Dwyer instruments, inc – Dwyer DSGT User Manual

Page 4

Step 2: Press the s (up arrow key) or t(down arrow key) until the word

GRAPH appears.

Step 3: Press ENTER. The gage display will indicate the full-scale pres-

sure range setting on the top line. The middle line indicates the bar graph

at 100% of full-scale. The bottom line of the display will indicate SETFS

to set the full-scale range for the bar graph and transmitter output.

Step 4: Press the s (up arrow key) or t(down arrow key) on the keypad

to increase or decrease the full-scale value.

Step 5: Press ENTER to finalize the setting. The gage display will now

display SET. After two seconds the screen will display the pressure value

for 0% of the bar graph on the top line. The middle line indicates the bar

graph at 100% of full-scale. The bottom line will display SET 0.

Step 6: Press the s (up arrow key) or t(down arrow key) on the keypad

to increase or decrease the 0% pressure value.

Step 7: Press ENTER to finalize the setting. The new pressure values

for 0 and 100% of the bar graph and 4 and 20 mA of the transmitter out-

put have now been saved.

OFF: This option sets the amount of time before the gage will turn itself

off. The available options include NEVER (default), 30MIN, 10MIN,

5MIN, and 2MIN.

To use the OFF option:

Step 1: Press the MENU key on the keypad.

Step 2: Press the s (up arrow key) or t(down arrow key) until the word

OFF appears.

Step 3: Press ENTER.

Step 4: Press the s (up arrow key) or t(down arrow key) to select the

desired OFF time.

Step 5: Press ENTER to finalize the OFF selection.

UPDATE: This option allows for changing the rate at which pressure is

updated on the display screen. This feature is useful with rapid changes

in the process pressure that may cause the display to flutter. The avail-

able options include display updates every 100MS (default), 1SEC,

500MS, and 200MS.

Note: Due to the variation in processes, the UPDATE rate should be spe-

cific to the application.

To use the UPDATE option:

Step 1: Press the MENU key on the keypad.

Step 2: Press the s (up arrow key) or t(down arrow key) until the word

UPDATE appears.

Step 3: Press ENTER.

Step 4: Press the s (up arrow key) or t(down arrow key) to select the

desired update rate.

Step 5: Press ENTER to finalize the selection.

DAMP: This is a damping option that allows process pressure readings

to be averaged. This option is particularly useful to stabilize minor

process pressure fluctuations. The available options include averaging

NONE (default), AVG 8, AVG 6, AVG 4, or AVG 2 readings at a time.

To use the DAMP option:

Step 1: Press the MENU key on the keypad.

Step 2: Press the s (up arrow key) or t(down arrow key) until the word

DAMP appears.

Step 3: Press ENTER.

Step 4: Press the s (up arrow key) or t(down arrow key) to select the

desired dampening option.

Step 5: Press ENTER to finalize the selection.

Note: The following MENU item is only seen on gages with the switch

options –C1S or –C2S.

SWSET: This menu item allows for setting of the switch set-points. The

gage is offered with one (-C1S) or two (-C2S) SPDT switches. If one

switch was ordered, the menu option is SW1. If two switches were

ordered, the MENU options are SW1 and SW2.

To use the SWSET menu item:

Step 1: Press the MENU key on the keypad.

Step 2: Press the s (up arrow key) or t(down arrow key) to select the

switch to be set, either SW1 or SW2.

Step 3: Press ENTER. The top line of the gage display will indicate the

most recent switch set-point. The middle line of the display will indicate

a bar graph that displays the set-point as a percentage of the gage’s full-

scale pressure range. The bottom line will display SETPT (blinking).

Notes: The default switch setting is 60% of the calibrated range. Set

points are limited to the full-scale pressure range of the gage.

Step 4: Press the s (up arrow key) or t(down arrow key) to increase or

decrease the set-points.

Step 5: Press ENTER to finalize the set-point selection. The gage will

display SET. After two seconds, the top line will indicate RETRP pressure

and the bottom line will read SET.

Step 6: Repeat steps 4 and 5 to set RETRP which is the reset point of

the switch. If the gage is supplied with one switch, the screen will

advance to the measurement mode. If two switches are supplied the dis-

play will advance to SW2.

Step 7: If the gage has two switches, repeat steps 4, 5, and 6 for SW2.

Notes: The bar graph will increase or decrease as any set-point pressure

is adjusted. The bar graph indicates switch set-point position within the

full-scale pressure range of the gage.

The switch set-point units correspond to the current engineering units set

on the gage. If the selected engineering unit is changed after the switch

set-points are set, the set-points will automatically be updated to corre-

spond with the revised engineering unit.

The dead band for each switch is defined as difference between the

SETPT (set-point) and the RETRP (reset point) pressures.

TROUBLESHOOTING

MAINTENANCE

After final installation of the Series DSGT Indicating Transmitter, no rou-

tine maintenance is required. A periodic check of system calibration is

suggested. These devices are not field repairable and should be

returned if repair is required (field repair should not be attempted and

may void the warranty). Contact customer service to receive a Return

Goods Authorization (RGA) number before shipping. Be sure to include

a brief description of the problem plus any relevant application notes.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 4/14 FR# R9-443332-00 Rev. 4

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. Box 373 • Michigan City, IN 46360 U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

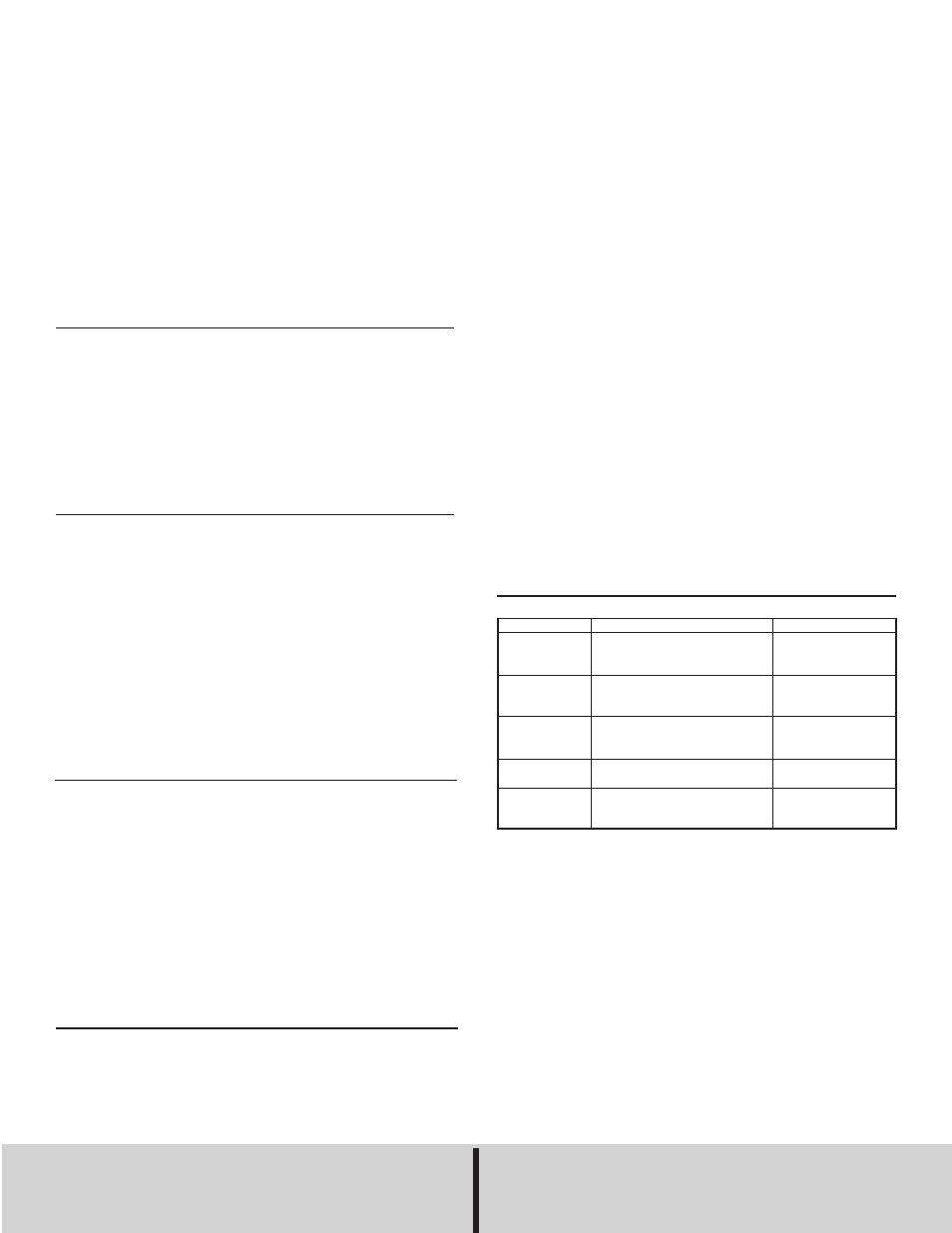

Action

Only re-zero the gage

within limits of the

ObUTN feature.

Push MAX/MIN key to

return to measurement

mode.

Choose another

engineering unit.

Select a different

password

Enable item(s) in Menu

under CONFIG/diSAb

Display/Problem

OFSET

(blinking)

MENU button

disabled

Engineering unit

selected in Menu

displays N/A

Desired password

can’t be set

Main menu

items can’t be

accessed

Description

ZERO/CLEAR button pushed when

pressure displayed is beyond set

re-zero pressure limit.

Gage is in MAX/MIN mode.

Resolution at full-scale pressure

exceeds 50,000 count.

00000 is not a

valid password.

Items that can’t be accessed

have been disabled.