Flow fault circuit, Flow fault contacts, 2 start up – Detcon 972-041170-00L User Manual

Page 4

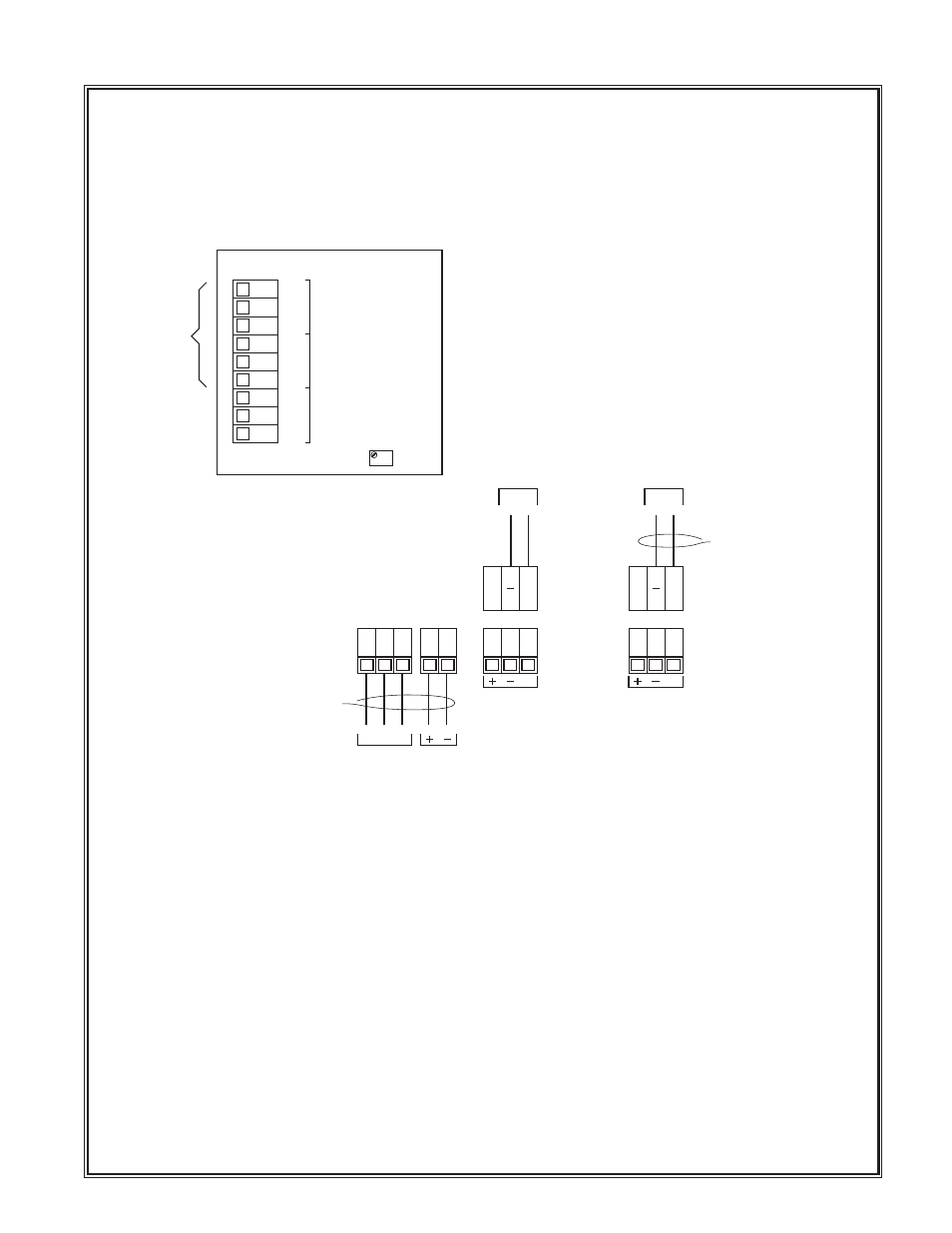

Caution: Observe correct polarity when terminating all input/output wiring. Failure to do so may result in

circuit damage on power up. Seethe field wiring diagram below for terminal locations.

4. Connect 117VAC to the connector labeled “117VAC IN”.

5. If applicable, connect 24 VDC battery backup to the connector labeled “24 VDC IN”.

6. If applicable, connect a remote recording device or computer to the 4-20 mA signal output connectors.

The terminals are labeled SENSOR “–” and “mA”.

8. If applicable, connect flow fault alarm wiring. Two sets of form C contacts (common, normally open and

normally closed) are provided. Relay contacts are rated 1 amp at 30VDC/.24 amp at 125VDC.

1.2 START UP

Upon completion of all tubing connections and field wiring turn on the power switch located on the enclo-

sure door. Note that the power lamp illuminates. If applicable, note that the sensor LCD indicators activate.

Varying readings may occur during sensor warm-up. Allow approximately 1 hour to stabilize (24 hours is best).

Also note air flow through the flow meter. Adjust the flow meter as necessary so that it falls between 500

and 1000 ml/m (milli liters per minute).

Detcon Model 972-041170-00L Gas Detection System PG.4

P7

P6

P5

L1

L2 GND

mA

117 VAC

IN

24 VDC

IN

Battery

Backup

SENSOR #1

Flow

Fault

Circuit

COM

NO

NC

1

COM

NO

NC

2

COM

NO

NC

3

PT1

mA

4-20mA

Wire 117 VAC & optional 24 VDC

backup to the lugless connectors.

Two discreet form C dry contacts are provided (2 & 3) by the

flow fault circuit for alarm devices. The first set of contacts

(1) are prewired to interrupt the 4-20mA signal output in the

event of a flow fault. This will allow for flow fault monitoring

at any controller/computer that the signal is wired in to.

P10

mA

SENSOR #2

mA

4-20mA

Wire th 4-20mA output signal to

the plug-type connnector

FLOW

FAULT

CONTACTS