Dwyer A2 User Manual

Page 2

Maintenance/Repair

Regular maintenance of the total system is recommended to assure sus-

tained optimum performance. These devices are not field repairable and should

be returned to the factory if recalibration or other service is required. After first

obtaining a Returned Goods Authorization (RGA) number, send the unit freight

prepaid to the following. Please include a clear description of the problem

plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

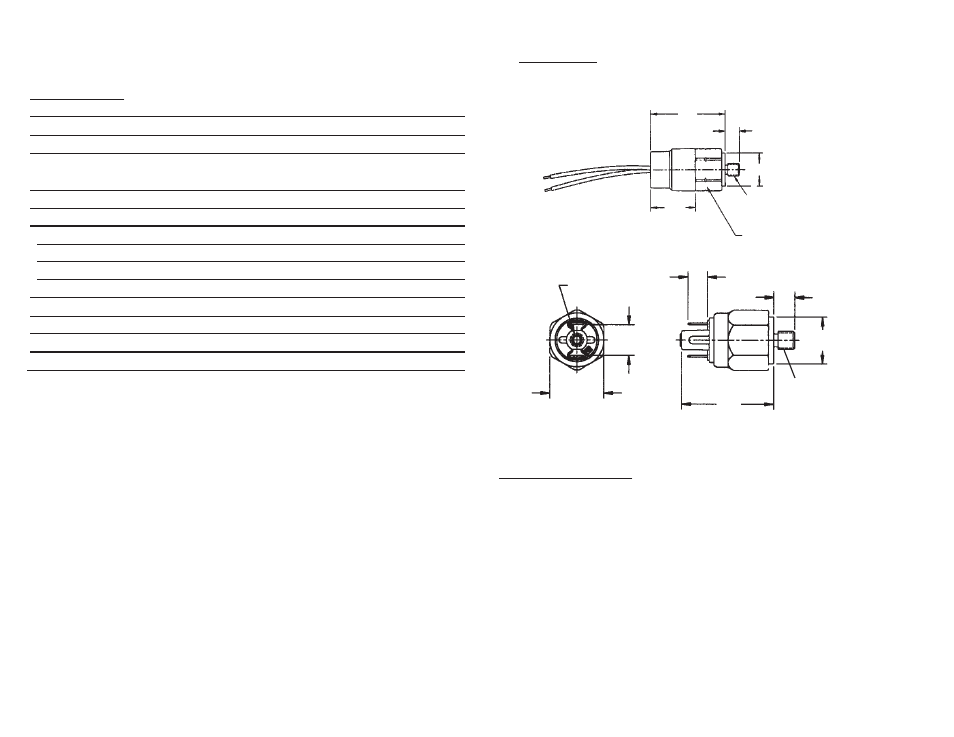

.054”

(14)

1/8 ALLEN WRENCH

ADJUSTMENT SCREW

15/16” A.F.

(24)

1.67”

(42.5)

.35”

( 9 )

.35”

( 9 )

SEE

ORDERING

INFORMATION

∅

.82”

(

∅

21)

SEE

ORDERING

INFORMATION

∅

.82”

(

∅

21)

.35”

( 9 )

1.95”

(50)

1.12”

(29)

HEX 15/16”

(24)

The pressure switch is designed and manufactured in accordance

with Sound Engineering Practice as defined by the Pressure

Equipment Directive 97/23/EC. This pressure switch must not be

used as a “safety accessory” as defined by the Pressure Equipment,

Article 1, Paragraph 2.1.3.

The CE Mark on the unit does not relate to the Pressure Equipment

Directive.

Specifications

Process Temperature

-4°F to +250°F (-20°C to +120°C)

Ambient Temperature

-40°F to +250°F (-40°C to +120°C)

Switch

SPST, 100 VA, 42V max.

(>2 million

cycles @ 1,000 psi, max. 200 cycles/min.)

Approvals

CE

Repeatability

5% of Highest Set Point @ 70°F (20°C)

Wetted Parts

Diaphragm

Kapton®

Fitting

Brass

Electrical Termination

6.3mm (1/4”) Spade or Screw Terminals

Process Fitting

G or NPT 1/4”(optional 1/8”)

Deadband

1-2 psi

Proof Pressure

500 psi (34.5 bar)

Weight, Approximate

0.14 lbs. (0.06 kg)

Dimensions

Submersible Option