Check valve drawing – SANDPIPER M05 Metallic User Manual

Page 30

m05mdl1sm-rev0711

Model M05 Metallic Page 28

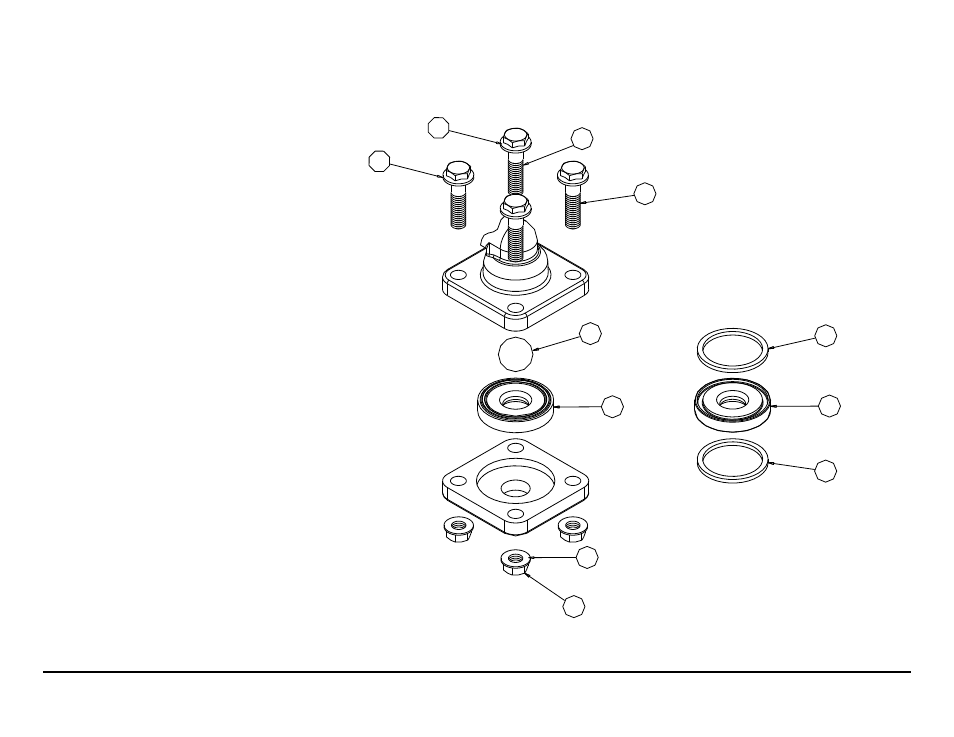

Check Valve Drawing

CHECK VAlVE SERVICING

Before servicing the check valve

components, first shut off the suction

line and then the discharge line to the

pump. Next, shut off the compressed

air supply, bleed air pressure from the

pump, and disconnect the air supply

line from the pump. Drain any remaining

fluid from the pump. The pump can now

be removed for service.

To access the check valve

components, remove the manifold/

manifold assembly. Use a 1/2" wrench

or socket to remove the fasteners. Once

the manifold is removed, the check

valve components can be seen.

Inspect the check balls (items 2) for

wear, abrasion, or cuts on the spherical

surface. The check valve seats (item

36) should be inspected for cuts,

abrasive wear, or embedded material

on the surfaces of both the external

and internal chambers. The spherical

surface of the check balls must seat

flush to the surface of the check valve

seats for the pump to operate to

peak efficiency. Replace any worn or

damaged parts as necessary.

Re-assemble the check valve

components. The seat should fit into

the counter bore of the outer chamber.

The pump can now be reassembled,

reconnected and returned to operation.

METAllIC SEATS

Two o-rings (or conductive PTFE

seals) (item 29) are required for metallic

seats.

37

37

9

10

2

36

27

37

29

36

29