Installation, 2 installation of weld-on versions – KROHNE OPTIFLUX 6000 Quickstart EN User Manual

Page 14

2

INSTALLATION

14

OPTIFLUX 6000

www.krohne.com

07/2013 - 4002945701 - QS OPTIFLUX 6000 R05 en

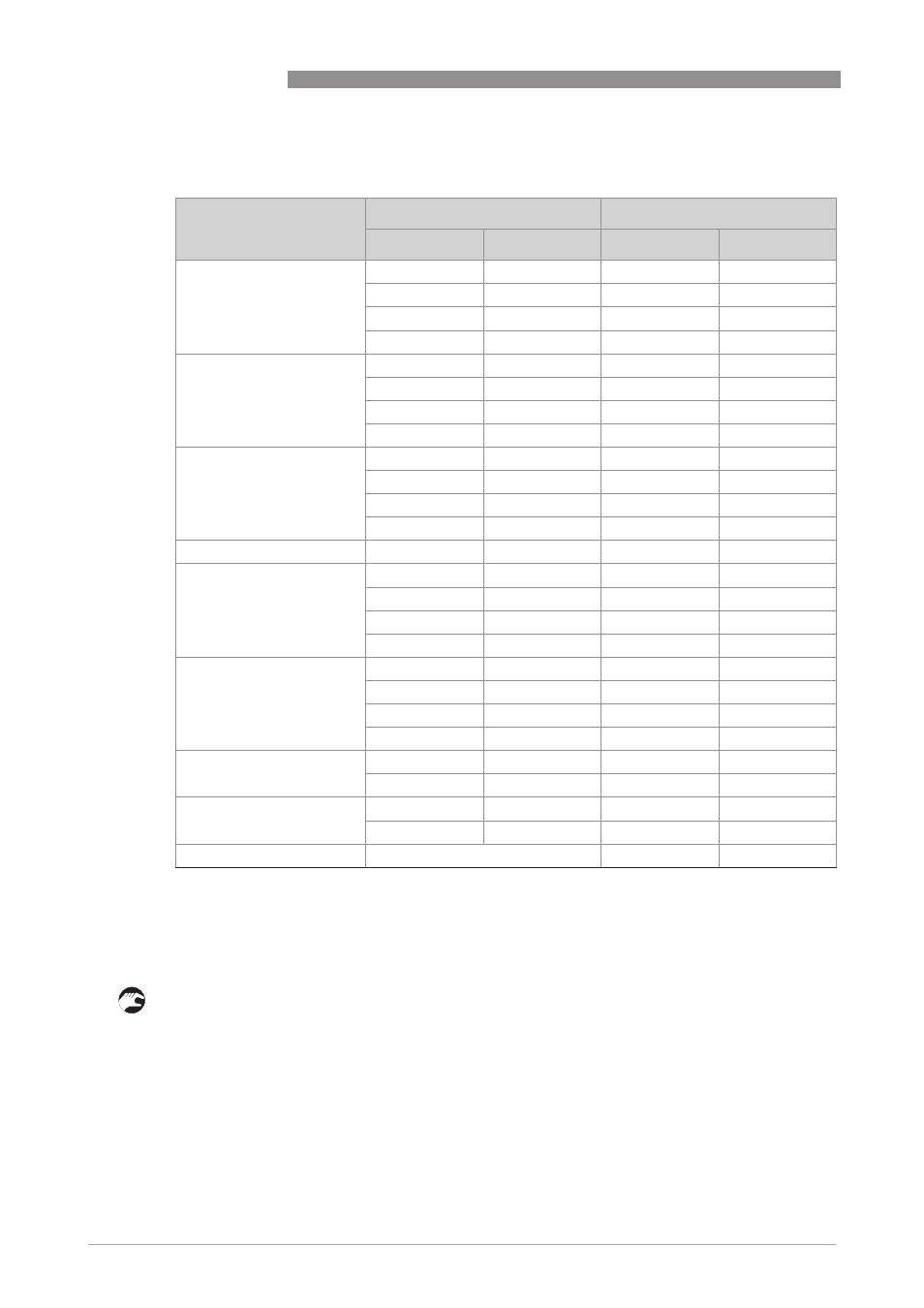

2.9.2 Installation of weld-on versions

For mounting sensors with weld-on connections, please follow the procedure as follows:

• Mount the sensor completely in the pipeline and spot the weld-on connections to the pipe. This

is necessary to align the mounting bores of the flange.

• Remove the sensor body and the gaskets from the adapters by loosen the screws.

• Weld the adapters completely to the pipe.

• When the pipe is cold again, reinstall the gasket and mount the sensor.

Type of connection

Size of connection

Max. operating pressure

mm

inch

bar

psig

Aseptic weld on for pipes to

DIN 11850

DN10...40

-

40

580

DN50...80

-

25

360

DN100

-

16

230

DN125...150

-

10

145

Aseptic weld on for pipes to

ISO 2037

12...38

-

40

580

51...76.1

-

25

360

101.6

-

16

230

114.3...139.7

-

10

145

Dairy screw to DIN 11851

1

DN10...40

-

40

580

DN50...80

-

25

360

DN100

-

16

230

DN125...150

-

10

145

Screwed to SMS 1145

1

25...100

-

6

90

Flanges to DIN 11864-2A

DN25...40

-

40

580

DN50...80

-

25

360

DN100

-

16

230

DN125...150

-

10

145

Clamp joint to ISO 2852

12…51

-

16

230

63.5...76.1

-

10

145

100

-

8

115

114.3...139.7

-

5

72

Clamp joint to DIN 32676

DN25...50

-

16

230

DN65...100

-

10

145

Clamp joint to Tri Clamp

-

1/2...3

20.5

295

-

4

13.8

200

Vacuum load

all versions and sizes

0 mbar abs.

0 psia

1 Without 3A mark