Caution – Blue-White CHEM-PRO C3 ProSeries Diaphragm Pump User Manual

Page 7

Page 6

4.1

Mounting Location

Choose an area located near chemical supply tank, chemical injection point, and electrical supply. Install pump

where it can be easily serviced.

316SS Mounting brackets are included. Mount pump to a secure surface using enclosed mounting hardware.

Mount pump close to injection point. Keep inlet (suction) and outlet (discharge) tubing as short as possible.

Longer discharge tubing increases back pressure at pump head.

Important! Install a back flow prevention check valve at discharge side of pump to prevent system fluid from

flowing back through pump during pump maintenance. Important!

A pressure relief valve is recommended at discharge of pump.

4.2

Dimensions

All diagrams are strictly for guideline purposes only. Always consult an expert before

installing metering pump on specialized systems. Metering pump should be serviced by

qualified persons only.

!

Always wear protective clothing, face shield, safety glasses and gloves when working on or

near your metering pump. Additional precautions should be taken depending on solution

being pumped. Refer to MSDS precautions from your solution supplier.

Risk of chemical overdose. Be certain pump does not overdose chemical during backwash

and periods of no flow in circulation system.

CAUTION

!

CAUTION

!

CAUTION

Page 7

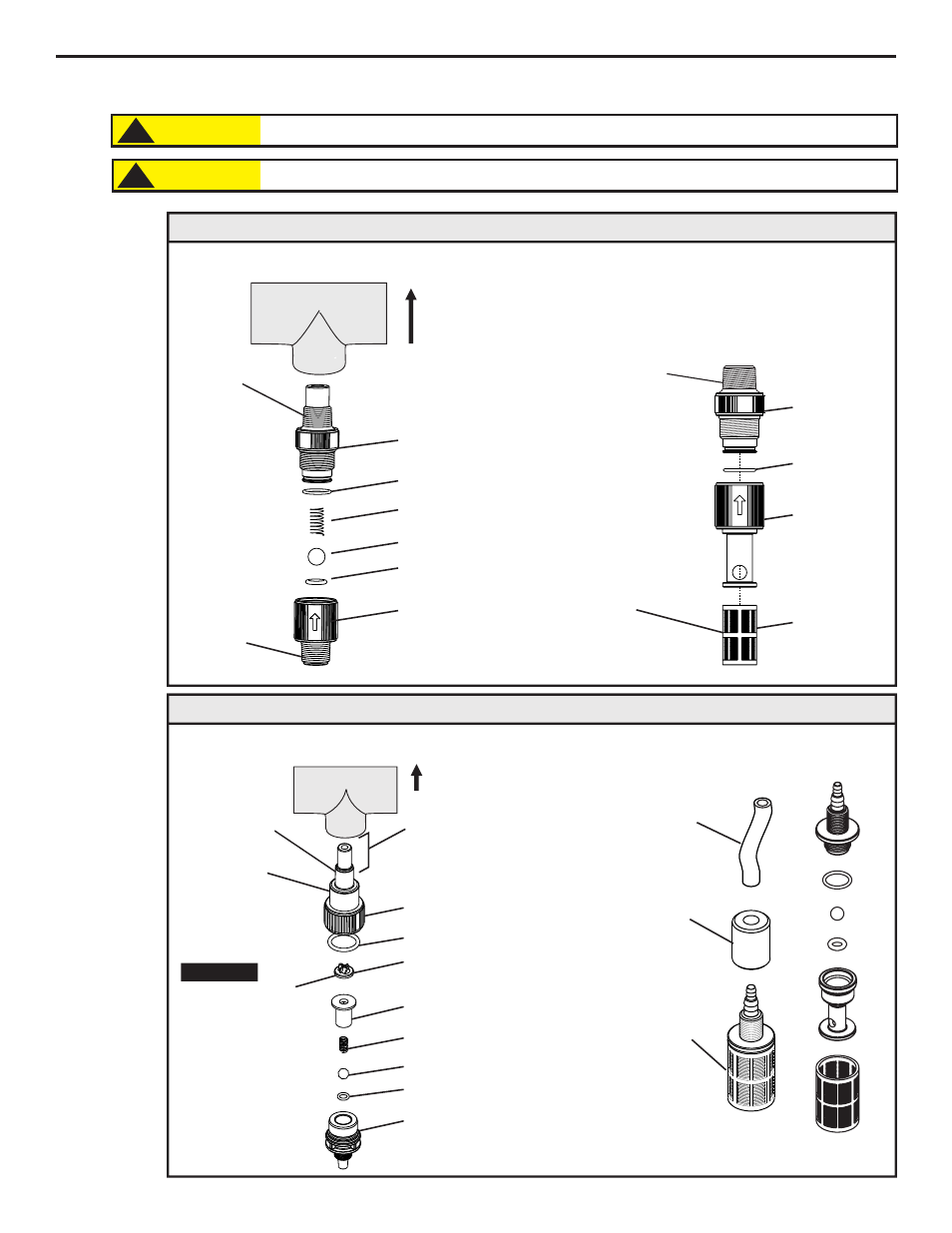

Pipe

Tee

½” male NPT

1/4” male NPT

Discharge Injection Fitting / Check Valve

Discharge Injection Fitting / Check Valve)

Pipe

Tee

Install

upward

for best

results

½” (1.3 cm)

Male NPT

½” (1.3 cm)

Male NPT

or

½” (1.3 cm)

Hose Barb

Suction Strainer

½” (1.3cm) I.D. Wetted Connection Models; Injection Fitting and Strainer

