Airvantage servicing - sensor assembly – SANDPIPER RHDF2 Hazardous Duty User Manual

Page 29

rhdf2dl1sm_haz duty-rev0614

Model RHDF2 Hazardous Duty Page 27

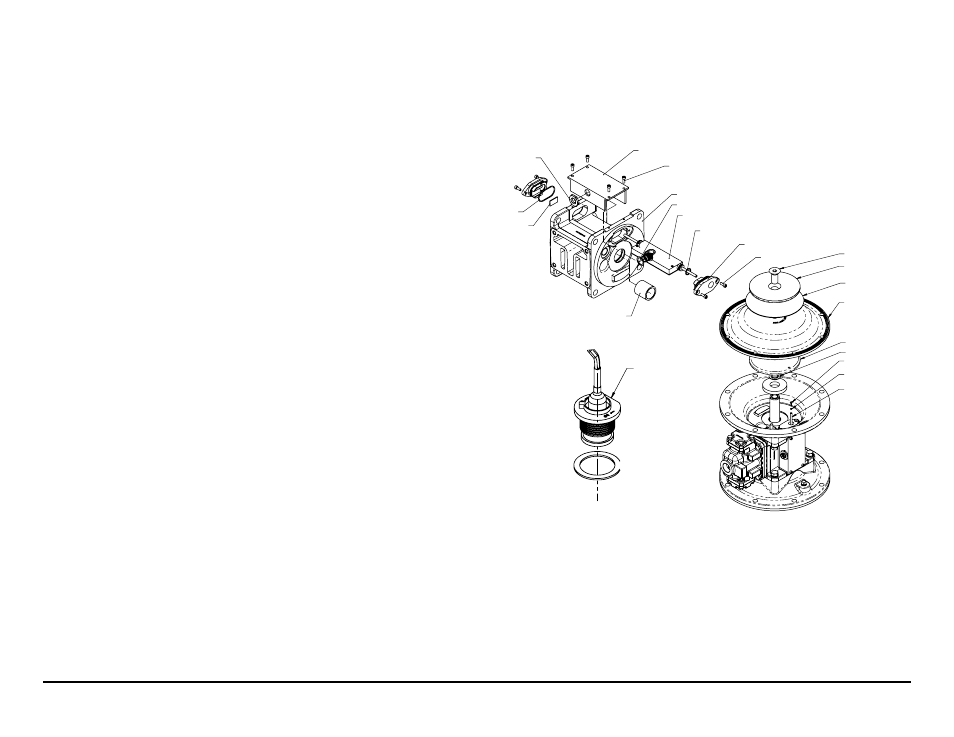

AirVantage Servicing - Sensor Assembly

To service the control module, first shut off and bleed the air being supplied to the pump. For safety

purposes the air supply line should be disconnected from the pump. Then shut off the suction and discharge

lines to the pump. Bleed the pressure from the pump suction and discharge lines and remove the lines from

the pump. During the servicing of the AirVantage, consult the “AirVantage Composite Repair Parts Drawing”.

Step #1: Remove the Patch Cable

• Twist the ribbed portion of the patch cable connector in a counterclockwise direction, until it unthreads

from the connector. The cable can either be removed from the intermediate or from the control module.

Step #2: Remove the AirVantage from the Pump

• Use a ½” socket and remove the four 5/16-18 x 5 ½ cap screws that hold the AirVantage to the pump.

Be sure to support the weight of the AirVantage while removing the last cap screw. After the AirVantage

is removed from the pump, set the unit down on the plastic cover located on the bottom. Inspect the

o-ring between the poppet valve and the adapter plate for damage.

Step #3: Diaphragm Disassembly

• Refer to the “Diaphragm Servicing” section (p.15) of the manual to remove diaphragm assembly from

the pump.

• “AirVantage CAUTION” – When the diaphragm assembly is removed, watch for the brass probe

tips located on the end of the sensor rod. There is one brass probe tip and one o-ring per side.

Inspect the probe tips and o-rings for wear. For every diaphragm service, these parts should be

replaced and are available in kit form. Consult the “Composite Repair Parts Drawing” for part

numbers and quantities.

Step #4: Accessing the Sensor Assembly

• Use a ¼” hex key wrench and remove the four, flat head socket cap screws on each inner chamber.

These bolts have been assembled using blue thread locker, so they may be difficult to remove. The

inner chambers and gaskets can now be removed.

• “AirVantage CAUTION” – Remove the inner chamber from the intermediate with caution, taking

care not to damage the sensor.

• If the sensor needs to be replaced, use a 13/16” socket and remove the plastic nut holding the

connector to the intermediate. Slide the connector out of the hole.

• The sensor can now be removed from the intermediate assembly.

Step #5: Reinstallation

• Slide the new sensor assembly in the intermediate.

• “AirVantage CAUTION” – Make sure the cable assembly fits into the groove machined in the

intermediate. Failure to do so may damage the cable during assembly.

• Feed the connector through the hole in the intermediate and install the plastic nut. Hand tighten the nut

using a 13/16" socket. Make sure the gasket is to the inside of the intermediate.

• The inner chambers and gaskets can now be reinstalled. Use blue thread locker on the inner chamber

bolts and torque them to 300 in-lbs.

• Refer to the “Diaphragm Servicing” section of the manual to finish the diaphragm installation procedure.

Note: Refer to Composite Repair Parts List on

page 12 for part numbers

Page 17

PROBE TIP

O-RING

SENSOR, FEED BACK

WASHER, SEALING

PLATE, DIAPHRAGM

DIAPHRAGM

PAD, WEAR

PLATE,

OUTER DIAPHRAGM

CAPSCREW

SENSOR COVER

CAPSCREW

END CAP

FEED BACK SENSOR

O-RING

CAPSCREW

INTERMEDIATE

JAM NUT

O-RING

FOAM BUMPER

BEARING

SEAL

A

BRACKET, INTERMEDIATE, ASSEMBLY

SENSOR, FEEDBACK

NUT

SEAL

DIAPHRAGM

PLATE,

OUTER DIAPHRAGM

PLATE,

INNER DIAPHRAGM

PROBE TIP

O-RING

SENSOR, FEEDBACK

BUMPER

DETAIL A

FLAT EDGE