Dwyer SCD-8 User Manual

Page 2

INA

INB

Content

Explanation

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

Present

temperature

value/input error

code

Unit; 0.1

See Table 5

H1000

(H1100)

H1001

(H1200)

H1002

(H1300)

H1003

(H1400)

H1004

(H1500)

H1005

(H1600)

H1006

(H1700)

H1007

(H1800)

Set temperature

value

Unit: 0.1

H1008

(H1101)

H1009

(H1201)

H100A

(H1301)

H100B

(H1401)

H100C

(H1501)

H100D

(H1601)

H100E

(H1701)

H100F

(H1801)

Max. temperature

value

Disabled when higher

than default value

H1010

(H1102)

H1011

(H1202)

H1012

(H1302)

H1013

(H1402)

H1014

(H1502)

H1015

(H1602)

H1016

(H1702)

H1017

(H1802)

Min. temperature

value

Disabled when lower

than default value

H1018

(H1103)

H1019

(H1203)

H101A

(H1303)

H101B

(H1403)

H101C

(H1503)

H101D

(H1603)

H101E

(H1703)

H101F

(H1803)

Error temperature

value

-999 ~ +999

Unit: 0.1°C

H1020

(H1104)

H1021

(H1204)

H1022

(H1304)

H1023

(H1404)

H1024

(H1504)

H1025

(H1604)

H1026

(H1704)

H1027

(H1804)

Proportional band

value (Pb)

0 ~ 9,999

Unit: 0.1

H1028

(H1105)

H1029

(H1205)

H102A

(H1305)

H102B

(H1405)

H102C

(H1505)

H102D

(H1605)

H102E

(H1705)

H102F

(H1805)

Ti value

0 ~ 9,999

H1030

(H1106)

H1031

(H1206)

H1032

(H1306)

H1033

(H1406)

H1034

(H1506)

H1035

(H1606)

H1036

(H1706)

H1037

(H1806)

Td value

0 ~ 9,999

H1038

(H1107)

H1039

(H1207)

H103A

(H1307)

H103B

(H1407)

H103C

(H1507)

H103D

(H1607)

H103E

(H1707)

H103F

(H1807)

Integration default

0.0 ~ 100.0%

Unit: 0.1%

H1040

(H1108)

H1041

(H1208)

H1042

(H1308)

H1043

(H1408)

H1044

(H1508)

H1045

(H1608)

H1046

(H1708)

H1010

(H1808)

Proportional control

offset error value,

when Ti = 0

0.0 ~ 100.0%

Unit: 0.1%

H1048

(H1109)

H1049

(H1209)

H104A

(H1309)

H104B

(H1409)

H104C

(H1509)

H104D

(H1609)

H104E

(H1709)

H104F

(H1809)

Proportional band

coefficient of output

1 and output 2

0.01 ~ 99.99

Unit: 0.01

H1050

(H110A)

H1051

(H120A)

H1052

(H130A)

H1053

(H140A)

H1054

(H150A)

H1055

(H160A)

H1056

(H170A)

H1057

(H180A)

Dead band of

control output 1 &

output 2.

-99.9 ~ 999.9

H1058

(H110B)

H1059

(H120B)

H105A

(H130B)

H105B

(H140B)

H105C

(H150B)

H105D

(H160B)

H105E

(H170B)

H105F

(H180B)

Hysteresis for

output 1

0 ~ 9,999

Unit: 0.1%

H1060

(H110C)

H1061

(H120C)

H1062

(H130C)

H1063

(H140C)

H1064

(H150C)

H1065

(H160C)

H1066

(H170C)

H1067

(H180C)

Hysteresis for

output 2

0 ~ 9,999

Unit: 0.1%

H1068

(H110D)

H1069

(H120D)

H106A

(H130D)

H106B

(H140D)

H106C

(H150D)

H106D

(H160D)

H106E

(H170D)

H106F

(H180D)

Read/write output

1 value

Unit: 0.1 %

H1070

(H110E)

H1071

(H120E)

H1072

(H130E)

H1073

(H140E)

H1074

(H150E)

H1075

(H160E)

H1076

(H170E)

H1077

(H180E)

Read/write output

2 value

Unit: 0.1 %

H1078

(H110F)

H1079

(H120F)

H107A

(H130F)

H107B

(H140F)

H107C

(H150F)

H107D

(H160F)

H107E

(H170F)

H107F

(H180F)

