Dwyer instruments, inc – Dwyer SVE User Manual

Page 2

INSTALLATION

Warning: Before installation make sure all air pressure

has been released, electric power has been turned off,

and air pressure source has been closed. Turn power on

and increase pressure only after installation is completed.

LOCATION

Select a location that will not exceed the ambient temperature

specifications of the valve. The system must be located in an en-

closure that meets relevant safety standards and electrical codes

of the environment.

MOUNTING

1. Disassemble RSV solenoid valve by removing top nut and wash-

er. Remove solenoid body and finally remove lower nut.

2. Make a hole in the panel that is .76 to .81˝ (19.5 to 20.5 mm) in

diameter. (Panel thickness can be from .04 to.15˝ (1 to 4 mm)).

3. Place valve body/tube through the panel hole from the outside

and tighten down lower nut onto the body threads from the inside.

4. Replace solenoid and washer. Tighten down with top nut to hold

down the solenoid.

The RSV can be mounted in any position. For optimum life and per-

formance it is recommended that the unit be mounted vertically

and upright to reduce the chance of foreign matter accumulating in

the valve. For weatherproof applications it is recommended the

cable gland be positioned face down to avoid possible rainfall or

water from entry.

PNEUMATIC CONNECTIONS

Verify that the supply pressure is within the required specification.

Do not turn on the system before installation is complete. Make

sure that there is no dirt or other particulates between the RDCV

diaphragm valve and the connections of the RSV, remote solenoid

valve, which would cause a restriction of airflow. There should be

no condensed water in the piping. The use of a filter may be re-

quired to avoid this problem. Leak testing should be done prior to

installation only.

WIRING CONNECTIONS

Wire in accordance with the National Electrical Code and local reg-

ulations.

RSV

To aid in the wiring, the solenoid on the RSV may be rotated 360°.

Pre-wired models come standard with 22˝ (55 cm) of 18 AWG wire.

For unwired models it is recommended to use 18 AWG copper

wire rated at 90°C or greater.