Suction Tubing and Strainer

Suction Tubing, PVC

3/8" (.95 cm) OD X

1/4” (.64 cm) ID

Duckbill - May reduce

calcium buildup when

injecting bleach.

Duckbill will add

additional back

pressure to pump (up

to 7 psi / .48 bar).

Remove duckbill to

reduce pressure or

when metering viscous

fluids.

Proper eye and skin protection must be worn when installing and servicing pump.

!

CAUTION

This Pump Has Been Evaluated for Use with Water Only.

!

CAUTION

PVDF

PVDF

O-Ring, Viton (optional EP)

O-Ring, T/FEP

(optional EP)

Spring, Hastelloy C-276

Ball, Ceramic

½” (1.3 cm)

Male NPT

or

½” (1.3cm)

Hose Barb

PVDF

PVDF

O-Ring, Viton

(optional EP)

Polypropylene

Removable

275 Micron

Filter

PVDF

Spring, Hastelloy C-276

PVDF

O-Ring, T/FEP (optional EP)

Ball, Ceramic

O-Ring, Viton (optional EP)

Duckbill, Santoprene

(optional)

PVDF

Injection Nose

may be trimmed

(removed) when

injecting into

small pipe.

Install upward

for best results

Note:

Optional Extended Bracket adds 4.5” (11.43cm) to overall height (dimension G and H). See page 3 for details.

1/4” (.64cm) I.D. Tube Wetted Connection Models; Injection Fitting and Strainer

4.0

Installation

4.3

Installing Injection Fitting and Strainer

Important!

Chem-Pro

Chem-Pro

®

®

Top

Front

Right

A

B

C

D

E

G

H

I

F

J

Inches

cm

A

B

C

D

E

12.8”

11.5”

3.7”

2.5”

11.8”

32.5

29.2

9.5

6.4

29.9

C2 Dimensions

F

7.9”

20.1

G

H

I

J

7.3”

18.4

6.5”

16.4

13.6”

34.6

8”

20.3

Dim

Inches

cm

A

B

C

D

E

14.1”

12”

3.7”

2.5”

13.1”

35.8

30.5

9.5

6.4

33.2

C3 Dimensions

F

9”

22.9

G

H

I

J

7.8”

19.8

6.5”

16.4

15”

38

8”

20.3

Dim

FootValve

Strainer

Assembly

Ceramic

Weight