Upper limit for

alarm output

Alarm enabled

when temperature

exceeds upper limit

H1080

(H1110)

H1081

(1210)

H1082

(H1310)

H1083

(H1410)

H1084

(H1510)

H1085

(H1610)

H1086

(H1710)

H1087

(H1810)

Lower limit for

alarm output

Alarm enabled

when temperature

falls below lower

limit

H1088

(H1111)

H1089

(H1211)

H108A

(H1311)

H108B

(H1411)

H108C

(H1511)

H108D

(H1611)

H108E

(H1711)

H108F

(H1811)

Tuning for upper

limit of analog

output

Current (4 ~ 20mA)

or voltage output

tuning

H1090

(H1112)

H1091

(H1212)

H1092

(H1312)

H1093

(H1412)

H1094

(H1512)

H1095

(H1612)

H1096

(H1712)

H1097

(H1812)

Tuning for lower

limit of analog

output

Current (4 ~ 20mA)

or voltage output

tuning

H1098

(H1113)

H1099

(H1213)

H109A

(H1313)

H109B

(H1413)

H109C

(H1513)

H109D

(H1613)

H109E

(H1713)

H109F

(H1813)

Input sensor type

See “Input” section

H10A0

(H1114)

H10A1

(H1214)

H10A2

(H1314)

H10A3

(H1414)

H10A4

(H1514)

H10A5

(H1614)

H10A6

(H1714)

H10A7

(H1814)

Output function

for output 1

0: heating

1: cooling

2: proportional

output

H10A8

(H1115)

H10A9

(H1215)

H10AA

(H1315)

H10AB

(H1415)

H10AC

(H1515)

H10AD

(H1615)

H10AE

(H1715)

H10AF

(H1815)

Output function

for output 2

0: heating (default)

1: cooling

2: alarm

H10B0

(H1116)

H10B1

(H1216)

H10B2

(H1316)

H10B3

(H1416)

H10B4

(H1516)

H10B5

(H1616)

H10B6

(H1716)

H10B7

(H1816)

Control method

0: PID

1: ON-OFF

2: manual

3: PID

programmable

H10B8

(H1117)

H10B9

(H1217)

H10BA

(H1317)

H10BB

(H1417)

H10BC

(H1517)

H10BD

(H1617)

H10BE

(H1717)

H10BF

(H1817)

Alarm 1 output

mode

See “Alarm Output”

section

H10C0

(H1118)

H10C1

(H1218)

H10C2

(H1318)

H10C3

(H1418)

H10C4

(H1518)

H10C5

(H1618)

H10C6

(H1718)

H10C7

(H1818)

Alarm 2 output

mode

See “Alarm Output”

section

H10C4

(H1518)

H10C5

(H1618)

H10C6

(H1718)

H10C7

(H1818)

Heating/cooling

cycle for output 1

1 ~ 99 seconds

0 = 0.5 second

H10C8

(H1119)

H10C9

(H1219)

H10CA

(H1319)

H10CB

(H1419)

H10CC

(H1519)

H10CD

(H1619)

H10CE

(H1719)

H10CF

(H1819)

Heating/cooling

cycle for output 2

1 ~ 99 seconds

0 = 0.5 second

H10D0

(H111A)

H10D1

(H121A)

H10D2

(H131A)

H10D3

(H141A)

H10D4

(H151A)

H10D5

(H161A)

H10D6

(H171A)

H10D7

(H181A)

Run/Stop the

control

0: stop

1: executing

2: program stops

3: program pauses

H10D8

(H111B)

H10D9

(H121B)

H10DA

(H131B)

H10DB

(H141B)

H10DC

(H151B)

H10DD

(H161B)

H10DE

(H171B)

H10DF

(H181B)

Status of PID

auto-tuning

0: stop

1: executing

H10E0

(H111C)

H10E1

(H121C)

H10E2

(H131C)

H10E3

(H141C)

H10E4

(H151C)

H10E5

(H161C)

H10E6

(H171C)

H10E7

(H181C)

Positive/negative

proportional

0: positive

1: negative (slope)

H10E8

(H111D)

H10E9

(H121D)

H10EA

(H131D)

H10EB

(H141D)

H10EC

(H151D)

H10ED

(H161D)

H10EE

(H171D)

H10EF

(H181D)

INA

INB

Content

Explanation

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

output

Other statuses

Other statuses

H10F0

Temperature

unit

H10F1

Open special

function

(H1234)

