Figure #1, Figure #2 – Detcon TP-524C User Manual

Page 8

3.5.2 Sensor Location

Selection of sensor location is critical to the overall safe performance of the product. Five factors play an important

role in selection of sensor locations:

(1) Density of the gas to be detected

(2) Most probable leak sources within the industrial process

(3) Ventilation or prevailing wind conditions

(4) Personnel exposure

(5) Maintenance access

Density - Placement of sensors relative to the density of the target gas is such that sensors for the detection of

heavier than air gases should be located within 4 feet of grade as these heavy gases will tend to settle in low lying

areas. For gases lighter than air, sensor placement should be 4-8 feet above grade in open areas or in pitched areas

of enclosed spaces.

Leak Sources - Most probable leak sources within an industrial process include f langes, valves, and tubing connec-

tions of the sealed type where seals may either fail or wear. Other leak sources are best determined by facility engi-

neers with experience in similar processes.

Ventilation - Normal ventilation or prevailing wind conditions can dictate efficient location of gas sensors in a

manner where the migration of gas clouds is quickly detected.

Personnel Exposure - The undetected migration of gas clouds should not be allowed to approach concentrated per-

sonnel areas such as control rooms, maintenance or warehouse buildings. A more general and applicable thought

toward selecting sensor location is combining leak source and perimeter protection in the best possible configuration.

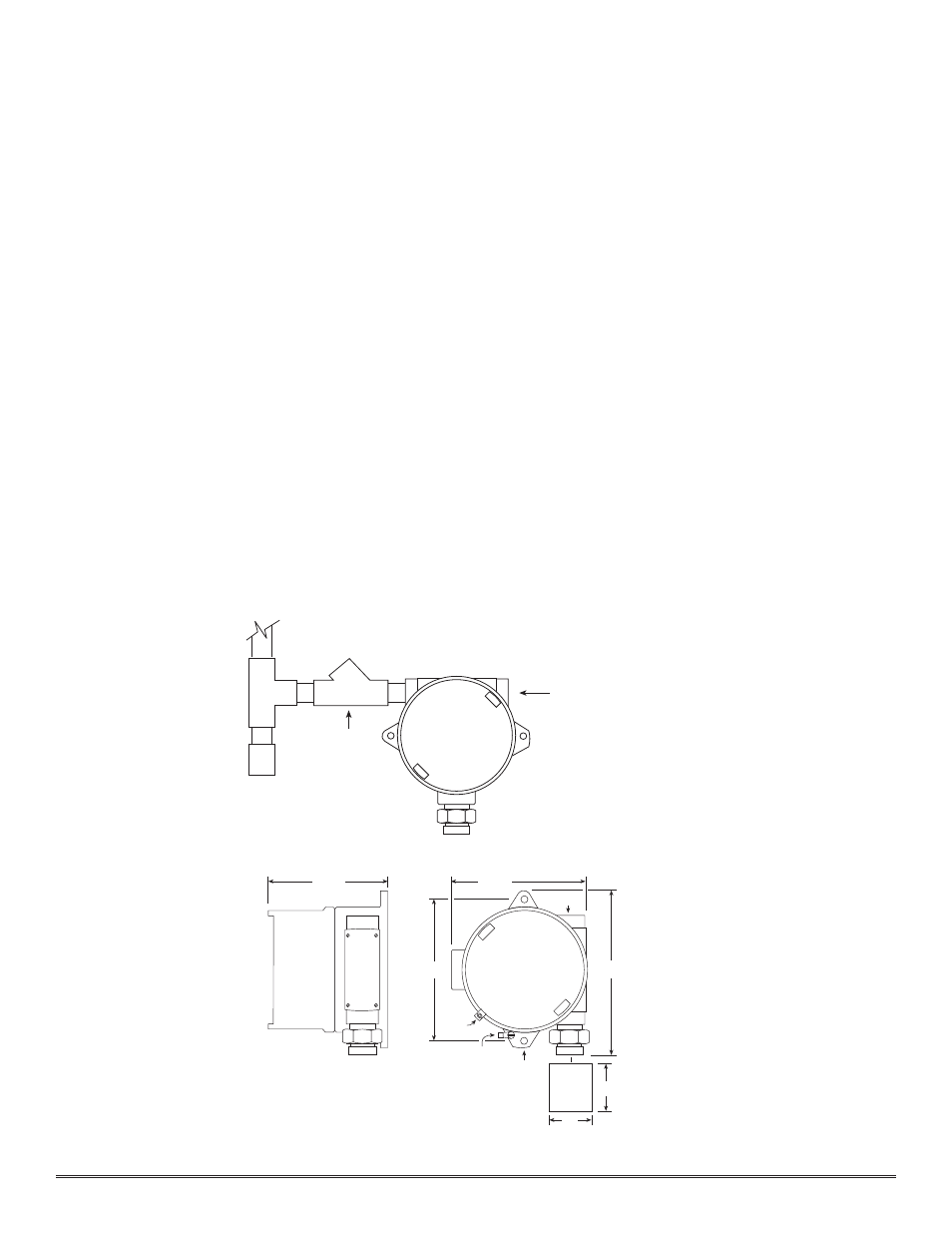

Detcon Model TP-524C Hydrogen Sulfide Sensor

PG.8

EYS

Seal

Fitting

Drain

“T”

Plug any unused ports.

Figure #1

4 3/4"

5 1/4"

3/4" NPT

Rain

Shield

2"

2 1/8"

1/4" Dia.

Mounting Holes

Grounding Lug

Cover

Set

Screw

5 1/2"

7"

Figure #2