KROHNE OPTIMASS Sensors Corrosion guidelines EN User Manual

Page 4

4

Corrosion Guide Rev 1.05 Jan 2006

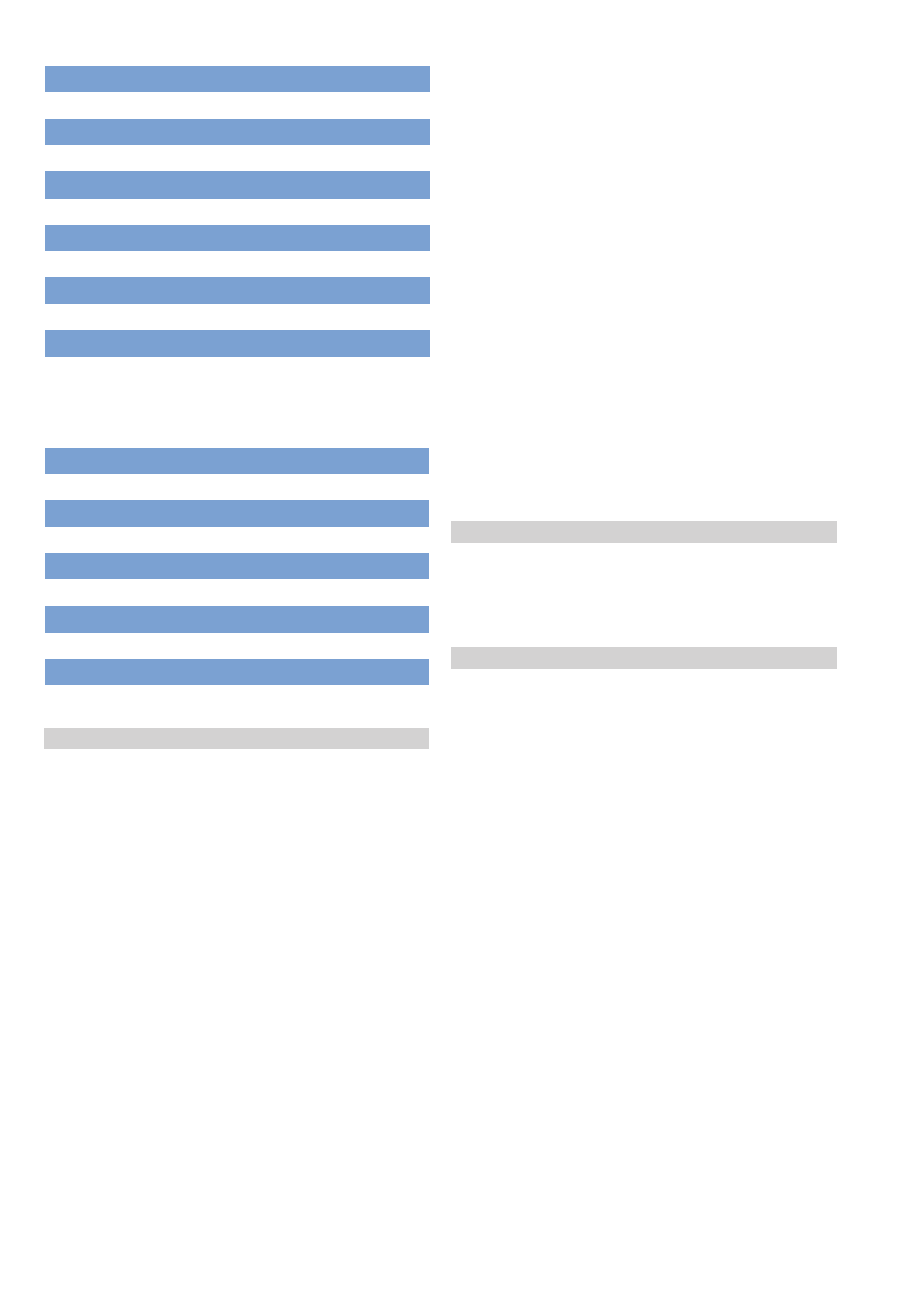

Element

Typical

Specification

C

0.02

0.030 Max

Mn

0.70

2.0 Max

P

0.025

0.030 Max

S

0.001

0.020 Max

Si

0.40

1.0 Max

Cr

22.4

21.0...23.0

Ni

5.8

4.5...6.5

Mo

3.3

2.5...3.5

N

0.16

0.08...0.2

Fe

Balance

Balance

Specifications for SS318L

Element

Typical

Specification

Cr

21.6

20.00...22.5

Mo

13.7

12.5...14.5

W

2.9

2.5...3.5

Fe

4.7

2.0...6.0

Co

1.1

2.5 Max

Mn

0.3

0.5 Max

V

0.13

0.35 Max

Ni

Balance

Balance

Specifications for Hasteloy C22

Please be aware that 318L is a “shorthand” expression

KRONHE have adopted for the material to aid our cus-

tomers’ understanding that the material is a low carbon

stainless steel of a speciifc composition, in the same

way that 316L is used as “shorthand” for UNS S31603.

318L is more expensive to use than 316L, but we need

to consider the technical benefits that it brings. 318L

has a much higher tensile strength compared to 316L.

We use this property in our meter to manage the stress

caused by lengthening of the tube under thermal

expansion. If we used 316L, the tube would deform

well below the +100

0

C maximum we specify for 318L.

The corrosion resistance of 318L is equal to 316L. The

standard surface roughness is similar and it can be pol-

ished to the same fine surface finish of <0.5 um Ra for

hygienic and aseptic applications. 318L is extensively

used worldwide, where customers utilise the higher ten-

sile strength to reduce wall thickness (and so the cost

and weight) of process plant and piping. This means that

there should be no reluctance from our customers in

accepting this material.

KROHNE is the only company to offer a stainless steel

straight tube mass flowmeter.

1.4 NACE Information

National Association of Chemical Engineers (NACE stan-

