Installation, 1 installation requirements – KROHNE BM 500 EN User Manual

Page 11

INSTALLATION

3

11

BM 500

www.krohne.com

12/2013 - 4003176301 - MA BM 500 R02 en

3.1 Installation requirements

• Be sure that the measuring rod has the correct depth of immersion when placing your order.

The sensor cannot

cannot

cannot

cannot be shortened subsequently!

• Use only the recommended sleeves or adapters. If other systems are used, no guarantee can

be given for proper functioning or leak-tightness.

• The connection thread must have electrical contact with the metal vessel. If this is not

possible, use a separate grounding cable to meet this condition.

• Do not use Teflon or paper gaskets.

• The tightening torque for the sleeve should be 20...30 Nm.

• If the vessel is electrically non-conductive (e.g. plastic tank), the frame potential can be

established via an additional ground electrode, which is electrically connected to the

connection thread. E.g. a standard LS 7200 without electronics. Consult your local contact for

ordering assistance.

• Make absolutely sure that the measuring rod cannot come into contact with the wall of the

vessel. Also take into consideration the possibility of rod deflection caused by moving

product.

• For distances of less than 100 mm / 3.9" (e.g. when installed in vertical pipe runs) the sensor

rod should be located parallel to the wall, otherwise conditions of non-linearity can occur.

For large distances non-parallelity of the rods can be allowed.

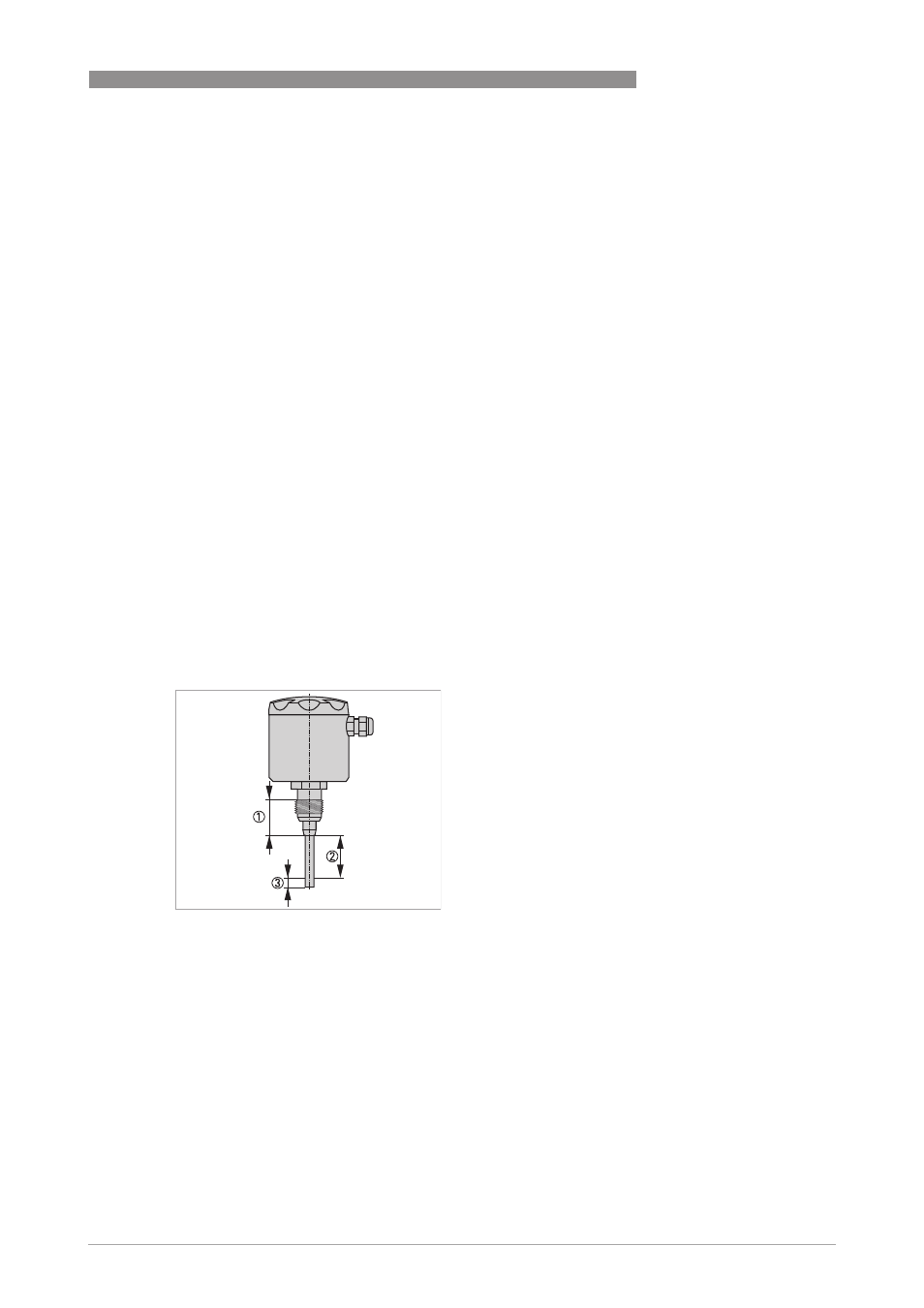

• The level meter measures linearly over the full rod length.

Lower dead zone:

Lower dead zone:

Lower dead zone:

Lower dead zone: approx. 8 mm / 0.3" of the lower end of the measuring rod

Upper dead zone:

Upper dead zone:

Upper dead zone:

Upper dead zone: approx. 44 mm / 1.73" of the upper end of the measuring rod (at the lower

end of the conical part of the rod)

Figure 3-1: Upper and lower dead zone at measuring rod

1 Upper dead zone: approx. 44 mm / 1.73"

2 Active measuring range

3 Lower dead zone: approx. 8 mm / 0.3" immerged in the liquid