Mercoid division – Dwyer CRF2 User Manual

Page 4

©Copyright 2012 Dwyer Instruments, Inc.

Printed in U.S.A. 11/12

FR# M1-443559-00 Rev. 6

MERCOID DIVISION

DWYER INSTRUMENTS, INC.

P.O. BOX 258 • MICHIGAN CITY, IN 46360 U.S.A.

Phone: 219/879-8000

www.dwyer-inst.com

Fax: 219/872-9057

e-mail: [email protected]

SETUP & CALIBRATION

Two multi-function buttons are provided for all calibration operations.

With these you can set the zero and span points, adjust the 4 and 20 mA

calibration points, or reset the 4 and 20 mA calibration points to the

factory settings. All settings are stored in nonvolatile memory so they will

not be lost if the power is removed.

Zero and Span Calibration

The zero and span calibration is done with the CRF2 installed in the

measured tank or vessel. Calibrating zero or span can be done in either

order as these settings are independent of one another. The calibration

can be done such that the output can go from 4 to 20 mA or from 20 to

4 mA depending on the desired measurement for full and empty

conditions.

The span or zero calibration is activated by pressing and holding the

corresponding ˝Zero˝ or ˝Span˝ button for three seconds. Set the tank

level to one endpoint (i.e., full or empty), then press and hold either the

Zero or Span button corresponding to the desired endpoint. Set the tank

to the other endpoint then press and hold the opposite Span or Zero

button. Calibration is now complete.

NOTE: Be careful to press the buttons only once within 3 seconds.

Double clicking the switches within 3 seconds will place the unit in

current calibration mode. If this happens press both buttons

simultaneously to exit the current calibration mode. If the calibration was

accidentally changed, the factory calibration can be restored as

described later in ˝Restore Factory Calibration˝.

Current Calibration

The 4 and 20 mA points of the CRF2 have been calibrated at the factory

and generally will not need to be recalibrated, but if needed the points

may be recalibrated. To do this you will need a milliammeter connected

in the current loop.

To calibrate the 4 mA calibration point, ˝double click˝ the Zero/4 mA

button by pressing it twice within 1.5 seconds. The milliammeter will

indicate approximately 4.00 mA. Adjust the 4 mA set point by pressing

the Zero/4 mA button to decrease the current and the Span/20 mA button

to increase the current. When complete, press both the Zero/4 mA and

Span/20 mA buttons simultaneously to exit the calibration mode.

To calibrate the 20 mA calibration point, ˝double click˝ the Span/20 mA

button by pressing it twice within 1.5 seconds. The milliammeter will

indicate approximately 20.00 mA. Adjust the 20 mA set point by pressing

the Zero/4 mA button to decrease the current and the Span/20 mA button

to increase the current. When complete, press both the Zero/4 mA and

Span/20 mA buttons simultaneously to exit the calibration mode.

NOTE: If the buttons are not pressed for approximately 4 minutes in

calibrate mode, the CRF2 will automatically revert to the normal

operation mode.

Restore Factory Calibration

The factory 4 and 20 mA calibration points may be restored by pressing

and holding both the Zero/4 mA and Span/20 mA buttons simultaneously

for 3 seconds. This must be done in the normal operation mode.

MAINTENANCE & REPAIR

Other than the controls mentioned in this manual there are no user

maintenance adjustments or routine servicing required for this product.

The unit is not field repairable and should be returned to the factory if

service is required. Disassembly or modifications made by the user will

void the warrantee and could impair the continued safety of the product.

If repair is required obtain a Returned Goods Authorization (RGA)

number and send the unit, freight prepaid, to the address below. Please

include a detailed description of the problem and conditions under which

the problem was encountered.

When the CLS2 with Sanitary Process Connection is to be used in a

sanitary or hygenic application, the unit must be cleaned and/or

sanitized in accordance with appropriate guidelines prior to installation.

The CLS2 with Sanitary Process Connection is suitable for “Clean In

Place” methods.

