KROHNE OPTIMASS Sensors Corrosion guidelines EN User Manual

Page 3

Corrosion Guide Rev 1.05 Jan 2006

3

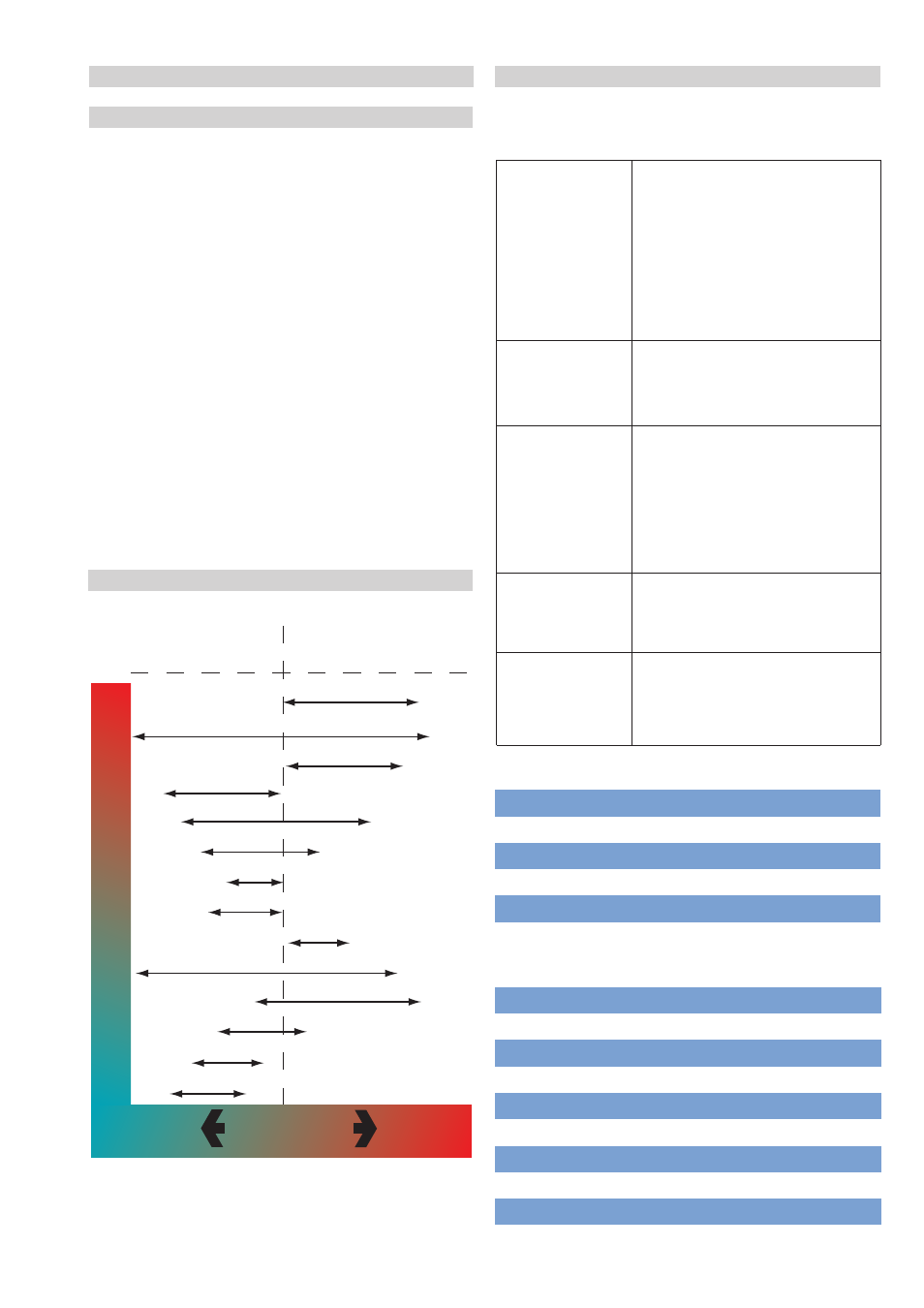

Oxidizing

Acids

Reducing

Agents

Non Chlorides

Chlorides

304 Stainless

Monel

Ni-Cr-Mo Alloy

C-4

C-276

C-22

Titanium

Ni-Mo Alloy

Zirconium

Tantalum

316 Stainless

Inconel

Monel

No 20 Alloy (Stainless)

Increasing

aggressivness

Oxidising

environment

Reducing

environment

Element

Typical

Specification

C

0.013

0.035 Max

Mn

1.6

2.0 Max

P

0.028

0.045 Max

S

0.009

0.030 Max

Si

0.38

1.0 Max

Cr

16.84

16.0...18.0

Ni

11.26

10.0...15.0

Mo

2.12

2.0...3.0

Fe

Balance

Balance

Specifications for SS316L

Element

Typical

Specification

Al

3.0

2.5...3.5

V

2.5

2.0...3.0

Fe

0.13

0.25 Max

C

0.05

0.08 Max

Ti

Balance

Balance

Specifications for Titanium Gr9

Stainless Steel

318L

7000 series

All wetted parts: UNS S31803 to

ASTM A789, A790, A479 and A240

(also known as DUPLEX Stainless

Steel SAF2205).

This 318L stainless steel is NACE

approved.

ALL hygienic and aseptic process

connections: 316L UNS 31603 or

equivalent (also NACE approved).

Hastelloy C22

7000 series

All wetted parts: UNS NO6022 to

ASTM B619, B622, B626, B574

and B575

This HC-22 is NACE approved.

Titanium

7000 series

Measuring tube: UNS R56320 to

ASTM B338 titanium grade 9

Flange raised faces: UNS R50400

to ASTM B348 and B265 titanium

grade 2.

Titanium grade 9 is not NACE

approved.

Stainless Steel

316L

3000, 8000 / 9000

series

All wetted parts: 316L UNS 31603

or equivalent.

316L is NACE Approved.

Hastelloy C22

3000, 8000 / 9000

series

All wetted parts: UNS NO6022 to

ASTM B622, B626, B564, B574

and B575.

Hastelloy C22 is NACE approved.

1. Corrosion Of Wetted Parts

1.1 Introduction:

General corrosion guidelines for process vessels,

pipework and parts (such as thermo-wells or MID

flowmeter earthing rings) cannot be applied to Coriolis

mass flowmeters, since they refer to the bulk removal

of material from comparatively thick walled compo-

nents, and they also tend not to address specific

localised corrosion mechanisms.

Greater care must be taken in the case of mass

flowmeters, since the tube wall thicknesses are in the

region of 0.2 … 2mm (depending on meter size), so

the removal of even a small amount of material can

cause a measurement problem or a meter tube

mechanical failure.

Additionally, localised corrosion effects such as pitting

or stress corrosion cracking can occur even without

corrosion of the overall tube. If severe enough, these

effects may cause a meter tube mechanical failure.

For these reasons you will find that many fluids will be

shown as unsuitable in this guide for use with mass

flowmeters when compared to more general corrosion

guidelines.

1.2 Material Compatibility

1.3 Material information

The Optimass meter range can be supplied with wet-

ted parts (measuring tubes and connections) in the fol-

lowing materials: