E-98a(low)_2, Dwyer instruments, inc – Dwyer DCT500A User Manual

Page 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

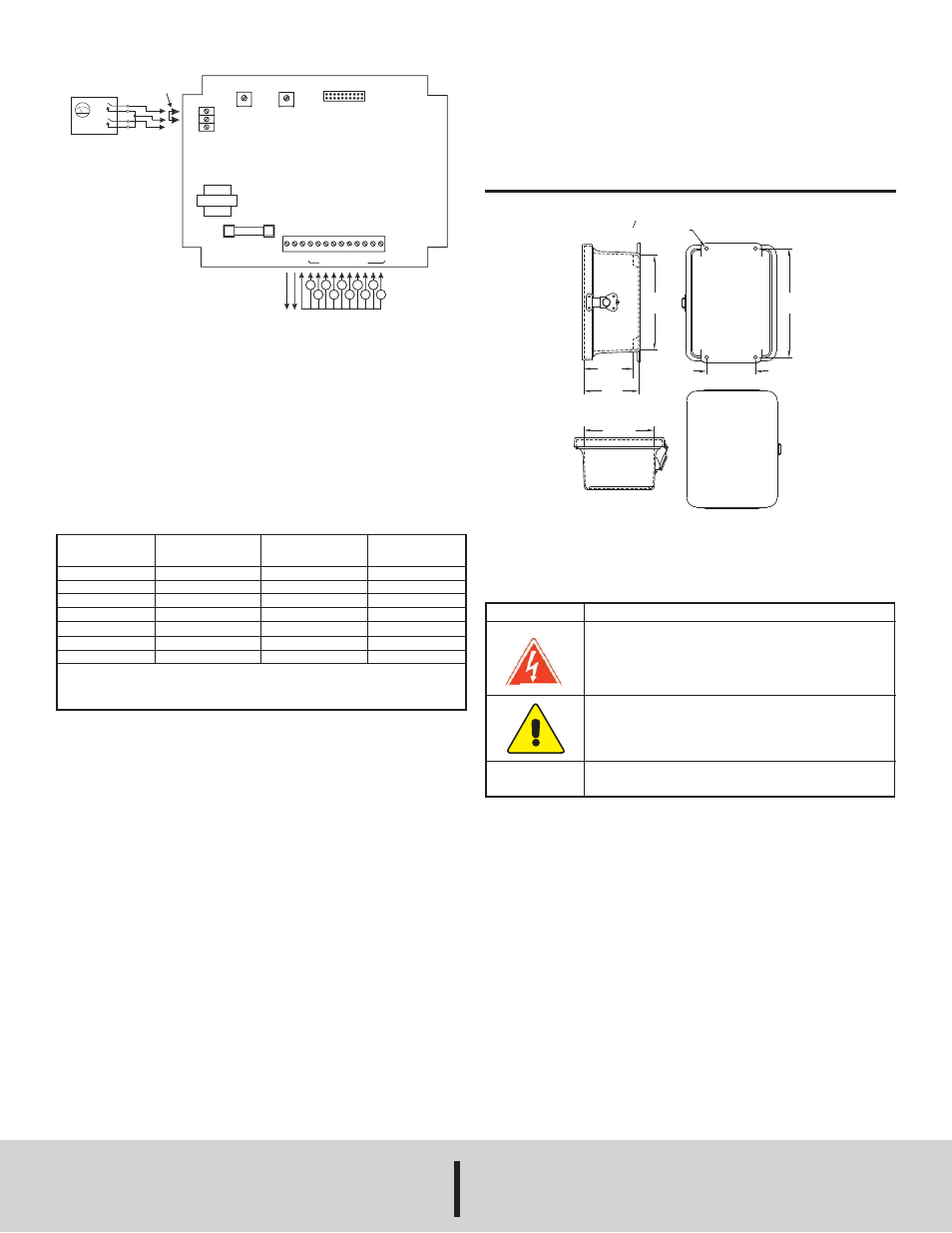

FIGURE 2-1 Switch Connections

External Limit Switch Connection

The controller may be used with an external pressure limit switch or sensor to pro-

vide demand-cleaning operation. A three pin terminal block provides connection for

external high and low limit switches. A simple on-off system can be established with

a single pressure switch connected to the high limit input. Better control can be

achieved with a high and low limit switch/gage such as the Dwyer Photohelic

®

pres-

sure gage. The switches must be isolated contacts between the high or low limit input

and the common connection. The wiring from the switches must be two or three wires

with no other connections made to these. The common line must not be connected

to equipment ground or protective ground, since these may introduce electrical noise

and cause improper operation or possible damage to the control board. The opera-

tion of these inputs is summarized as follows:

Operating Modes

Continuous Cycle Mode

The DCT500A has two operating modes available for different applications. Starting

with the most basic mode, it is capable of operating in a continuous cleaning cycle.