dard MR0175-2000) is a material requirements standard

relating to the general problems of Sulphide Stress

Cracking (SSC) of metals directed towards sour environ-

ments.

1.5 Galvanic Corrosion with Titanium

This can occur when a titanium tube meter is placed in

contact with other metals, for instance in a steel

pipeline. As titanium is a “noble” metal, the other mate-

rial will normally corrode in preference to the titanium.

In the case of stainless steel pipelines, titanium is very

close in the galvanic table therefore galvanic corrosion

is unlikely to be a problem and no precautions are nec-

essary.

If carbon steel pipelines are used, galvanic corrosion of

the carbon steel may occur with certain acids. This cor-

rosion process causes small amounts of hydrogen gas

to be liberated at the wetted metal-to-metal contact

area. This hydrogen gas may then cause embrittlement

in the titanium. This can be avoided by electrically insu-

lating the Optimass from the pipeline using insulating

gaskets, bolt sleeves and washers.

Of course the use of an alternative tube material e.g.

Hastelloy C-22 will prevent the problem entirely.

1.3.1 What is 318L Stainless steel?

Many customers have asked “what is the 318L stainless

steel that you use in the Optimass 7000 single straight

tube meter, and why do you use this material instead of

316L”? Measuring instruments are more normally manu-

factured with wetted parts from 316L stainless steel,

which is a 100% austenic structure steel, with composi-

tion 18% .Chrome, 8% Nickel, 2.5% Molybdenum, with

the balance Iron.

318L is a 50% austenitic / 50% ferritic structure steel

(typically known as "duplex"), with (typical) composition

22% Chrome, 5% Nickel, 3% Molybdenum, with the bal-

ance Iron.

This material is defined under the following internation-

al codes:

•

UNS S31803

•

ASTM A789, A790, A479, A420

•

DIN 1.4462