0 calibration, 0 maintenance/repair, 0 electrical installation – Dwyer 682 User Manual

Page 2: 0 series 682 performance specifications

2

3

4.0 CALIBRATION

Every Series 682 is factory calibrated and should require no field adjustment

Whenever possible, any zero and/or span offsets should be corrected by software

adjustments in the user’s control system. However, both zero and span adjustments

are accessible by removing the pan head screws and turning the zero and span

potentiometer screw inside. Use zero and span adjustments on the 682 only if

absolutely necessary. Pan head screws should be replaced after adjustment to

maintain enclosure rating.

Current output units (4-20 mA) are factory calibrated with a 24 VDC loop supply

voltage and a 250 ohm load. The zero factory setting is

±

0.08 mA. The span (full

scale) factory setting is

±

0.16 mA. Zero and span adjustments are approximately

±

1.0 mA.

5.0 MAINTENANCE/REPAIR

After final installation of the Series 682 pressure transducer no routine maintenance

is required. A periodic check of system calibration is recommended. These devices are

not field repairable and should be returned to the factory if recalibration or other

service is required. After first obtaining a Return Goods Authorization (RGA) number,

send the material, freight prepaid, to the following address. Please include a clear

description of the problem plus any application information available.

Dwyer Instruments

Attn: Repair Department

102 Indiana Highway 212

Michigan City, IN 46360

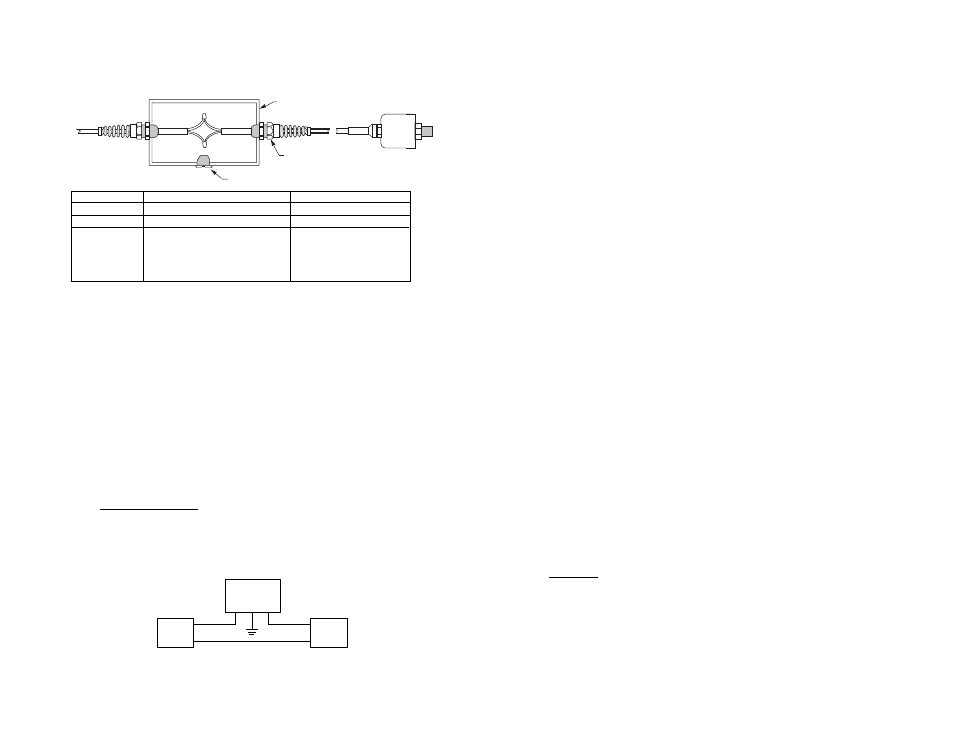

3.0 ELECTRICAL INSTALLATION

The Series 682 is available with the following electrical termination:

2 foot Cable

3.1 Series 682

Series 682 Current Unit

The Series 682 (current output) transducers are true 2-wire, 4-20 mA current output

devices and deliver rated current into any external load of 0-800 ohms. The 682 has a

2-wire cable where red is positive and black is negative. On the Hirschmann

Connector, Pin 1 is positive; Pin 2 is negative and Pin 4 is Ground/Shield.

Junction Box Suggestion - The following junction box configuration is a

recommended method of terminating the 682 signal cable in order to achieve

a moisture resistant and vented connection.

Termination:

Junction Box

Cable Strain Relief

Part No.

Q1388PCE

3237 Heyco Flex Fitting

Dimensions:

4.92” x 2.95” x 2.95”

2.50” Long

Manufacturer:

Hoffman Engineering Co.

Heyco

900 Ehlen Drive

Kenilworth, NJ 07033

Anoka, MN 55303

(201) 245-0033

(612) 421-2240

(800) 526-4182

1. Drill one 1/2” dia. hole at each end of junction box for cable strain reliefs.

Note: If conduit is to be installed, omit one 1/2” hole and drill appropriate

hole for conduit.

2. Drill and tap one 1/2” - 13 NC hole in bottom of junction box and install

loosely one 1/2” - 13 NC plastic or stainless steel screw. The clearance

between threads serves as a vent for the box.

3. Install cable strain reliefs in 1/2” dia. holes. If using conduit at one end, be

sure it is sealed properly against moisture.

4. Mount junction box and install cables.

5. A desiccant pack can be placed in the junction box for additional protection.

Series 682

Transducer (4-20

mA)

Power

Supply

Load

(Monitor)

+

+

+

_

_

_

The 4-20 mA current output unit is designed to have current flow in one direction only -

PLEASE OBSERVE POLARITY. We suggest that the electrical cable shield be connected to

the system’s loop circuit ground to improve electrical noise rejection.

Vent Screw

Plastic Junction Box

Strain Relief

206/C206

6.0 SERIES 682 PERFORMANCE SPECIFICATIONS

Accuracy RSS

*

±

0.13% FS

(at constant temperature)

Non-Linearity, BFSL

±

0.1% FS

Hysteresis

0.08% FS

Non-Repeatability

0.02% FS

*RSS of Non-Linearity, Non-Repeatability and Hysteresis.

Thermal Effects

Compensated Range

°

F(

°

C)

-4 to +176 (-20 to +80)

Zero Shift %FS/

°

F(

°

C)

±

1.0 (

±

0.9)

Span Shift %FS/

°

F(

°

C)

±

1.5 (

±

1.4)

Stability

0.5% FS/YR