Dwyer 285 User Manual

Page 7

Parameter Mode (PARAM)

Parameter Types

There are four parameter modes: Dead Zone, KP, KI, and KD.

These values are reflected as soon as they are changed, therefore the appropriate

values are found by checking the valve’s motion in real time.

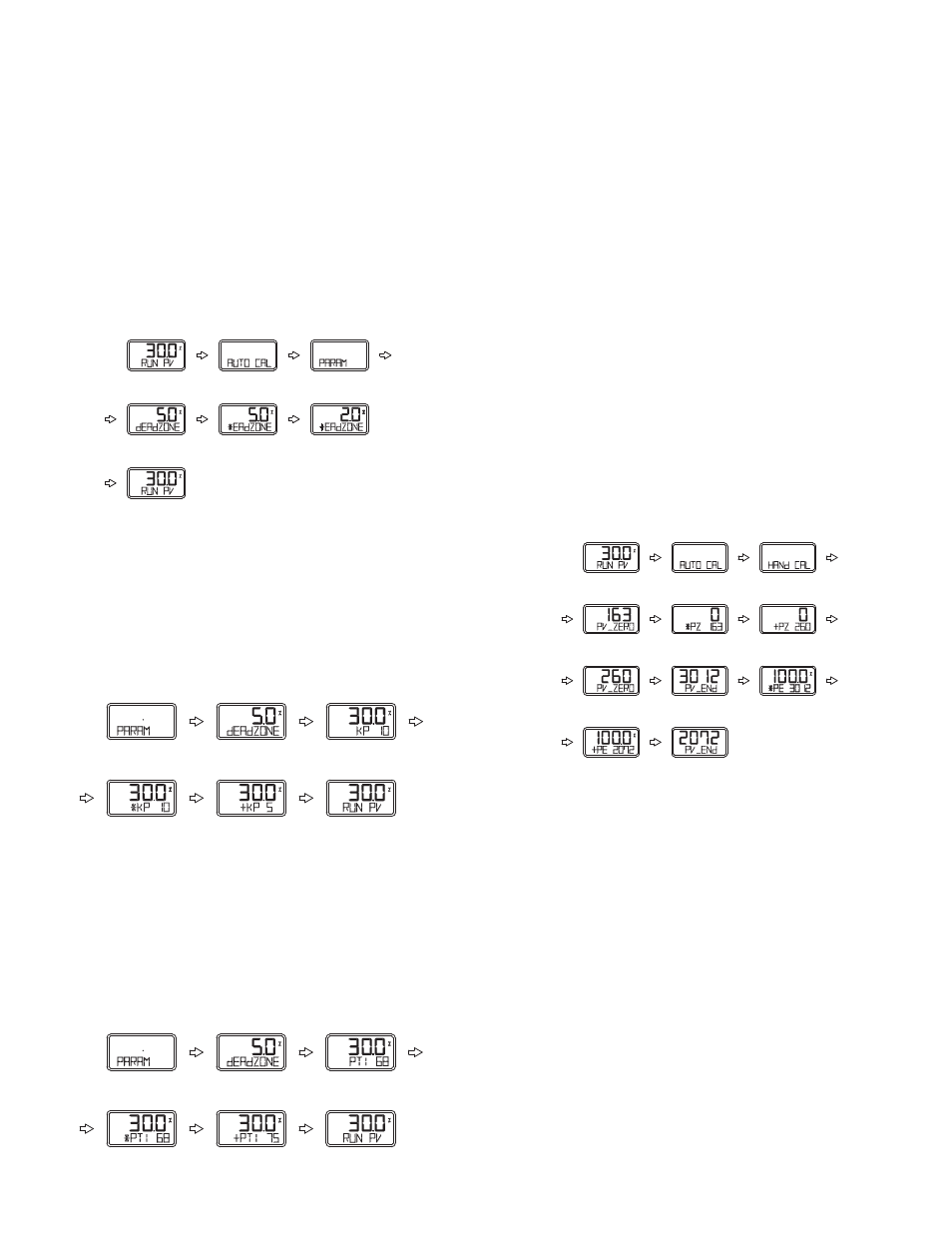

Adjustment of Dead Zone (dEAdZONE)

This is the range of error % that the positioner is not adjusted. Hunting or oscillation

due to friction between the stem and packing is prevented by this parameter.

1. Press and hold

message appears.

2. Scroll with

3. Push

4. Push

5. Adjust dEAdZONE value by pushing

applied immediately without additional operation. Users can easily check its

adjustment by changing the current input signal to the positioner. Optimum

control value is found by adjusting values during the valve operation.

6. Push

7. Push

KP

1. Press and hold

message appears.

2. Scroll with

3. Push

4. Scroll with

5. Push

6. Adjust KP value with

without additional operation. Users can easily check its adjustment by changing

the current input signal to the positioner. Optimum control value is found by

adjusting the values during valve operation.

7. Push

8. Push

PT

1. Press and hold

message appears.

2. Scroll with

3. Push

4. Scroll with

5. Push

6. Adjust PT value with

without additional operation. Users can easily check its adjustment by changing

the current input signal to the positioner. Optimum control value is found by

adjusting the values during valve operation.

7. Push

8. Push

HAND CAL

When auto calibration is started, Series 185 and 285 positioners set zero points

and end points based on full stroke. HAND CAL allows for user defined zero and

end points.

Hand Calibration Types

PV_ZERO: Edit mode to change the zero point of valve.

PV_END: Edit mode to change the end point of a valve.

TR_ZERO: Edit mode to change the zero point of transmitter.

TR_END: Edit mode to change the end point of transmitter.

Adjustment of valve zero point (1 to 5) and end point (6 to 10).

PV_ZERO

1. Press and hold

message appears.

2. Scroll with

3. Push

4. Push

will move automatically to the current zero point. On the LCD, the valve stroke

is displayed as 0%. *PZ indicates the zero point is ready to be set.

5. Adjust valve stem by pushing

desired zero point, save it by pushing

6. Push

PV_END

1. To change valve end point, scroll with

PV_END.

2. Push

will move automatically to the current end point. On the LCD, the valve stroke

is displayed as 100%. *PE indicates the end point is ready to be set.

3. Adjust valve stem by pushing

the desired end point, save it by pushing

4. Push

6 seconds

6 seconds

then

3 times

COMPLETED

3 times

then

3 times

COMPLETED

7 times

then

3 times

COMPLETED

6 seconds

3 times

then

then

COMPLETED