This can be initiated by placing a jumper between the high limit input and the com-

mon connection. Two setup parameters control operation: time off, time on. Time on

and time off specifically deal with the solenoid on time and the time interval between

the end of the on pulse and the start of the next.

Demand Mode

Demand mode operation can be configured using the high limit and low limit inputs.

A simple on-off system can be setup with a single pressure switch connected to the

high limit input. Better control can be achieved with a high and low limit switch set

such as is provided in the Photohelic

®

pressure gage. In this on-demand mode, time

on and time off may be programmed to define the cleaning cycle. When the cleaning

cycle is completed, the controller will continue the cycle until the last channel is

pulsed. The next cleaning cycle will always start on channel 1. A factory installed

option is available that will not clean to the end of the cycle, but rather stop where the

cleaning cycle ended. The next demand for cleaning will start the subsequent chan-

nel where the last cleaning cycle left off.

System Setup

Last Channel Selection

A jumper connector is provided to select the last channel used. Place the jumper on

the two pins corresponding to the last channel used in the installation.

Time Off and Time On Setup

Time off defines the period of time between solenoid activations when no channels

are enabled. This value may be set between 1 second and 200 seconds with a res-

olution of 1 second. Time on defines the solenoid on time. The value may be set

between 50 msec and 500 msec with a resolution of 10 msec. If adjustments are

made while the system is in operation, the new setting will take effect in the follow-

ing solenoid cycle. Do not use excessive force to turn the potentiometers. This will

damage the unit. A factory installed option is available for a time on range of 0.05 to

10 seconds.

SHORT FOR

CONTINUOUS

OPERATION

HIGH

LIMIT

LOW

LIMIT

PRESSURE

LIMIT

SWITCHES

HIGH

LIMIT

LOW

LIMIT

COM

TB2

TIME OFF

TIME ON

CONNECT JUMPER TO

LAST CHANNEL USED

1 2 3 4 5 6 7 8 9 10

L1 L2 SOL 1 2 3 4 5 6 7 8

9 10

COM

OUTPUTS (300VA MAX)

SOLENOIDS

LINE

INPUTS

TB1

©Copyright 2009 Dwyer Instruments, Inc

Printed in U.S.A. 7/09

FR# 05-443180-20 Rev.2

0.31 TYP [7.87]

4 PLACES

7.73

[196.3]

8.88

[225.6]

4.00 TYP

[101.6]

5.74

[145.8]

4.45

[113.0]

4.00

[101.6]

Weatherproof Enclosure Option

Current

Operation

Hold

Hold or Run

Hold

Hold

Run

Hold

Run

Low Limit

Switch

Open

X

Ø

Closed

Closed

Closed

≠

High Limit

Switch

Open

Closed

Open

Ш

≠

Ш

Open

Next

Operation

Hold

Run

Hold

Run

Run

Run

Hold

Ø – Transition from open to closed

≠ – Transition closed to open

X – Either open or closed

Agency Approvals and Test Standards:

UL:

UL508: 2008

IEC 61010-1: 2001-02

CE:

IEC 61000-4-2: 2001

IEC 61000-4-3: 2006

IEC 61000-4-4: 2004

IEC 61000-4-5: 2005

IEC 61000-4-6: 2006

IEC 61000-4-11: 2004

CENELEC EN 55022: 2007

FCC Part 15 CFR Title 47: 2007

ICES-003: 2004 Digital Apparatus (Industry Canada)

ANSI 63.4-2003

CENELEC EN 61326-1: 2006

2004/108/EC EMC Directive

Caution: Risk of electric shock

Caution: Risk of danger, refer to user’s manual for further

information

Description

Symbol

Explanation of Symbols:

Alternating current

~