Wiring diagrams, Calibration, Troubleshooting – Dwyer CLT User Manual

Page 2

Note: For hazardous area applications, use an appropriate intrinsically safe interface device.

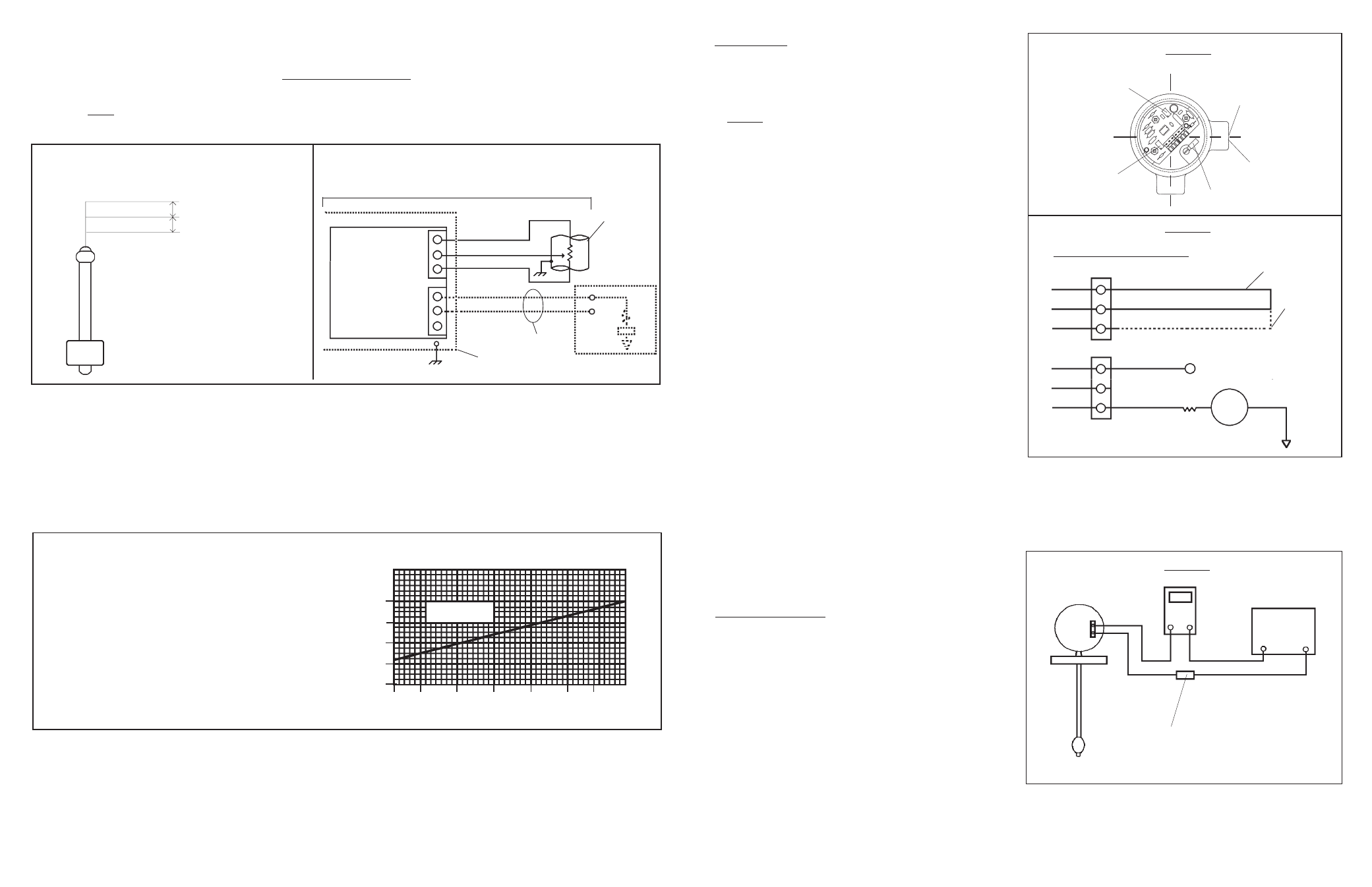

Wiring Diagrams

Calibration should be performed with the probe

disconnected from the signal conditioner. Turn

off power to loop. Disconnect the red, black and

white wires from terminals 1, 2, and 3.

Adjust both the null and span potentiometers at

approximately mid-range. (Figure 1)

Wire as shown per Figure 2, connecting a jumper

wire in place of the black and white probe wires.

Connect an ammeter in series to monitor loop

current. Apply power to loop. Adjust null pot for

4mA.

Remove power from loop. Reposition the jumper

wire in place of red and white probe wires.

Reapply power and with the span pot, set the

output current to 20mA.

Repeat Steps C and D for final adjustment.

If power is maintained during jumper connections,

current level may increase to 36mA. This is

normal. Current will return to regular readings

when connections are made.

Calibration

The signal conditioner on your CLT has been Factory-

set. You do not need to calibrate.

Troubleshooting

Verify proper wiring, power supply, and loop resistance. If

transmitter is not functioning properly, isolate the transmitter

from the system and wire per Figure 3. Meter should read

4mA with float at bottom and 20mA with float on top of

transmitter. If unit is still not operating properly, please

consult Factory for further troubleshooting details.

A.

B.

C.

D.

E.

F.

Steps:

Excitation Required for Transmitters

Using 4-20 mA Signal Conditioners

The minimum excitation required for operation of

transmitters with 4-20 mA, DC signal converters

(See Chart) can be determined for a given total loop

resistance from the graph shown. (Total loop resis-

tance = the sum of the DC termination resistance plus

loop resistance.) For optimum operation, which is a

function of source voltage (+V

A

) and total loop resis-

tance, the source voltage value used should be above

the minimum load line for the related loop resistance.

Area

of Operation

DC Source Voltage

40

30

R

L

(Ohms) Termination Plus DC Loop Resistance

0 200 400 600 800 1000 1200

Minimum Excitation Required For Loop Resistance

20

10

0

Wiring Diagram

Analog Output (Proportional Voltage)

Output: Proportional

Voltage

Wiring Diagram

(4-20mA Output)

Input: 10 - 30 VDC

Red

Black

White

Transmitter

or

Simulator

Junction

Box

4-20 mA Tank Level Transmitter

1

Red

Wht

Blk

Process

Control

Loop

+VA

Voltage

Source

3

2

4

5

6

R

L

1/2" Trade Size

(both Ports)

Span

Potentiometer

Null

Potentiometer

Customer Wiring

(See Wiring Diagram)

Ground Terminal

Figure 1

Figure 2

1

5

Red

White

Black

Brown

Wht/Blk

Orange

Using 300 Ohm Resistor

Place Jumper

Here for 4 mA

Output

Place Jumper

Here for 20 mA

Output

+V (Typically 24V)

Ammeter

R

Loop

+

_

3

2

6

4

Figure 3

+24V

Return

4.12

AMMETER

COM

mA

Power Supply

(24 VDC)

+

_

Choose loop resistance (RL)

to match application