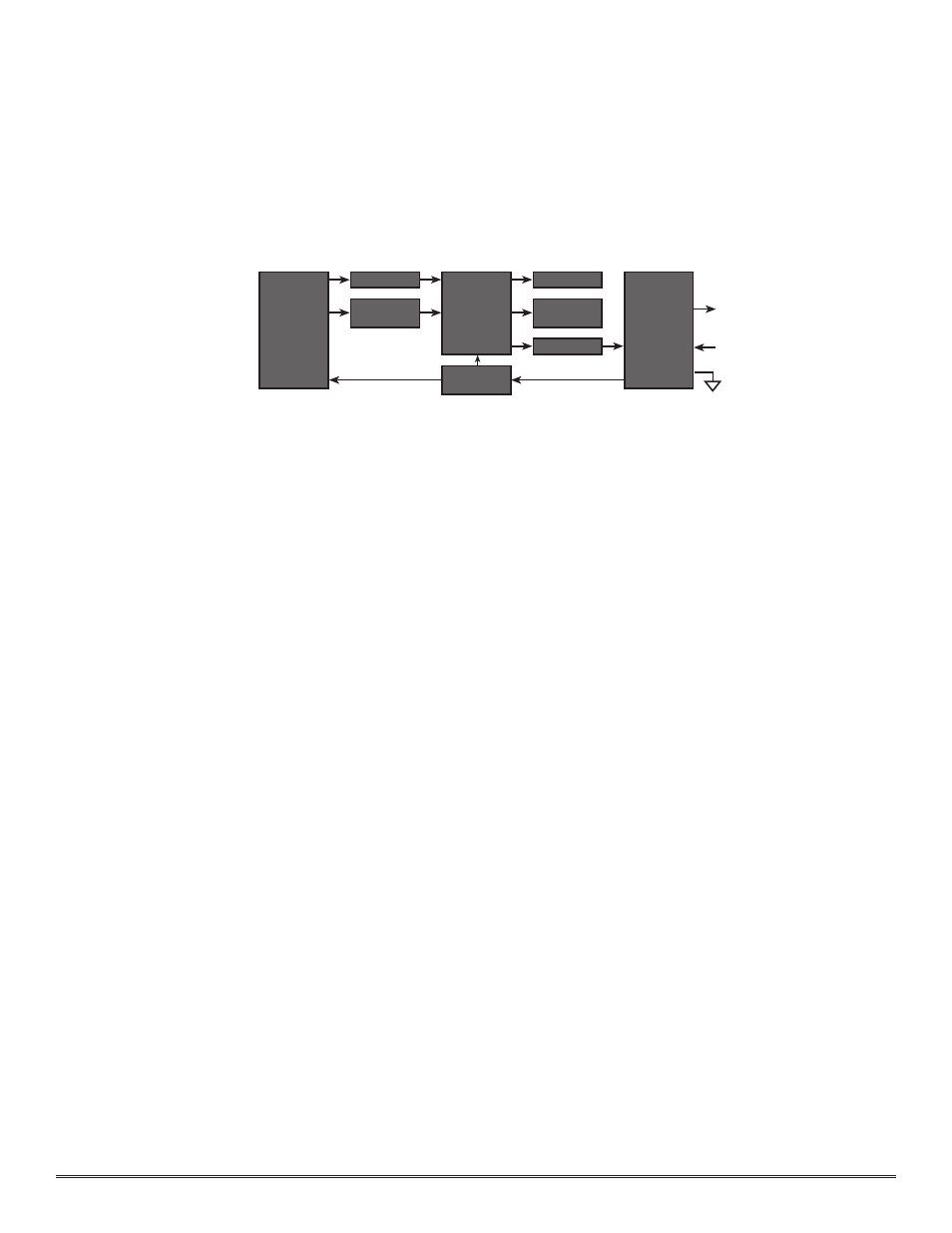

Functional block diagram – Detcon TP-524C User Manual

Page 5

The sensors are packaged in a cast metal explosion proof enclosure. The enclosure is f itted with a threaded cover

that has a glass lens window. Magnetic program switches located behind the transmitter module face plate are acti-

vated through the lens window via a hand-held magnetic programming tool allowing non-intrusive operator inter-

face with the sensor. Calibration can be accomplished without removing the cover or declassifying the area.

Electrical classif ication is Class I; Groups B, C, D; Division 1 (explosion proof).

3.1 P

RINCIPLE OF

O

PERATION

Method of detection is by diffusion/adsorption. Air and gas diffuse through a sintered stainless steel filter and contact

the heated surface of the metal oxide sensor film. As hydrogen sulfide gas molecules react with oxygen ions on the

film, there is a decrease in electrical resistance proportional to the gas concentration. The heater film elevates the tem-

perature of the sensor film creating convection and promoting a quick response to changing gas concentrations.

Electronically, the heater film is used to maintain a constant temperature of the sensor film enhancing stability and

repeatability. The sensor response is reversible and results in continuous monitoring of ambient air conditions.

3.2 A

PPLICATION

Model TP-524C MicroSafe™ sensors are designed to detect and monitor hydrogen sulfide gas in ambient air in the

range of 0-100 parts per million. The sensor can also be programmed to operate in the range 0-20 ppm or 0-50 ppm.

Minimum sensitivity and scale resolution is 1 ppm. Operating temperature range is --40° F. to +175° F. While the sen-

sor is capable of operating outside these temperatures, performance specifications are verified within the limit.

3.2.1 Sensor Placement/Mounting

Sensor location should be reviewed by facility engineering and safety personnel. Area leak sources and perimeter

mounting are typically used to determine number and location of sensors. Hydrogen sulf ide gas is slightly heavier

than air (approximately 1.18); therefore, the sensors are generally located 2 - 4 feet above grade.

3.2.2 Interference Data

Gas

PPM

Methane

25,000 = 0

Ethane

5,000 = 0

Hexane

5,000 = 0

Propane

5,000 = 0

Butane

5,000 = 0

Carbon Monoxide

800 = 0

Carbon Dioxide

5,000 = 0

Carbon Disulf ide

14 = 0

Methanol

200 = 0

Isopropanol

200 = 0

Ammonia

500 = 0

Diesel Fuel

1000 = 0

Dimethyl Sulf ide

4.4 = 0

Ethylene

200 = 0

Freon 12

1000 = 0

Hydrogen

5% = 0

Methyl Mercaptan

16 = 6

Sulfur Dioxide

300 = 0

Toluene

32 = 0

Ethanol

200 = 0

Detcon Model TP-524C Hydrogen Sulfide Sensor

PG.5

Analog 4-20 mA Out

Functional

Block

Diagram

Power In

Pre-Amp

Display

Temperature

Compensation

Cal & Fault

LEDs

4-20mA

Micro-

processor

Transmitter

Power Supply

Sensor

Element

I/O Circuit

Protection