Dwyer instruments, inc – Dwyer DX User Manual

Page 2

UNPACKING

Remove the DX from the shipping carton and inspect for damage. If damage is

found, notify the carrier immediately.

INSTALLATION

Insure that the process fluid is compatible with the wetted

materials.

Do not exceed the maximum device ratings.

Insure that the system is not pressurized before installing or

removing this device or other objects from the system.

The DX is to be mounted with the pressure connections horizontal ±10°.

For pipe mounting, mount the unit from the pressure connections to the pipe. Make

sure the piping is properly supported to handle the weight of the pressure switch.

For surface mounting, mount the unit to the selected surface using the mounting

ear holes provided using two #6 or #8 screws. See the Figure 2 for mounting hole

spacing.

Make sure that connections are connected to the proper port. The high pressure

port is marked with the “+” sign and is on the left side of the unit with the label side

facing you. The low pressure port is marked by the “-“ sign and is the right side of

the unit. Piping or tubing should always be turned into the pressure port, do not turn

the pressure switch. When installing the piping or tubing into the switch always use

a wrench on the flats of the pressure connection. Use pipe thread sealant tape or

other suitable pipe joint compound when making the pressure connection.

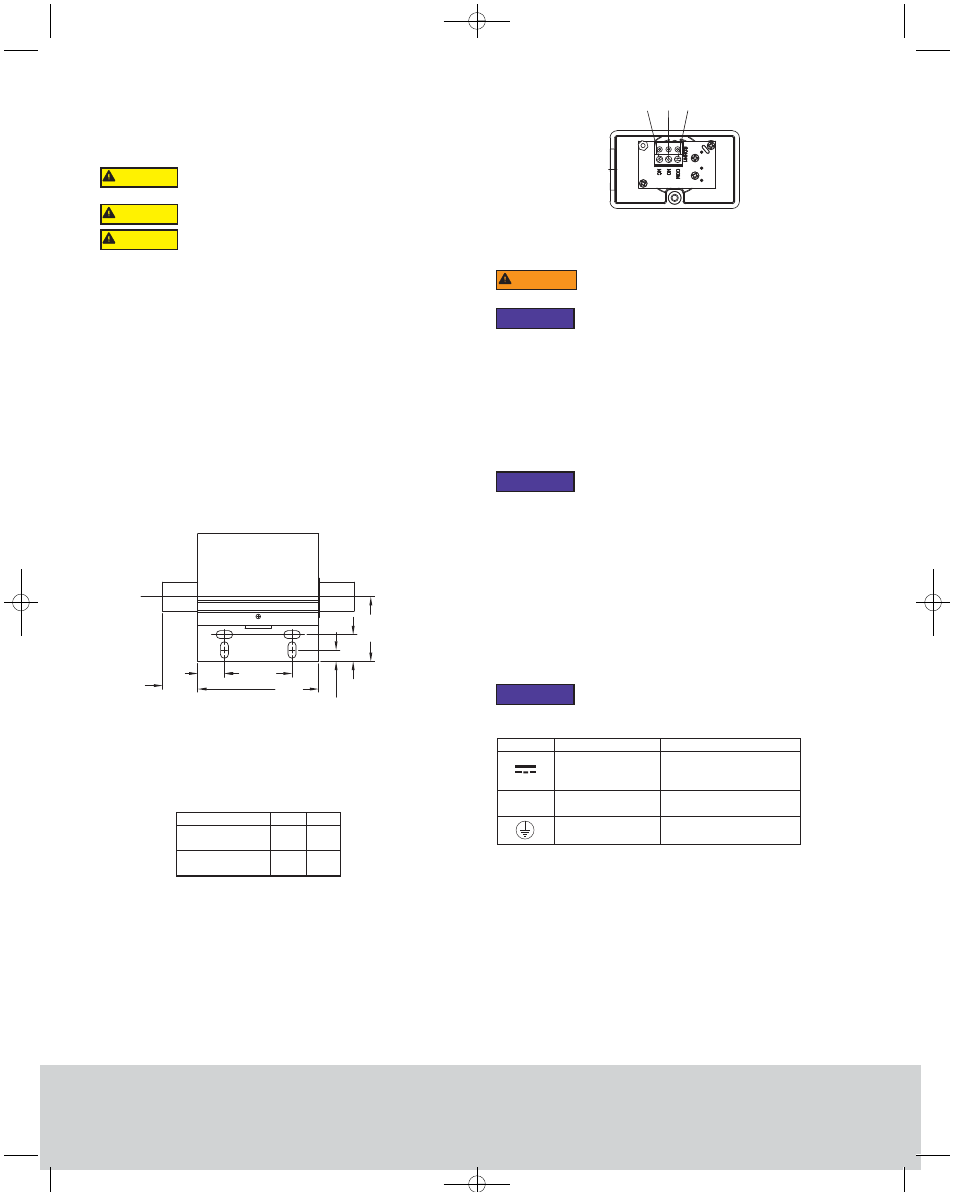

ELECTRICAL CONNECTION

A SPDT snap action switch is provided. The output logic is shown in Table 1.

Power must be off while wiring connections are being made.

Installation must be made in accordance with local codes and

regulations.

Electrical connections are made to the removable terminal block inside the

enclosure. Remove the terminal block from the circuit board for wiring if desired.

Feed stripped and tinned leads through the conduit opening and connect them as

shown in Figure 2. 250V @ 60C 14 to 24 AWG / 2.5 to .25 mm

2

wiring with PVC or

equivalent insulation with 94-V0 or FV-0 flammability rating is recommended for the

switch. Replace terminal block after wiring. The DX provides one 0.871˝ diameter

hole for 1/2˝ conduit fitting. The conduit connections must be made such that

condensation is not allowed to enter the sensor housing. If necessary install a

conduit breather drain in a separate conduit body to prevent buildup of moisture.