Dwyer Instruments Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

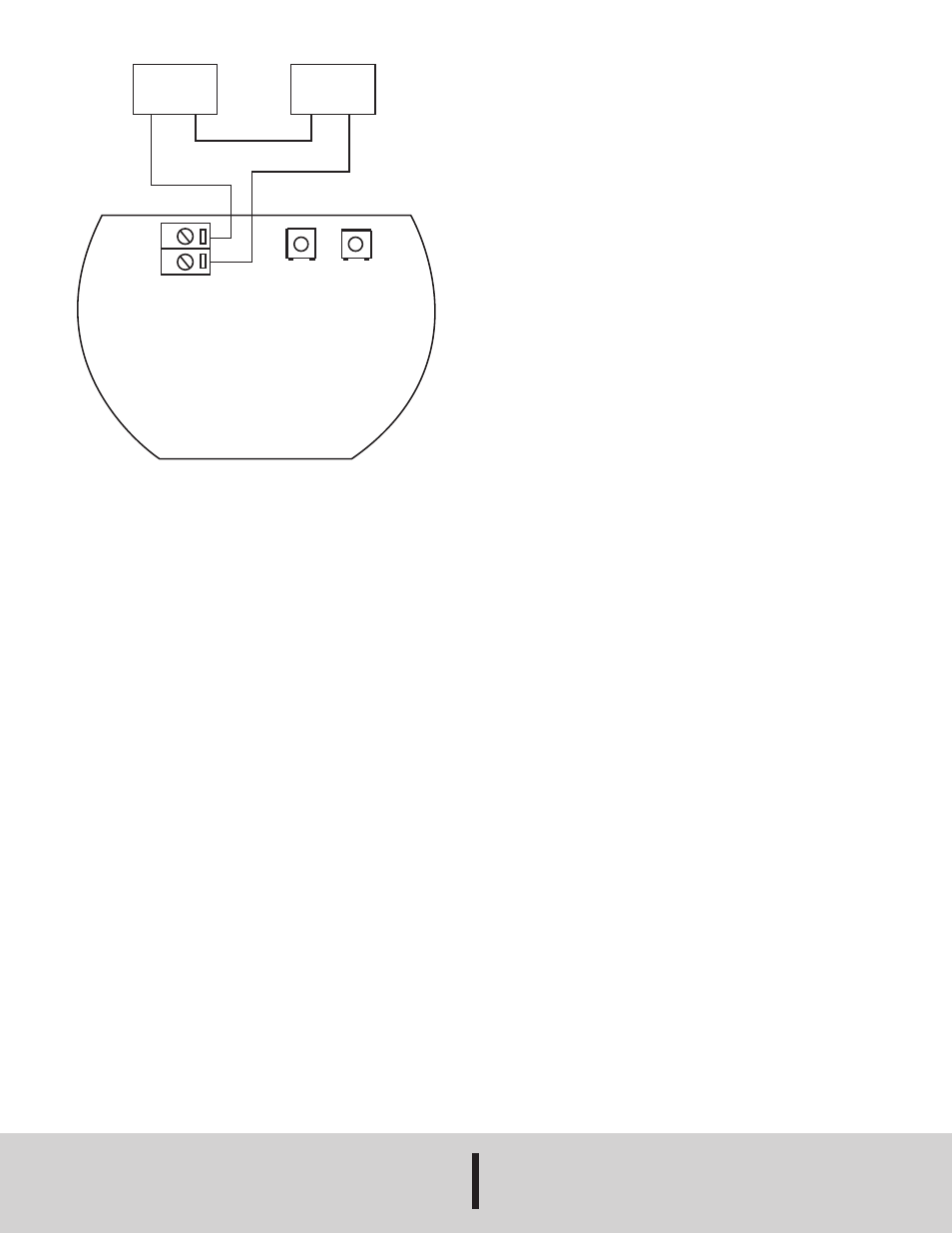

POWER

SUPPLY

RECEIVER/

READOUT

–

–

+

+

ZERO/

4-MA

SPAN/

20-MA

O

U

T

P

U

T

Figure 3: Electrical Wiring Diagram