Dwyer instruments, inc – Dwyer 647 User Manual

Page 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

©Copyright 2014 Dwyer Instruments, Inc.

Printed in U.S.A. 2/14

FR# 443017-00 Rev.1

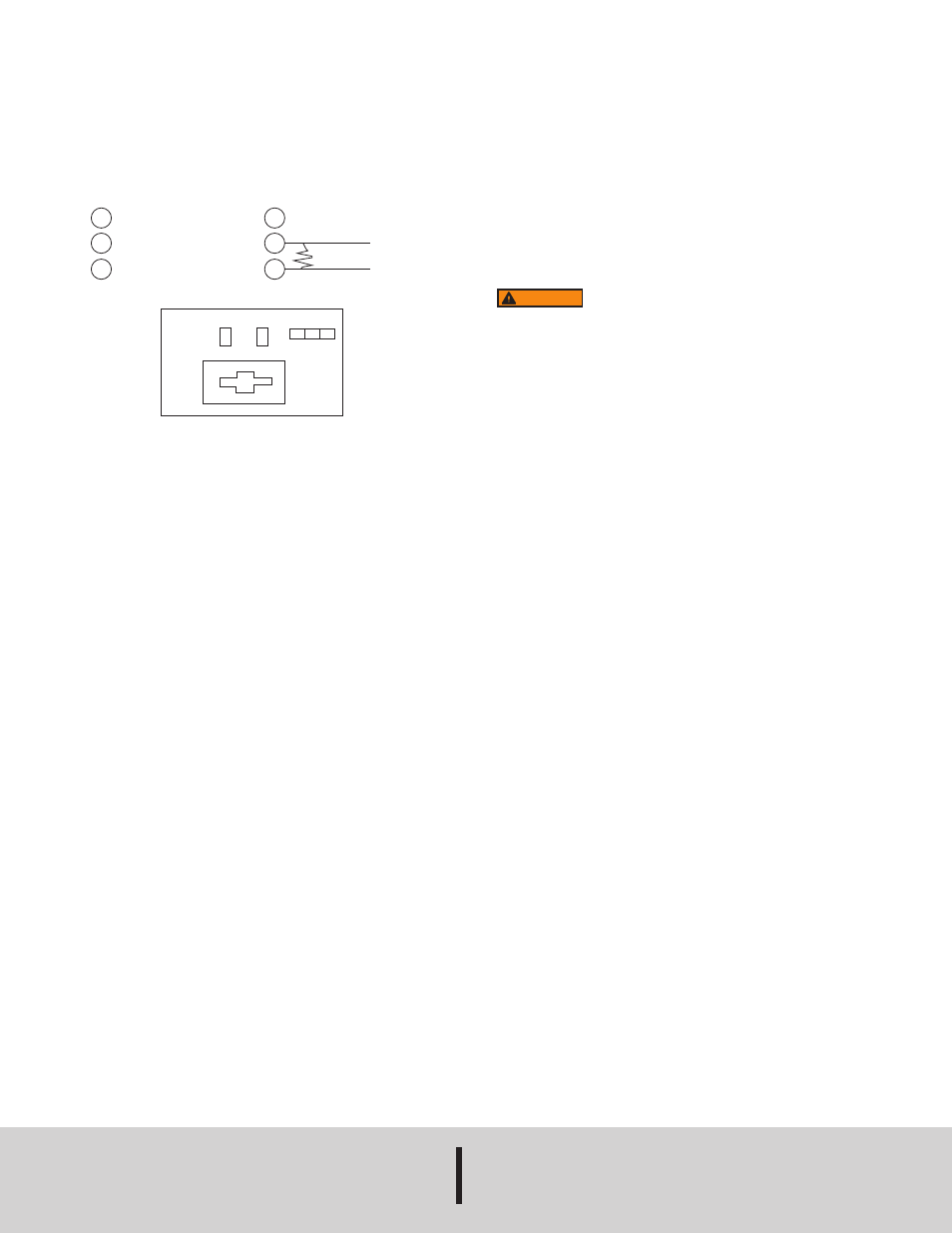

ELECTRICAL CONNECTIONS

Make all wiring connections with the power off. All circuits must be wired

to the National Electrical Code, Class 1, and in conformance with all

applicable codes and requirements with approved wiring practices. See

Figure 1 below for appropriate wiring connections

OPERATION

After applying power, allow approximately 20 to 30 minutes for

stabilization of signal.

When operating at low differential pressures of less than 5˝ w.c. or in

applications where the pressure is fluctuating rapidly – it is advisable to

insert “snubbers” for air flow restrictors in the input lines. This serves to

“steady” the output signal and keeps the signal from bouncing erratically.

ADJUSTMENTS

The Series 647 transmitters are adjusted for the specified range at the

factory and should not require further adjustments. If necessary or

desireable, the zero and span may be adjusted, however, the requested

full scale range as shipped is established with fixed resistors minimizing

the range of adjustment. The average full scale adjustment is ±10% fo

the range shipped.

“Z” – Zero Control is adjusted for 4 mA output signal at 0 psi or minimum

pressure.

“S” – Span Control is adjusted to change the full scale range of the

transmitter.

Due to resistor values required to compensate for the null off-set of the

sensing module, evidence of Zero and Span interaction may be

experienced in readjusting.

Do not adjust the bridge balance and temperature compensation

controls.

Fluid hammer and surges can destroy any pressure transducer

and must always be avoided. A pressure snubber should be

installed to eliminate the damaging hammer effects.

WARNING

Fluid hammer occurs when a liquid flow is suddenly stopped, as with

quick closing solenoid valves. Surges occur when flow is suddenly

begun, as when a pump is turned on at full power or a valve is opened

quickly.

MAINTENANCE

After final installation of the Series 647 Wet/Wet Differential Pressure

Transmitter, no routine maintenance is required. Periodic checks of

connections is recommended. Please contact Dwyer Instruments, Inc.

before returning unit for repair to review information relative to your

application. When returning a product tot he factory, carefully package

and ship freight prepaid. Be sure to include a complete description of the

application and problem and identify any hazardous material used with

the product.

ZERO

SPAN

H

L

1

2

3

1

2

3

1

2

3

24 VDC Power

4-20mA, 2-wire Loop Signal

+ 24 VDC In

4-20 mA Signal Out

No Connection

+ 24 VDC In

4-20 mA, 2-wire, Field Conversion

to 1-5 VDC Signal

1-5 VDC

Common

250 Ohms

Wiring Connections

Figure 1