For weatherproof applications, install directly to conduit or use

the optional cable gland accessory.

SETPOINT ADJUSTMENT

The set point is adjusted with a standard slotted head screw driver.

1) Remove rubber plug over set point adjustment screw located on the right side of

the unit (with the label side facing you).

2) Insert the screw driver to turn the set point adjustment.

3) A clockwise rotation is an increase in differential pressure set point and a

counterclockwise rotation is a decrease in differential pressure set point. (The

set point screw can be turned too far as to fall out; do not turn the screw to the

point that there are no longer any female threads visible in the switch body).

4) Using a pressure source and pressure gauge adjust the set point screw to the

set point desired while monitoring the contact output.

5) Once desired set point is achieved replace set point adjustment cover.

Design a fail-safe system that takes into consideration the

possibility of switch failure, power failure, and operator error.

MAINTENANCE & REPAIR

Inspect and clean switch with water or damp cloth as needed. Disassembly or

modifications made by the user will void the warranty and could impair the

continued safety of the product. If repair is required obtain a Return Goods

Authorization (RGA) number and send the unit, freight prepaid, to the address

below. Please include a detailed description of the problem and conditions under

which the problem was encountered.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Indiana Hwy 212

Michigan City, IN 46360

Condition

Differential Pressure

Above Set Point

Differential Pressure

Below Set Point

NO

Closed

Open

NC

Open

Closed

Description

Direct current

Alternating current

Protective conductor terminal

Symbol

Explanation of Symbols:

~

Publication

IEC 50417 - 5031

IEC 50417 - 5032

IEC 50417 - 5019

Table 1: Switch Action

Figure 2: Wiring Diagram

NOTICE

NOTICE

NOTICE

NC

NO

COM

VIEW OF TERMINAL BLOCK

INSIDE SWITCH HOUSING

2-1/2

[63.50]

15/64

[6.00]

1-13/32

[35.56]

35/64

[13.97]

2X

47/64

[18.54]

1-11/32

[34.04]

9/16

[14.10]

Figure 2: Mounting Hole Dimensions

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

©Copyright 2010 Dwyer Instruments, Inc.

Printed in U.S.A. 10/10

FR# M3-443822-00

CAUTION

CAUTION

CAUTION

WARNING

IN-DX:SSS-1000 10/1/10 10:16 AM Page 2