H10F2

Return to

default

(H1357)

H10F3

Reserved

H10F4

Reserved

H10F5

Reserved

H10F6

Reserved

H10F7

Reserved

Communication

specifications

See Table 4

H10F8

Auto ID

setup

H10F9

Reserved

H10FA

Baud rate

H10FB

ASCII = 0

RTU = 1

H10FC

8 bits=0

7 bits=1

H10FD

2 stop=0

1 stop=1

H10FE

Parity

H10FF

Address

1 ~ 247

Communication Parameter Setting:

Content

0

1

2

3

4

5

6

Baud rate

2,400bps

4,800bps

9,600bps

19,200bps

38,400bps

57,600bps

115,200bps

Parity bit

None (N)

Even (E)

Odd (O)

Table 4

Error Codes:

The error codes can be read from address H1000 ~ H1007. When the input operation is in normal status, H1000 ~ H1007 are

for input values. When input error occurs (except for stable status and input exceeding the range), SCD8000/8100 will read

error codes in H8001 ~ H8002.

H1000 Error

description

H8001

EEPROM cannot be written in.

H8002

Input sensor is not connected.

H8003

Group INB is not connected.

Table 5

Analog output current tuning scale: 1μA/scale

Analog output voltage tuning scale: 1mV/scale

Returning to Default Value: Write H1234 into address H10F1 and H1357 into address H10F2. Restart SCD8000/8100.

Programmable Communication Parameter Setting:

INA

INB

Content

Explanation

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

Read remaining time of the step

Unit: sec

H111E H121E H131E H141E H151E H161E H171E H181E

Read remaining time of the step

Unit: min

H111F H121F H131F H141F H151F H161F H171F H181F

Read the NO. of the current

pattern

0 ~ 7

H1120 H1220 H1320 H1420 H1520 H1620 H1720 H1820

Read the NO. of the current step 0 ~ 7

H1121 H1221 H1321 H1421 H1521 H1621 H1721 H1821

NO. of start pattern

0 ~ 7

H1122 H1222 H1322 H1422 H1522 H1622 H1722 H1822

NO. of start step

0 ~ 7

H1123 H1223 H1323 H1423 H1523 H1623 H1723 H1823

Programmable Parameter Setting:

Content

Explanation

Pattern

0

Pattern

1

Pattern

2

Pattern

3

Pattern

4

Pattern

5

Pattern

6

Pattern

7

Max. number of

steps in the pattern

0 ~ 7 = N: The pattern

executes from step 0 to

N.

H2068 H2069 H206A H206B H206C H206D H206E H206F

Number of cycles of

pattern 0 ~ 7

execution

0 ~ 199: The pattern

has been executed for 1

~ 200 times

H2070 H2071 H2072 H2073 H2074 H2075 H2076 H2077

NO. of current link

pattern

0 ~ 8: 8 refers to end of

program; 0 ~ 7 refer to

the NO. of next pattern

H2078 H2079 H207A H207B H207C H207D H207E H207F

Address

Default

Content

Explanation

2000H ~ 203FH

0

Target temperatures for pattern 0 ~ 7

Pattern 0: 2000H ~ 2007H

Unit: 0.1°C

2080H ~ 20BFH

0

Execution time for pattern 0 ~ 7

Pattern 0: 2080H ~ 2087H

Time: 0 ~ 900 (Unit: 1 min)

4. Communication format: H03 = read bit data; H06 = write bit data

ASCII Mode:

Read Command

Read Response Message

Write Command

Write Response Message

Start word

’:’

Start word

’:’

Start word

’:’

Start word

’:’

Machine address 1

‘0’

Machine address 1

‘0’

Machine address 1

‘0’

Machine address 1

‘0’

Machine address 0

‘1’

Machine address 0

‘1’

Machine address 0

‘1’

Machine address 0

‘1’

Command 1

‘0’

Command 1

‘0’

Command 1

‘0’

Command 1

‘0’

Command 0

‘3’

Command 0

‘3’

Command 0

‘6’

Command 0

‘6’

‘1’

‘0’

‘1’

‘1’

‘0’

Length of response

data (byte)

‘4’

‘0’

‘0’

‘0’

‘0’

‘0’

‘0’

Read start address of

data/bit

‘0’

‘1’

Data address

‘1’

Data address

‘1’

‘0’

‘F’

‘0’

‘0’

Read length of data/bit

(word/bit)

‘0’

Data content in H1000

‘4’

