KROHNE OPTIMASS Sensors Corrosion guidelines EN User Manual

Page 5

Corrosion Guide Rev 1.05 Jan 2006

5

Remember in all cases KROHNE cannot accept

responsibility for the final choice of material. The ulti-

mate responsibility lies with the end user. We can only

advise based on our experience!

Explanation of data tables

1.

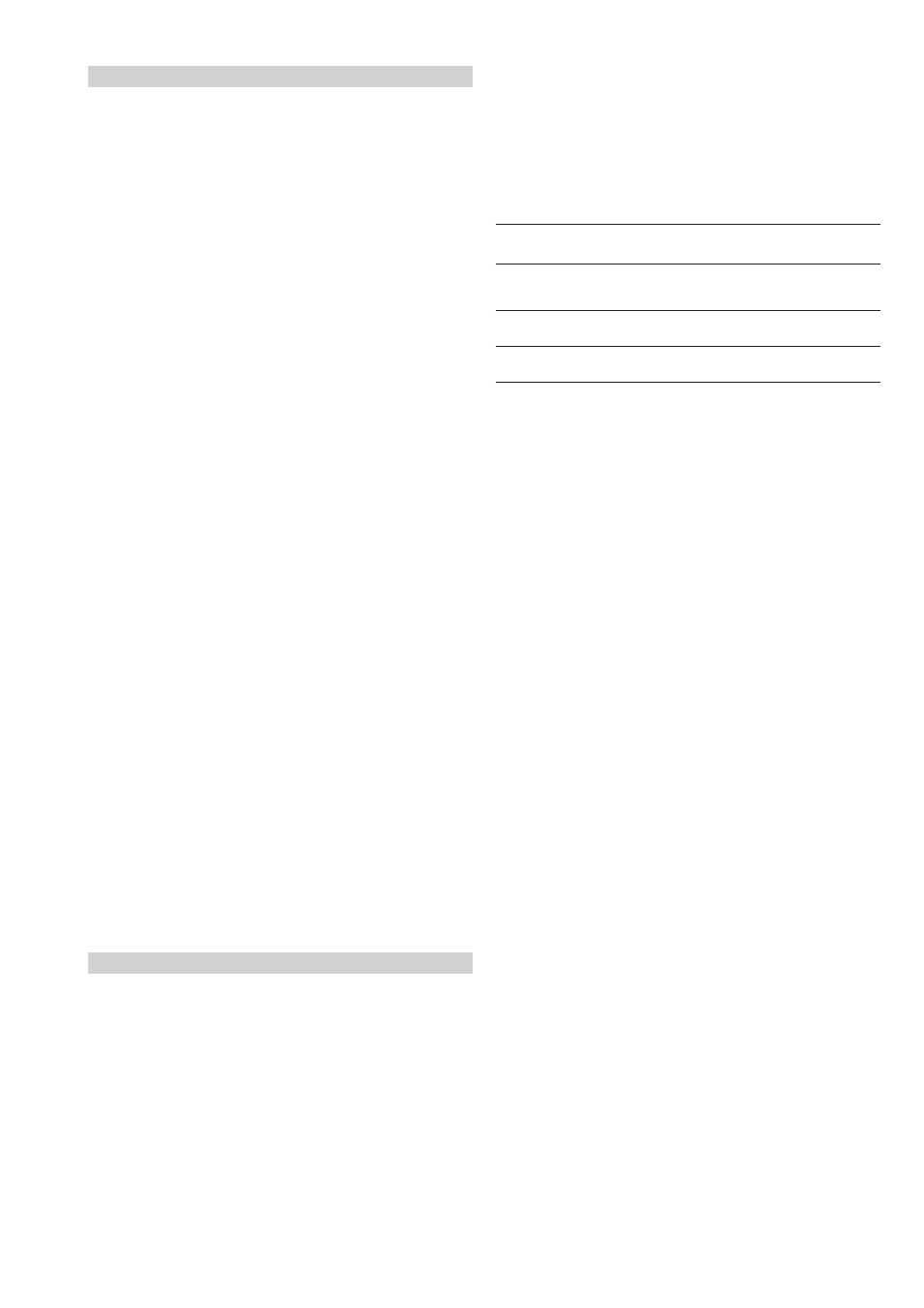

Key to symbols used

Symbol

Meaning

Suitable, with a corrosion rate less than

0.05 mm (0.002”) per year

X

Unsuitable, due to higher corrosion rate

nd

No data is currently available

1.6 Problem Applications

Hydrochloric acid (HCl):

This acid normally contains fluoride and chloride impu-

rities that will promote stress corrosion cracking in all

tube materials. This effect will always cause a meter

failure even if there is no bulk removal of tube material.

For this reason we do not recommend Optimass

meters for any HCl application.

Instead look to alternative instrument technologies such

as capacitive MID (Capaflux) or variable area flowme-

ters (H250 PTFE).

Methanol:

“Pure” methanol (> 98% purity) tends to cause the

removal of the protective oxide layer on a titanium

measuring tube thus promoting corrosion. Titanium

therefore cannot be used. Stainless steel or Hastelloy

C-22 are suitable alternatives for these applications.

Methanol with a minimum 2%, or greater, water content

does not exhibit this tendency and can be freely used

with all tube materials.

Oxygen gas:

There is a risk of ignition where an oxygen rich (> 35%

O

2

) gas mixture is used with a titanium measuring

tube.Always offer stainless steel as an

alternative.Remember also that the “degreasing” option

for wetted parts should also be offered for use with oxy-

gen gas applications.

Passivation of meters

A “passivation fluid” is normally composed of a mixture

of nitric acid (HNO

3

) and hydrofluoric acid (HF) and is

used to ‘passivate’ (clean) stainless steel pipework in

high purity systems, typically found in the pharmaceuti-

cal industry. The process removes weld discoloration,

dirt, grease, metal particles, etc.

The nitric acid has negligible corrosive effect, but

hydrofluoric acid is very aggressive even at levels less

than 0.5% for all wetted tube materials. It is recom-

mended that any meter is removed and replaced with

spool pieces during the passivation process. This is

due to the relatively thin wall of mass flow meter tubes;

the customer’s pipework being relatively thick is toler-

ant to a small loss of material.

1.7 Using Material Compatibility Tables.

Identify the chemical to be used either by name or by

the Formula.

Check that you know the concentration of the chemical

and that it is within the concentrations listed in column

3.

Identify the best material for the application and then

check that this is acceptable for the customer.

2.

Where a temperature is given, this signifies suit-

ability only up to this point (e.g. 212/100 denotes

up to 212

o

F or 100

o

C). Where no temperature is

given, this signifies suitability up to the lower of

either the boiling point of the product, or the

maximum operating temperature of the Optimass

flowmeter concerned.

The first temperature given is always in Fahrenheit

and the second in Centigrade/Celsius.

3.

Always check the relevant technical data sheet

for the maximum operating temperature of the

meter series and wetted material.

4.

For the purposes of corrosion resistance, stain-

less steel grades 316L and 318L can be consid-

ered as both being the same.