Important installation information, Suggested installation guide, Warning – SANDPIPER RHDF2 Hazardous Duty User Manual

Page 7

rhdf2dl1sm_haz duty-rev0614

Model RHDF2 Hazardous Duty Page 5

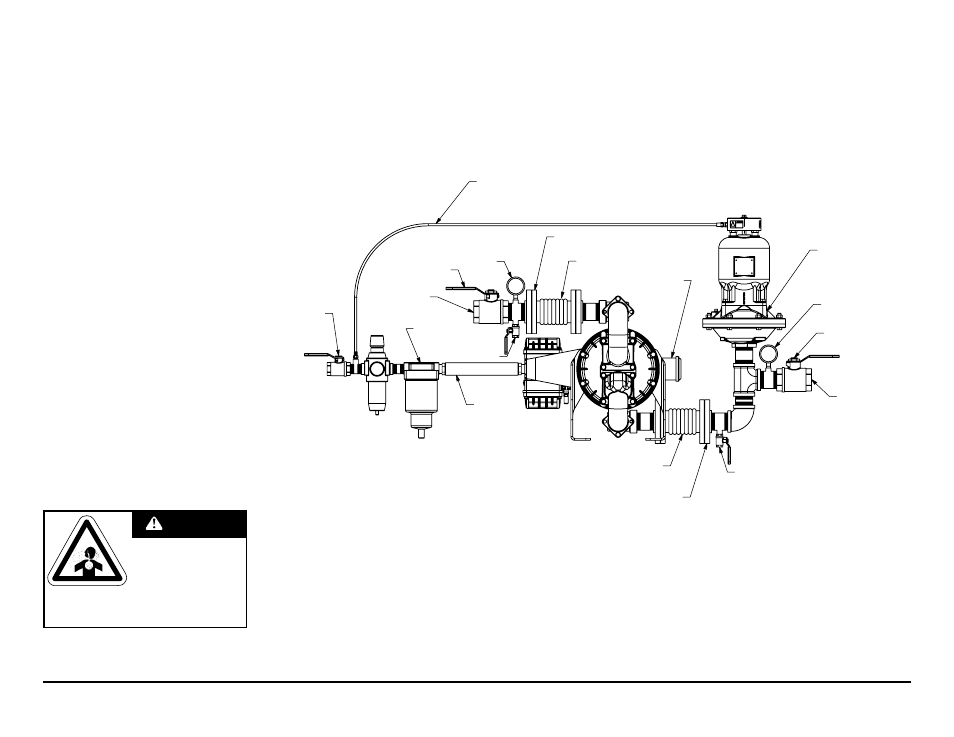

Warren Rupp Tranquilizer

Limited to 125 psi

(Optional)

Flexible Connector

Pipe Connection

(Style Optional)

Shut-Off Valve

Pressure Gauge

Drain Port

Muffler

(Optional Piped Exhaust)

Flexible

Connection

Dessicant Dryer

(Optional)

Unregulated Air

Supply to Tranquilizer

Filter Regulator

PN: 020.107.000

Shut Off

Valve

Flexible Connector

Pipe Connection

(Style Optional

Drain Port

Shut-Off Valve

Vacuum

Gauge

Note: Pipe weight should not be supported

by pump connections.

Suction Port

Discharge Port

Suggested Installation Guide

Important Installation Information

Use of the standard AODD Installation Guide is recommended for pumps

fitted with AirVantage technology. Install shut-off valves on both the suction and

discharge of the pump. (This will help limit the amount of product that enters the center section

of the pump in the event of a diaphragm failure.) Using shut-off valves in conjunction with a drain

port also provides a means of allowing the lines to be drained when maintenance needs to

be conducted.

WARNING

In the event of diaphragm

rupture, pumped material

may enter the air end of the

pump, and be discharged

into the atmosphere. If

pumping a product which is hazardous or toxic,

the air exhaust must be piped to an appropriate

area for safe disposition.

When the supply liquid level is above the air inlet of the pump, and a

diaphragm fails, the pumped liquid or fumes can enter the air end through

the point of failure. When a diaphragm failure is detected, it is best to close

the shut-off valves and bleed the lines of product. This will limit the ability

of the material being pumped to enter the AirVantage. Failure to do so may

result in damage to the AirVantage and air distribution components.

If a diaphragm failure has been detected in pumps

fitted with AirVantage, the following procedure for

shut-down must be used:

1. Close the suction shut-off valve

(this will limit any new product from

entering the pump)

2. Close the discharge shut-off valve

(this will stop any product from

reentering the pump)

3. Close the air supply shut-off valve

4. Drain the discharge line

5. Drain the suction line

6. Perform maintenance

Caution: When performing a direct spray washdown, a

plug must be installed in place of the AirVantage muffler.

Failure to do so may damage internal components. (See

page 23)