8 initial start up – Detcon FP-624D-HT User Manual

Page 16

Model FP-624D-HT

FP-624D-HT Instruction Manual

Rev. 1.1

Page 12 of 44

AWG

Maximum Separation (feet)

20

50

18

75

16

125

14

175

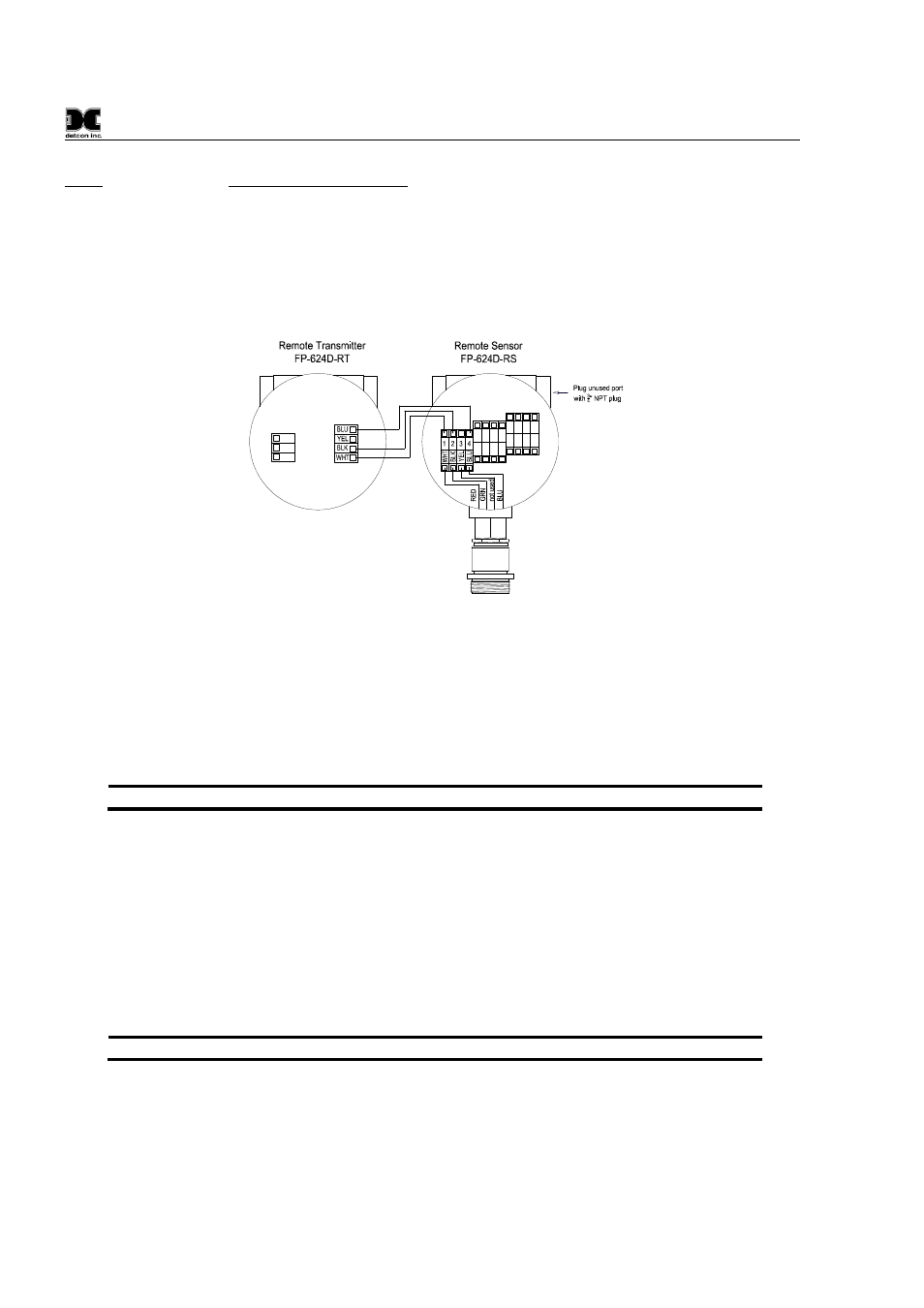

Reference Figure 11 for wiring diagram. Also note the jumper that is required on the remote sensor connector

board. Failure to install this jumper will cause a sensor fault condition.

Figure 11 Remote Sensor Wiring Diagram

2.7.1

Bridge Voltage Adjustment

When a sensor is remote mounted, consideration must be given to the lengths of cable used and how it affects

the sensor bridge voltage. Differing lengths of cables will have varying amounts of resistance which will shift

the sensor bridge voltage. Because of this, the bridge voltage will need to be adjusted after initial power up.

This adjustment is only required after initial installation and will not be necessary thereafter, except in the

event of replacement of the plug-in sensor. Refer to section 3.5.5 to perform this adjustment.

NOTE: Refer to section 3.5.5 to set the sensor bridge voltage.

2.8 Initial Start Up

Upon completion of all mechanical mounting and termination of all field wiring, apply system power in the

range of 12-28VDC (24VDC typical) and observe the following normal conditions:

a) FP-624D-HT display reads “0”, and no fault messages are flashing.

b) A temporary upscale reading may occur as the sensor heats up. This upscale reading will decrease to “0”

% within 1-2 minutes of power-up, assuming there is no gas in the area of the sensor.

NOTE: The 4-20mA signal is held constant at 4mA for the first two minutes after power up.

Initial Operational Tests

After a warm up period of 1 hour, the sensor should be checked to verify sensitivity to combustible gas.

Material Requirements