Dwyer instruments, inc – Dwyer 636D User Manual

Page 2

©Copyright 2014 Dwyer Instruments, Inc.

Printed in U.S.A. 5/14

FR# R6-443317-00 Rev. 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057

e-mail: [email protected]

INSTALLATION

Care should be taken during installation to prevent condensate accumu-

lation in the conduit compartment or sediment accumulation in the

diaphragm chambers. It is good practice to install the transmitter with the

conduit connection pointing down or to utilize a conduit drain or drip leg

where this is not possible. Calibration of this transmitter is performed

with the process connections in the horizontal plane. The specified worst

case inaccuracies due to mounting orientation would occur when the

process connections are in the vertical plane. A pipe joint compound or

pipe thread sealant tape thread should be used to assure a leak-proof

process connection.

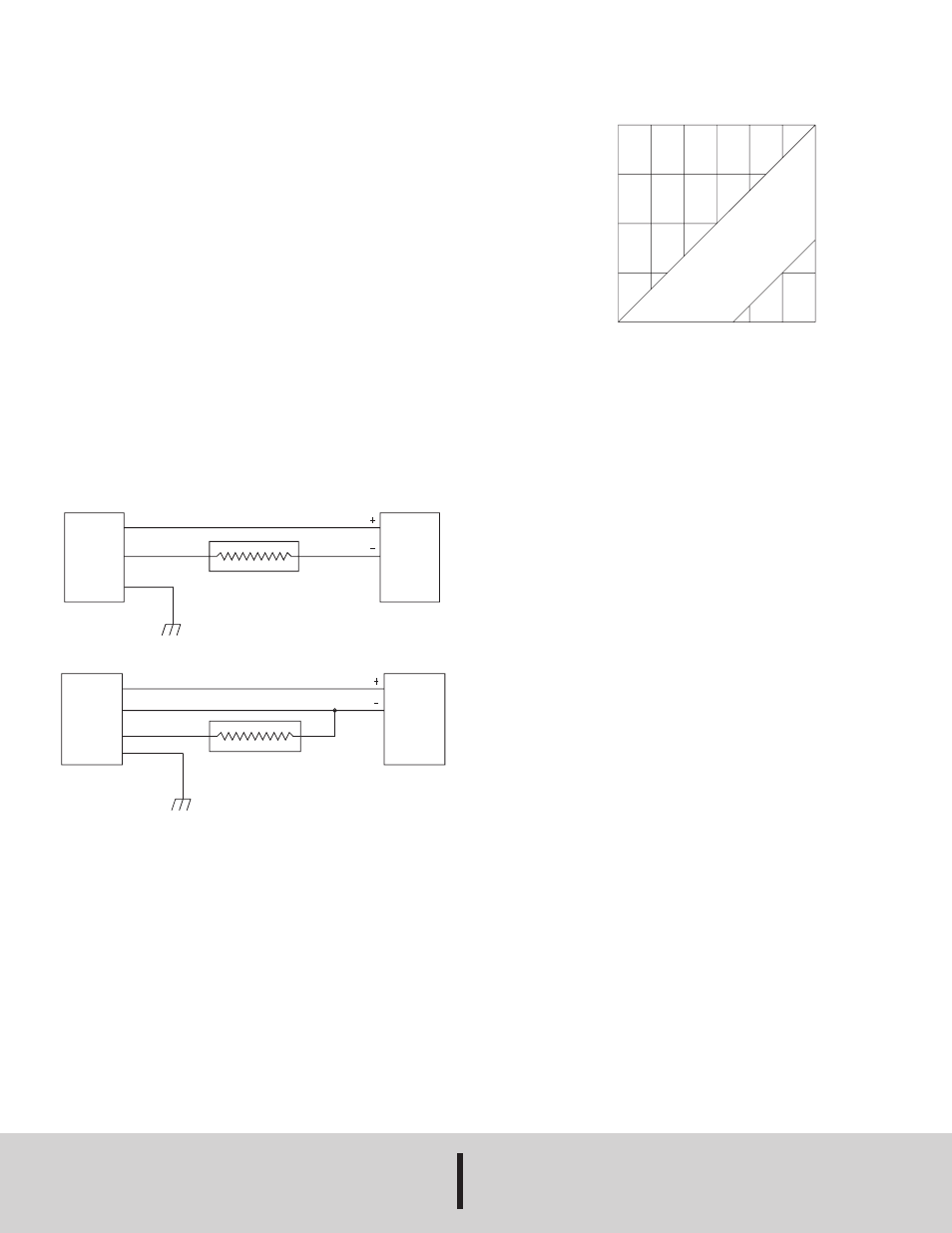

ELECTRICAL CONNECTIONS

CAUTION: Do not exceed specified supply voltage rating. Permanent

damage not covered by warranty will result. This unit is not designed for

AC line voltage operation. Power must be off while wiring connections

are being made.

An external power supply delivering 12-30 VDC with a minimum current

capability of 40 mA DC (per transmitter) or 8-14 VDC when using a 1-5

VDC output model, must be used to power the control loop. See Fig. A.

To comply with good electrical practice, it is recommended that the trans-

mitter be grounded. This can be accomplished through either the green

wire or the transmitter case. To avoid a “ground loop” condition, DO NOT

use both. The shield/drain wire is not connected to the case. This

shield/drain is normally tied to ground at the receiver for optimal noise

rejection.

The range of appropriate loop resistance, including the receiver load

resistance for the DC power supply being used is limited to that

expressed by the graph in Fig. B.

MAINTENANCE

Upon final installation of the Series 636D Fixed Range Differential

Pressure Transmitter and the companion receiver, no routine mainte-

nance is required. A periodic check of the system calibration is recom-

mended. The Series 636D Fixed Range Differential Pressure

Transmitter is not field serviceable and should be returned if repair is

needed (field repair should not be attempted and may void warranty). Be

sure to include a brief description of the problem plus any relevant appli-

cation notes. Contact customer service to receive a return goods autho-

rization number before shipping.

Fig. A

Fig. B

SERIES

636D LP

PRESSURE

TRANSMITTER

POWER

SUPPLY

12-30 VDC

RED

BLACK

WHITE

GREEN

RECEIVER

SERIES 636D

PRESSURE

TRANSMITTER

POWER

SUPPLY

12-30 VDC

RED

BLACK

GREEN

RECEIVER

900

675

450

225

0

12

15

18

21

24

27

30

SUPPLY VOLTAGE (VDC)

L

O

O

P

R

E

S

IS

T

A

N

C

E

(

O

H

M

S

)

OPERATING

RANGE

4-20 mA Output

Voltage Output