Operation, 2 troubleshooting – KROHNE SMARTSENS PH 1590 EN User Manual

Page 22

4

OPERATION

22

SMARTSENS PH 1590

www.krohne.com

11/2013 - 4002545902 - MA SMARTSENS PH 1590 R02 en

• Press Ok

Ok

Ok

Ok to proceed.

• The message No saving possible

No saving possible

No saving possible

No saving possible appears.

• Press Ok

Ok

Ok

Ok to proceed.

• Select no

no

no

no to deactivate the function manual hold

manual hold

manual hold

manual hold.

• Press Next

Next

Next

Next to leave the calibration menu.

In a fully functional sensor, the optimal slope is -59 mV for each pH unit and the optimal zero

point is 0 mV at pH 7. The slope should at least have a value between -50...-65 mV per pH unit.

Re-calibrate the sensor if the slope does not approximate those limits. The pH sensor ages, the

slope gets flatter and the zero error increases.

4.2 Troubleshooting

CAUTION!

•

Never touch or scratch the pH sensitive glass tip of the sensor.

•

Make sure that the sensor tip is clean and dust-free. If necessary, clean the tip as described

on page 24.

CAUTION!

Moisture inside the sensor connector must be avoided! Moisture may cause a shortcut and

deliver erratic readings!

If moisture has entered the connector dry it with air (e.g. hair blower).

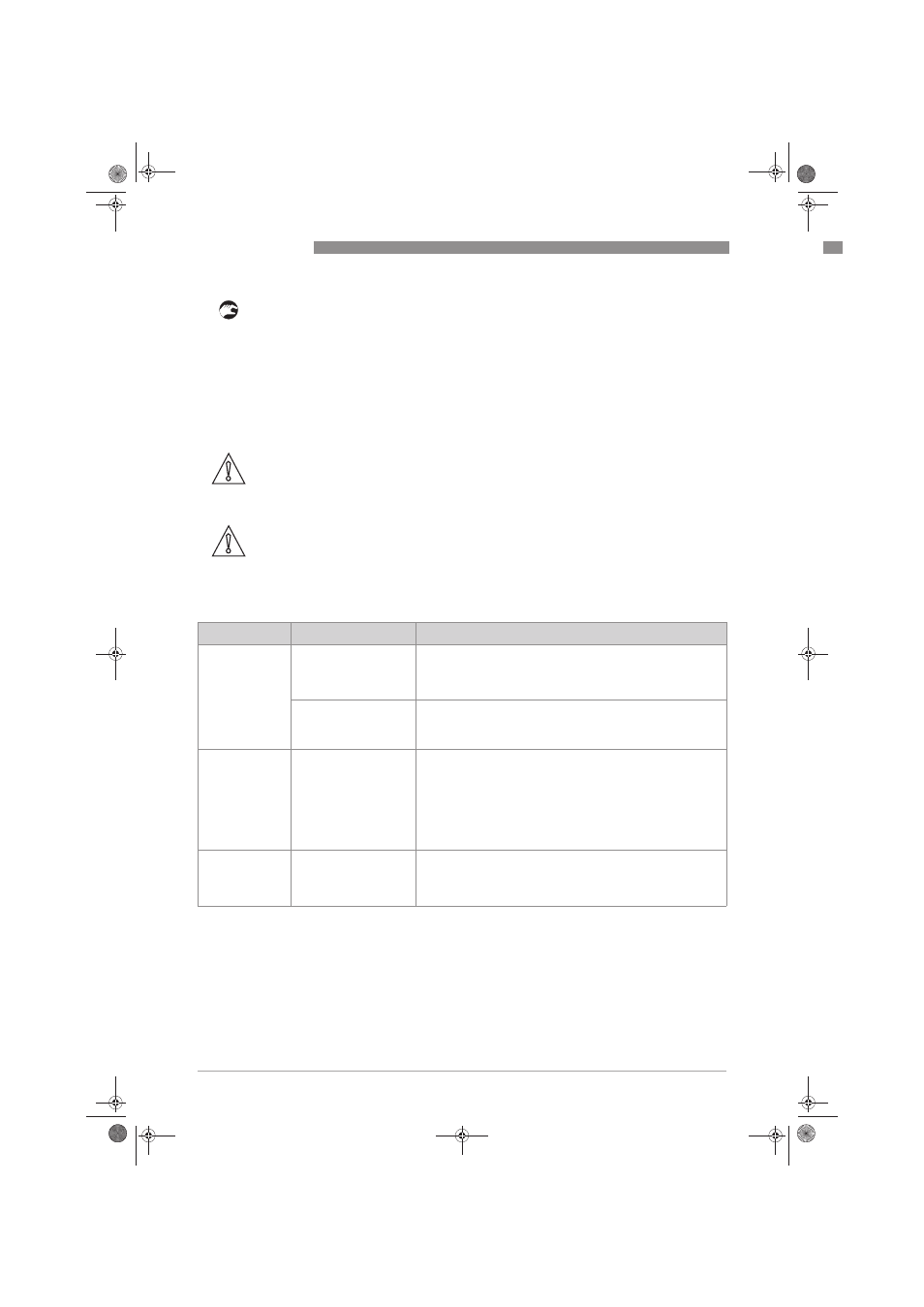

Problem

Possible cause

Remedy

The pH sensor

does not deliver a

signal.

Mechanical damage of the

glass, e.g. small cracks.

This will shortcut the ion

exchange and deliver a pH

7 reading.

Exchange sensor.

Open circuit

Check the cable wiring of the sensor cable on the junction box.

Otherwise connect the sensor to the primary master e.g.

PACTware

TM

FTD/DTM or to the HART

®

handheld to exclude a sensor

damage.

The pH sensor

delivers an

unstable signal.

The diaphragm in the

reference half cell does

not provide good contact

to the process medium

due to drying up or

coatings.

•

Clean the diaphragm with hot soap or acid using a soft tissue

(details on page 24).

•

Submerge sensor in water and increase the temperature to

+50...+60°C / +122...+140°F.

•

Submerge sensor in 3 molar KCl solution at ambient temperature.

The decrease in temperature will cause the reference half cell to

suck in KCl solution through the diaphragm and regenerate the

diaphragms functionality.

High pH value

Air bubble in the sensor

tip (no inner buffer

solution)

Protect the sensor tip with a protection cap as descriped on page 12.

Hold the sensor into a vertical position and help by rapid movements

of the wrist to shake the liquid down. Remove the protection cap and

check if there is still an air bubble inside the sensor tip. If necessary,

repeat this procedure one more time.

.book Page 22 Wednesday, October 30, 2013 11:35 AM