Dwyer 7314D User Manual

Dwyer instruments, inc, Never put stress on housing, Bulletin a-33-b

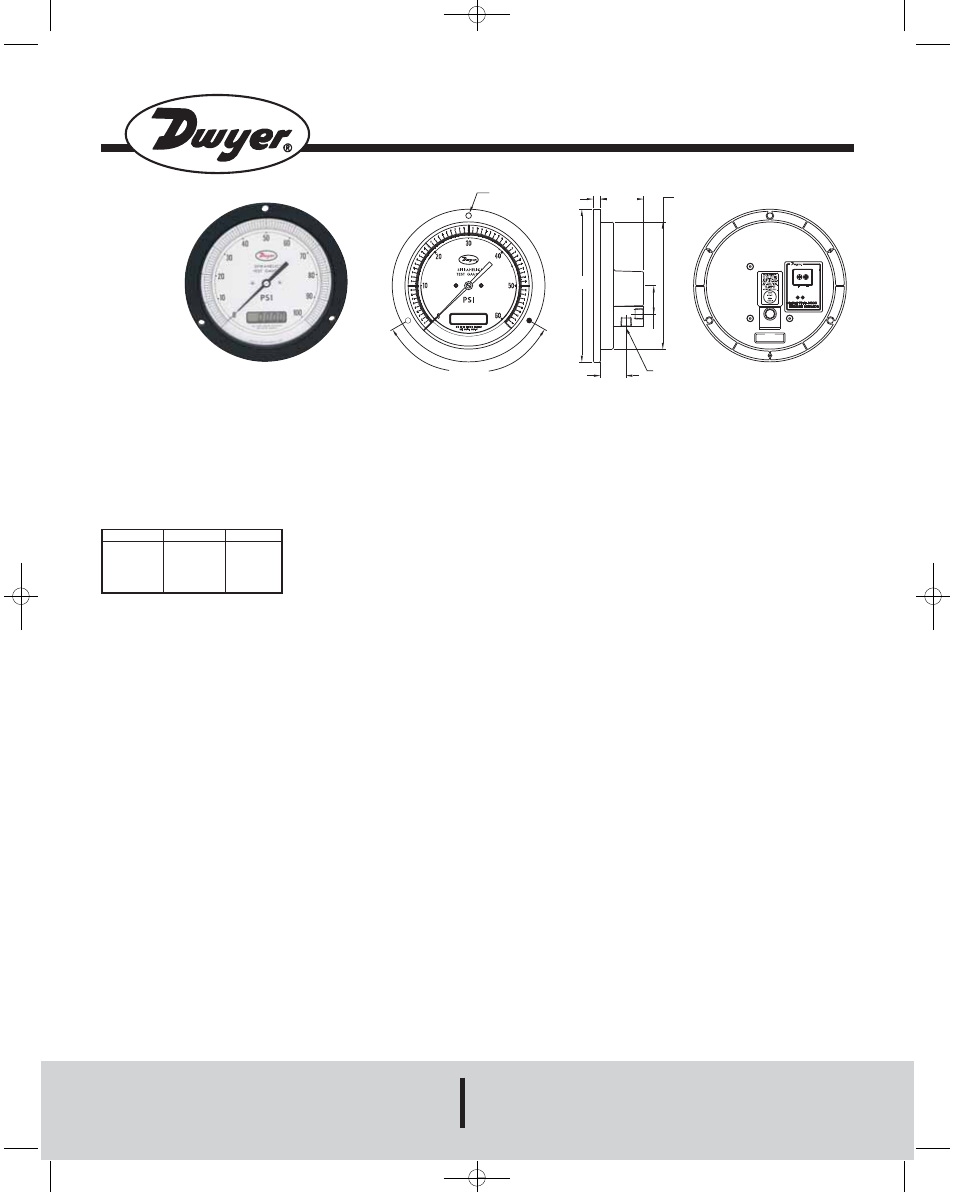

SERIES 7214D & 7314D

SPIRAHELIC

®

PRESSURE GAGE WITH DIGITAL DISPLAY

Specifications - Installation and Operating Instructions

Bulletin A-33-B

B

11/32

[8.732]

2-9/64

[54.37]

1-13/32

[35.71]

1/4 NPT TYP 2 PLACES

1-9/32

[32.54]

C

A

120° TYP.

CAUTION

ALWAYS USE WRENCH ON PRESSURE

BLOCK WHEN TIGHTENING FITTINGS

ZERO

SPAN

NEVER PUT STRESS ON HOUSING

DWYER INSTRUMENTS, INC.

MICHIGAN CITY, IN 46360, U.S.A.