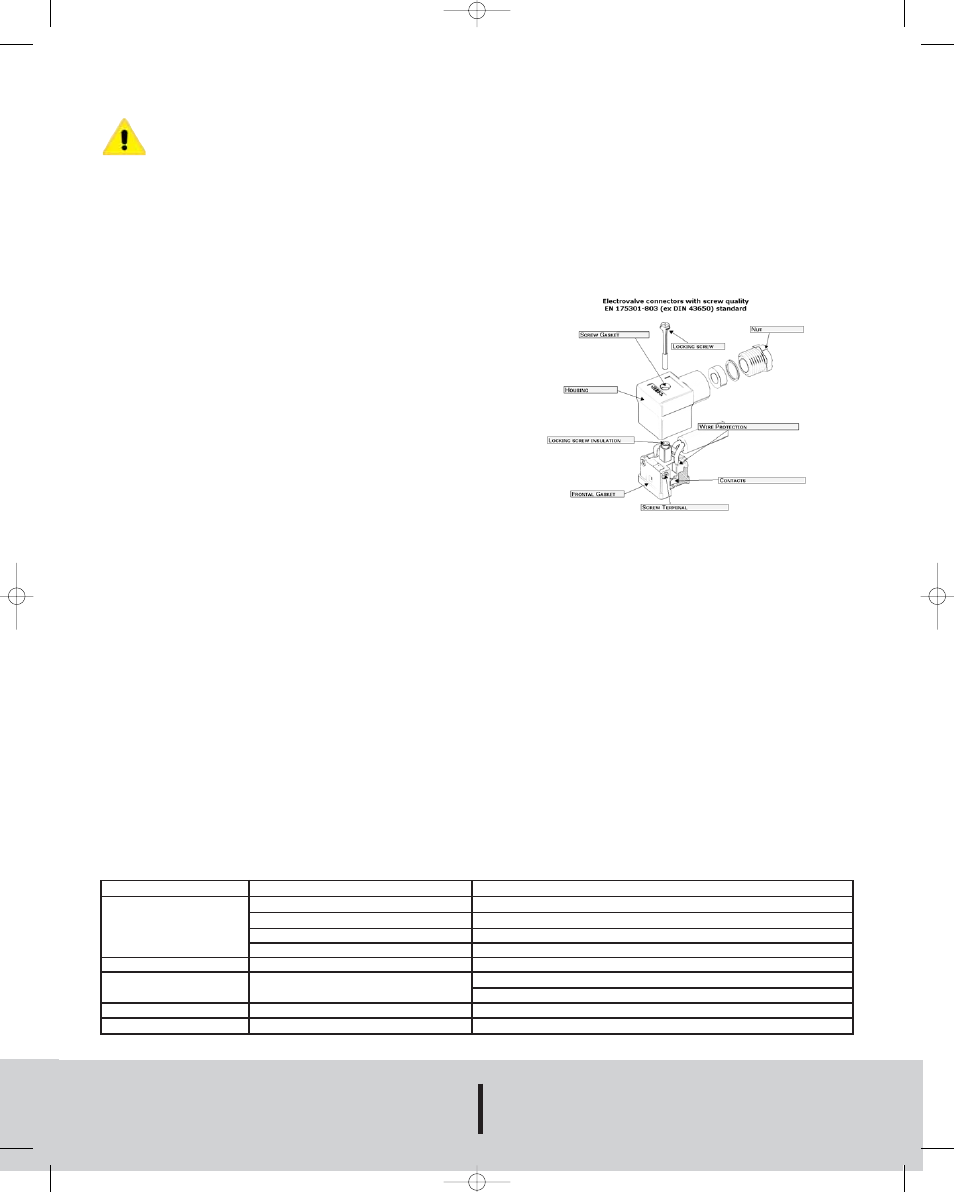

Wiring the RSV with DIN connector. See Figure 1.

1. Remove center screw and pull wiring assembly from the body.

2. Remove gasket and place small screw driver in slot to pry out

the terminal block from the cover.

3. Thread wire through the gland nut, gland gasket, washer and

connector cover.

4. Connect wires to proper terminals on the terminal block.

5. Snap terminal block back into the cover. The connector cover

may be rotated in 90° increments to position the cable entry as

needed for the application. Reinstall the center screw and screw

back into the solenoid body.

Wiring the SVE

The SVE comes from the factory with the RSV solenoids wired to

a terminal block. Connect 18 AWG copper wire rated at 90°C or

greater to the screw terminal block. Ground screw is provided on

the terminal block. The enclosure has a 3/4˝ NPT female conduit

connection. When wiring is complete reinstall cover making sure

that the gasket is in place. Tighten all screws in a crisscross man-

ner.

MAINTENANCE

Warning: To prevent the possibility of death, serious injury or prop-

erty damage, turn off electrical power, depressurize system and

unit, and vent fluid to a safe area before servicing.

The RSV should be cleaned periodically. The amount of time be-

tween cleanings depends on the application. Preventive Mainte-

nance includes keeping media clean of material and oil free, and

periodic testing to insure proper operation and to look for wear or

damage.

WARRANTY

Upon final installation of the Series RSV Remote Solenoid Valve

and the Series SVE Solenoid Valve Enclosure, no routine mainte-

nance is required. A periodic check of the system calibration is

recommended. The Series RSV and Series SVE are not field ser-

viceable and should be returned if repair is needed (field repair

should not be attempted an may void warranty). Be sure to include

a brief description of the problem plus any relevant application

notes. Contact customer service to receive a return goods autho-

rization number before shipping.

©Copyright 2005 Dwyer Instruments, Inc.

Printed in U.S.A. 12/05

FR# R2-443335-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

Problem

No pulse

Leakage in outlet port

Low pulse

Shaking noise

Solenoid noise

Possible Cause

No supply air

Air pressure is too high

No voltage to RSV

Solenoid is damaged

Improper installation of inlet port

Low air pressure

Valve screws are loose

Solenoid mounting screws are loose

Action Required

Check whether the air compressor and valve have been turned on

Check the pressure of the air supply

Check supply voltage

Send back for evaluation

Check the pipe connections between the inlet and outlet

Check air supply pressure

Verify that the air supply was distributed properly

Tighten the loose screws

Tighten the loose screws

Solenoid Valve Troubleshooting

Figure 1

RSV 12/16/05 10:43 AM Page 2