Write data content

‘3’

Write data content

‘3’

Read Command

Read Response Message

Write Command

Write Response Message

‘0’

‘0’

‘E’

‘E’

‘2’

‘0’

‘8’

‘8’

LRC1 check

‘E’

‘0’

LRC1 check

‘F’

LRC1 check

‘F’

LRC0 check

‘A’

Data content in H1001

‘0’

LRC0 check

‘D’

LRC0 check

‘D’

End word 1

CR

LRC1 check

‘0’

End word 1

CR

End word 1

CR

End word 0

LF

LRC0 check

‘3’

End word 0

LF

End word 0

LF

End

word

1

CR

End

word

0

LF

LRC Check:

Sum up the contents from “machine address” to “data content”, e.g. H01 + H03 + H10 + H00 + H00 + H02 = H16. Obtain

2’scomplement H EA.

RTU Mode:

Read Command

Read Response Message

Write Command

Write Response Message

Machine address

H01

Machine address

H01 Machine

address

H01 Machine

address

H01

Command H03

Command H03 Command H06 Command H06

H10

H10 H10

Read start address of

data

H00

Length of response

data (byte)

H04

Write data address

H01

Write data address

H01

H00

H01 H03 H03

Read length of data

(bit/word)

H02

Data content 1

HF4

Write data content

H20

Write data content

H20

CRC low byte

HC0

H03 CRC

low

byte HDD

CRC low byte

HDD

CRC high byte

HCB

Data content 2

H20

CRC high byte

HE2

CRC high byte

HE2

CRC

low

byte

HBB

CRC high byte

H15

CRC (Cyclical Redundancy Check) is obtained by the following steps:

unsigned int reg_crc = 0xffff;

i = 0;

while (length--)

{ reg_crc ^= RTUData[i];

i ++;

for (j = 0; j < 8; j++)

{ if (reg_crc & 0x01) reg_crc = (reg_crc >> 1) ^ 0xA001;

else reg_crc = reg_crc >> 1;

}

}

return(reg_crc);

Software for Setting up Communication on PC: Download the free software on Dwyer’s website.

10

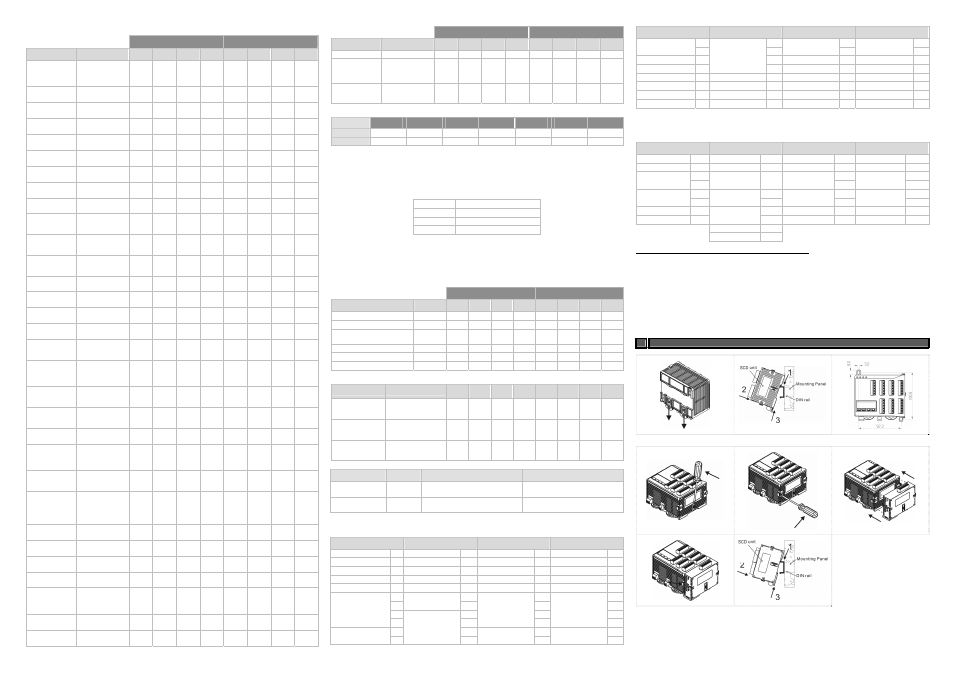

How to Mount & DIN Rail Size

Connect maximum 7 SCD2000 controllers to SCD8000 by using DIN rail.