Inconel

®

is a registered trademark of Huntington Alloy Corporation

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

Series 7214D & 7314D Models and Ranges

Model

7214D-G100

7214D-G200

7214D-G300

7214D-G600

Model

7314D-G100

7314D-G200

7314D-G300

7314D-G600

Range, PSI

0-100

0-200

0-300

0-600

SPECIFICATIONS

Size: 6˝ (7214D), 8.5˝ (7314D). Size conforms to ASME B40.1.

Accuracy: ASME Grade 3A (1/4% of full scale).

Pressure Connections: 1/4˝ NPT female, duplicated back and bottom.

ASME Specifications: Conforms to ASME B40.1.

Housing: Impact resistant mineral filled nylon.

Position: Calibrated for mounting with scale in vertical position.

Wetted Parts: Inconel

®

Alloy X-750 Bourdon tube, 316 SS connection block.

Movement: Direct drive of pointer.

Temperature Limits: 20 to 120°F (-6.7 to 48.9°C).

Overpressure: 150% of full scale. Recommended operation should be between

25 and 75% of full scale.

Finish: Black.

Weight: 7214D-21 oz. (595 grams) 7314D-1 lb, 11 oz. (765 grams) .

Accessory: (1) 1/4˝ NPT pipe plug.

Electrical

Power Supply: 10-35 VDC; 16-26 VAC.

Warm-Up Time: 10 minutes.

Current Consumption: DC: 38 mA max.; AC: 76 mA max.

Series 7214D & 7314D Dwyer

®

Spirahelic

®

Gages employ a unique triple-wound

helical/spiral Bourdon tube, formed from Inconel

®

Alloy X-750 material for excep-

tionally wide media compatibility and reliability. Units provide ASME Grade 3A

accuracy (1/4%), readable on both a large 6˝ (7214D), 8.5˝ (7314D) analog dial

and a 4-1/2 digit liquid crystal display. A 316 SS connection block includes dual 1/4˝

NPT female ports for a choice of vertical or horizontal piping. Block includes an

integral filter plug to prevent dirt or other foreign material from entering the gage.

Gage fits standard ASME 9.0˝ (229mm) panel cut out.

Installation

1. Select a location free from excess vibration where the temperature limits of 20

to 120°F (-6.7 to 48.9°C) will not be exceeded. Mounting surface should be verti-

cal to match the position in which all standard gages are calibrated. Avoid locations

in direct sunlight which can cause accelerated discoloration of the clear acrylic

lens or where exposure to oil mist or other airborne vapors could likewise result in

lens damage. Make sure the case relief area on the rear is not obstructed. This

hole is designed to direct pressure rearward in the event of a Bourdon tube failure.

See complete safety recommendations on the back of this sheet.

2. Make a panel cutout of 6.5˝ (165.1mm) for Series 7214D gages. Make a panel

cutout of 9˝ (229mm) for Series 7314D gages. See drawing above for bolt circle

diameters and bolt hole sizes.

3. Two 1/4˝ NPT female pressure connections are provided allowing a choice of

vertical (below gage) or horizontal piping. Plug unused port. Use minimal amount

of thread sealant. Too much could block the internal pressure passage.

Caution: When installing fittings or pipe, always use a second wrench on the 1˝

connection block. Do Not allow torque to be transmitted from the block to the gage

case.

Electrical Connections

Caution: Do not exceed specified supply voltage ratings.

Permanent damage not covered by warranty will result.

This unit is not designed for 120 or 240 VAC line operation.

Electrical connections to the Series 7214D & 7314D Spirahelic

®

Pressure gage

with digital display are made to the electrical terminal strip on the rear of the case.

See drawing above. It is not necessary to observe polarity when making electrical

connections. Do observe the maximum VDC and VAC limits listed at left.

Calibration Test

To check calibration, use a dead weight tester or certified test gage with accuracy

of 0.1% or better for ASME Grade 3A gages. The test gage range should be com-

parable to the range of the Dwyer

®

Spirahelic

®

gage being tested. Connect lines

from the two instruments to a tee and a third line from the tee to a controllable

source of pressure. Apply pressure slowly so pressure can equalize throughout the

system. Compare readings. If gage being tested is found to need calibration,

return it freight prepaid to the address below.

Maintenance

No lubrication or periodic servicing is required. Keep case exterior and lens clean.

Use only cleaners compatible with acrylic plastic.

Repairs

Field repair is not recommended and can void warranty. Gages needing calibration

or other service should be returned freight prepaid to:

Dwyer Instruments, Inc.

Attn: Repair Department

102 Indiana Highway 212

Michigan City, IN 46360

A-33-B :7314D IOM 3/1/11 8:41 AM Page 1