

min

. For a four-pole motor the ´maximum

frequency´ should be set to a value less than or equal to 100 Hz (P105 ≤ 100). When

you make this setting don´t forget to take the maximum allowable output speed

of the gearbox into account!!!

Also activate the "I²t motor“ control in parameter P535.

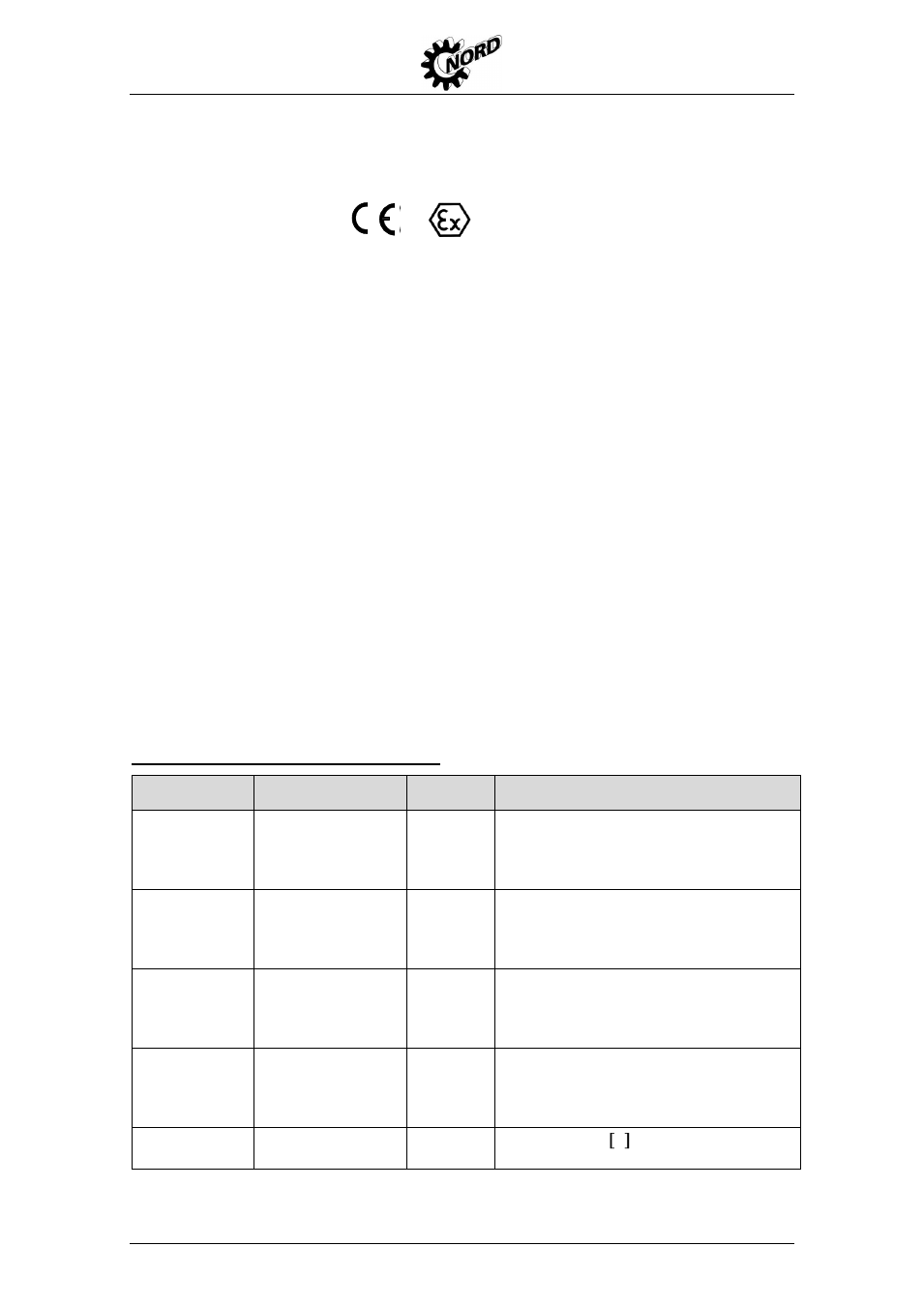

Table of the required parameter settings:

Parameter

Setting value

Default

Description

P105

Maximum

frequency

≤ 100 Hz

[50]

This value is related to a 4-pole motor.

Always select a value that will ensure

that a motor speed of 3000 rpm is not

exceeded.

P200

Motor list

No. from BU 0300

according to the

motor rating

[0]

When a NORD motor is connected,

selecting the appropriate number will

activate the default settings of the

motor used.

P201

– P208

Motor data

Data obtained

from the type plate

[***]

When the motor is from a different

manufacturer, the motor data from the

type plate must be copied to the

applicable parameters.

P420

Function dig.

input1

[13] PTC resistor

input

[13]

Digital input 1 must be parameterized

to ensure the PTC resistor function

and with it temperature control of the

motor.

P535

I²t motor

[1] activated

[0]

The I²t setting 1 for over current

control of the motor is imperative.