Installation – KROHNE BM 26 BASIC_ADVANCED Quickstart EN User Manual

Page 6

2

INSTALLATION

6

BM 26 BASIC/ADVANCED

www.krohne.com

10/2012 - 4000346904 - QS BM 26 Basic-Adv R04 en

How to remove the float lock pin (devices with side process connections)

1 Check the measuring chamber for a red sticker next to the bottom side process connection.

i

Sticker text: ATTENTION! Take away transport safety device for float.

2 Remove the adhesive tape around the top and bottom process connections.

3 Remove the plastic protection from the top and bottom process connections.

4 Find the lock pin.

5 Remove the lock pin with a pair of pliers.

How to put the float in the measuring chamber (if it is delivered separately)

• Remove the bottom blind flange or plug (if the basic version has the 1¼¨ drain option).

• Put the top of the float (the float data is on the top part of the float) in the measuring chamber

first.

• Align the gaskets.

• Tighten the nuts on the blind flange to the correct torque (11 Nm in operating conditions,

23.5 Nm in test conditions). The 1¼¨ plug must be tightened in agreement with good

engineering practice.

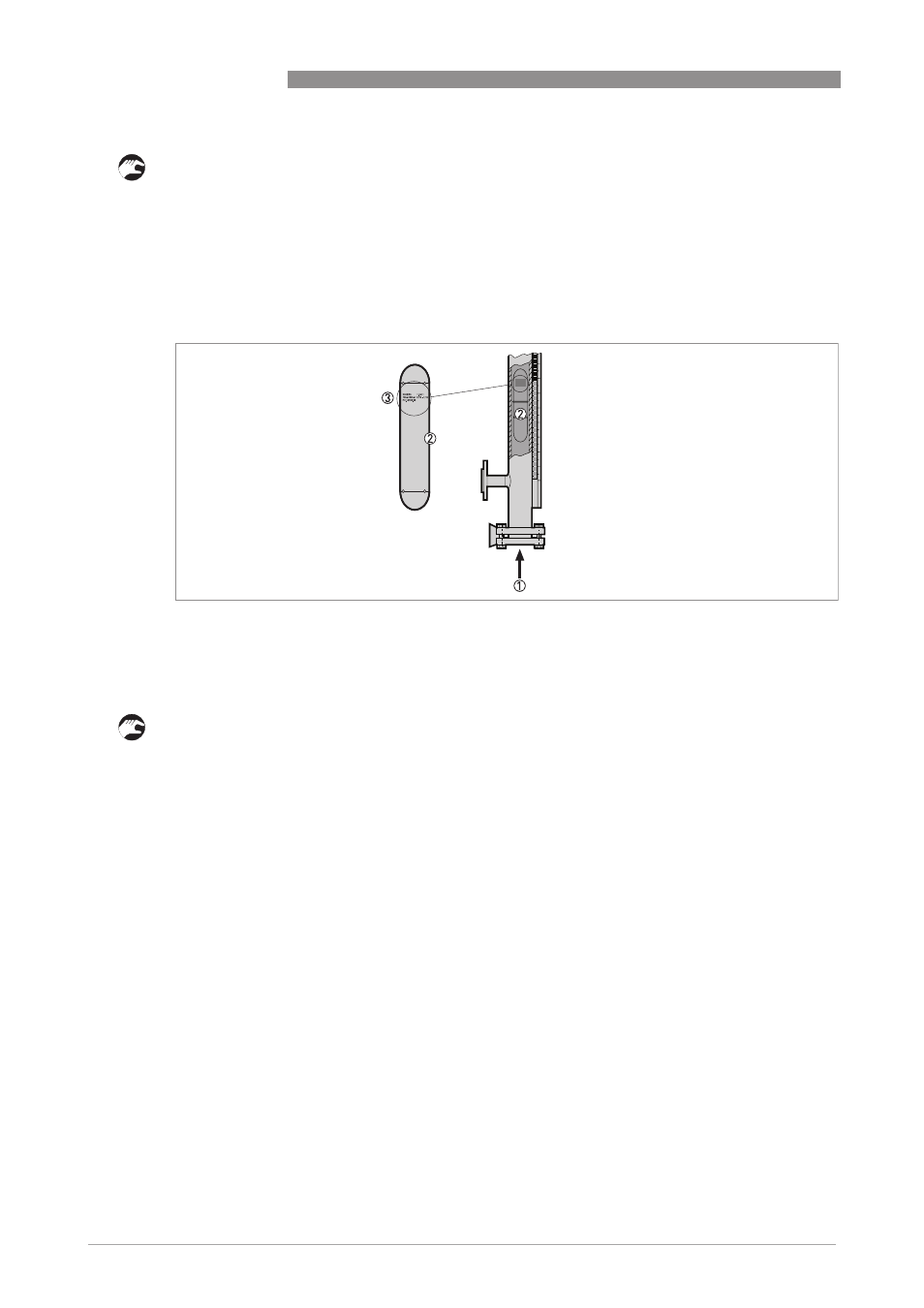

How to put the float in the measuring chamber

Figure 2-4: How to put the float in the measuring chamber (if it is delivered separately)

1 Put the float in here

2 Float

3 The float data (date of manufacture, P

s

/P

t

, float material etc.) must be at the top of the float when you put the float in

the measuring chamber