Dwyer instruments, inc, Adjustment, Maintenance – Dwyer 1996 User Manual

Page 2

3. Remove the snap-on cover from the conduit

enclosure by loosening its retaining screw and pulling

firmly on its set screw held end. Electrical terminals for

all switches are marked Common, Normally Open, and

Normally Closed. The switch is not actuated until

pressure is applied. On rising pressure, the switch actu-

ates and Normally Open contacts close. Should gas

pressure fail, the switch (when set for low gas pressure)

will de-actuate and the Normally Open contacts re-open.

When set for high gas pressure (regulator failure) the

switch will actuate (and Normally Closed contacts will

open) when overpressure occurs. Wire switch accord-

ingly: make sure load doesn't exceed electrical ratings.

Use flexible or rigid conduit to enclose wires to switch.

4. Adjust the set point following instructions under

adjustment.

5. Check carefully for leaks. Be sure that switch set

point and installation complies with the furnace/burner

manufacturer’s instructions. Watch the On-Off indicator

in window to observe proper operation.

ADJUSTMENT

1. To change the set point, remove the cover from the

conduit enclosure. Turn the slotted Adjustment Screw at

the end of the range spring housing clockwise to raise

the set point pressure and counter-clockwise to lower

the set point. The visible set point indicator shows the

set point from 4 (min) to 20 (max) inches w.c. for Model

1996-20 and 1.5 (min) to 5 (max) inches w.c. for Model

1996-5.

2. (a) For high gas pressure applications, to actuate on

regulator failure, adjust the set point so that desired set-

ting (normally 1

″ or 12″ above operating pressure)

shows in the window.

(b) For low gas pressure applications, to actuate on gas

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

Lit-By Fax: 888/891-4963

Series 1996 – Natural and L.P. Gas Pressure Switches

Specifications - Installation and Operating Instructions

Bulletin E-58

Page 2

©Copyright 2000 Dwyer Instruments, Inc.

Printed in U.S.A. 6/00

FR # 26-440252-00 Rev. 1

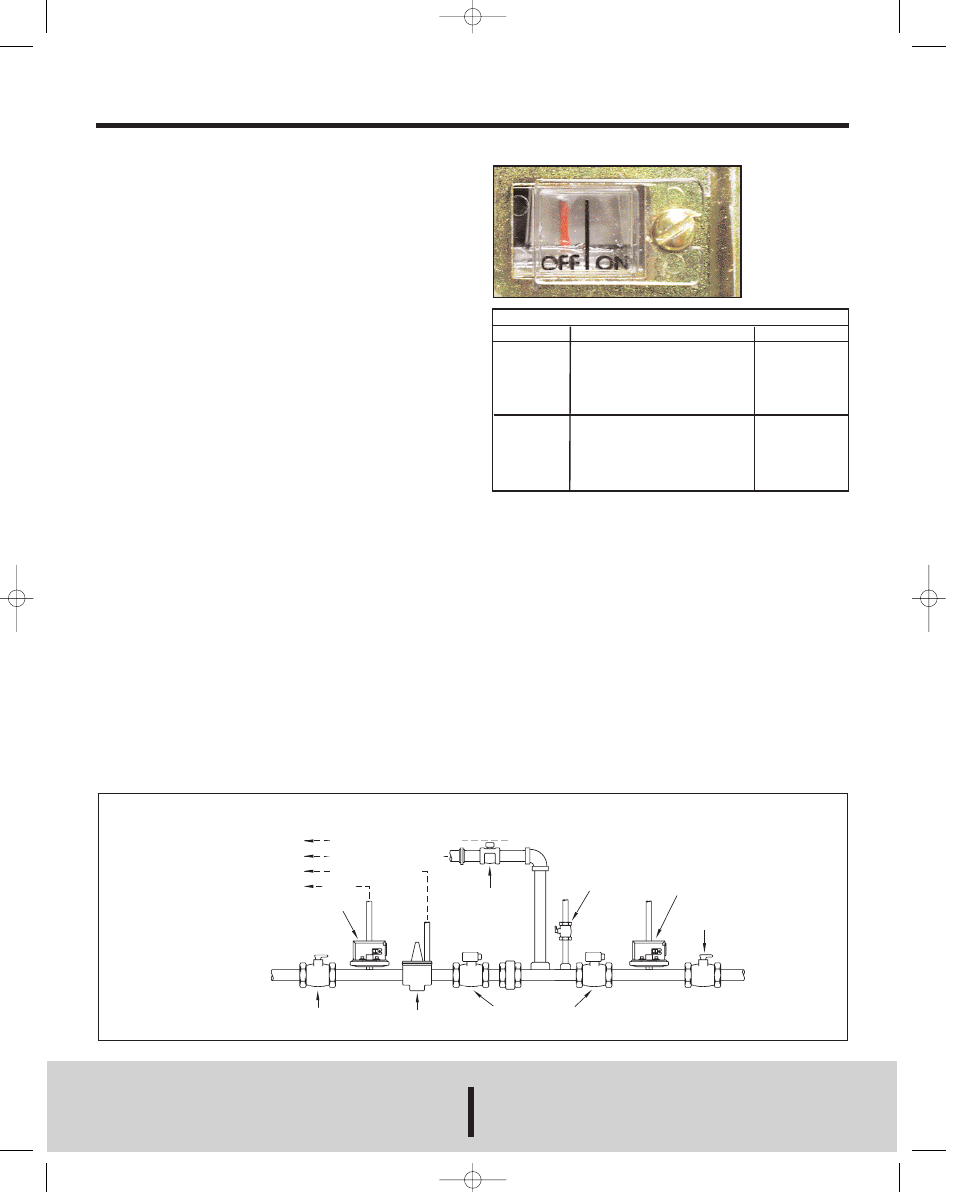

Visible on-off

pointer indi-

cates actuation

or de-actuation

of switch. This

permits instant

trouble-shoot-

ing of electrical

circuit or gas

supply.

Motorized

Gas Valves

Typical Piping Diagram for Gas-Fired Furnaces

(Pilots Not Shown)

Low Pressure

Gas Switch

Vent outside

separately or to

combustion chamer

per manufacturer's

instructions.

Gas

Supply

Main Gas

Shut-Off Valve

Gas Pressure

Regulator

Solenoid

Vent Valve

(Normally Open)

Test

Cock

High Pressure

Gas Switch

Checking

Gas Cock

To Main

Burner

Inches in Water Column

Set Point Approximate Dead Band Reset Point

Model 1996-5

1.5

0.10

1.30

2

0.12

1.88

3

0.14

2.86

4 0.17 3.83

5

0.19

4.81

Model 1996-20

4

0.15

3.85

5

0.15

4.85

10

0.24

9.76

15

0.33

14.67

20

0.41

19.59

pressure failure, adjust the set point slightly below

(usually 2

″ or 1″ w.c.) the normal gas pressure.

De-actuation will occur at set point pressure minus the

dead band. See chart below.

MAINTENANCE

The moving parts of these switches are sealed in and are

permanently tamper-proof. The single adjustment is that

of the set point. Care should be taken to keep the switch

reasonably dry and free from dust or dirt. No lubrication

or unusual precautions are required for

normal use.

new E-58 REV 1 6/24/02 8:47 AM Page 2