Installation, operation & maintenance – SANDPIPER WR10 3/8 User Manual

Page 6

Page 3 Rev 0614

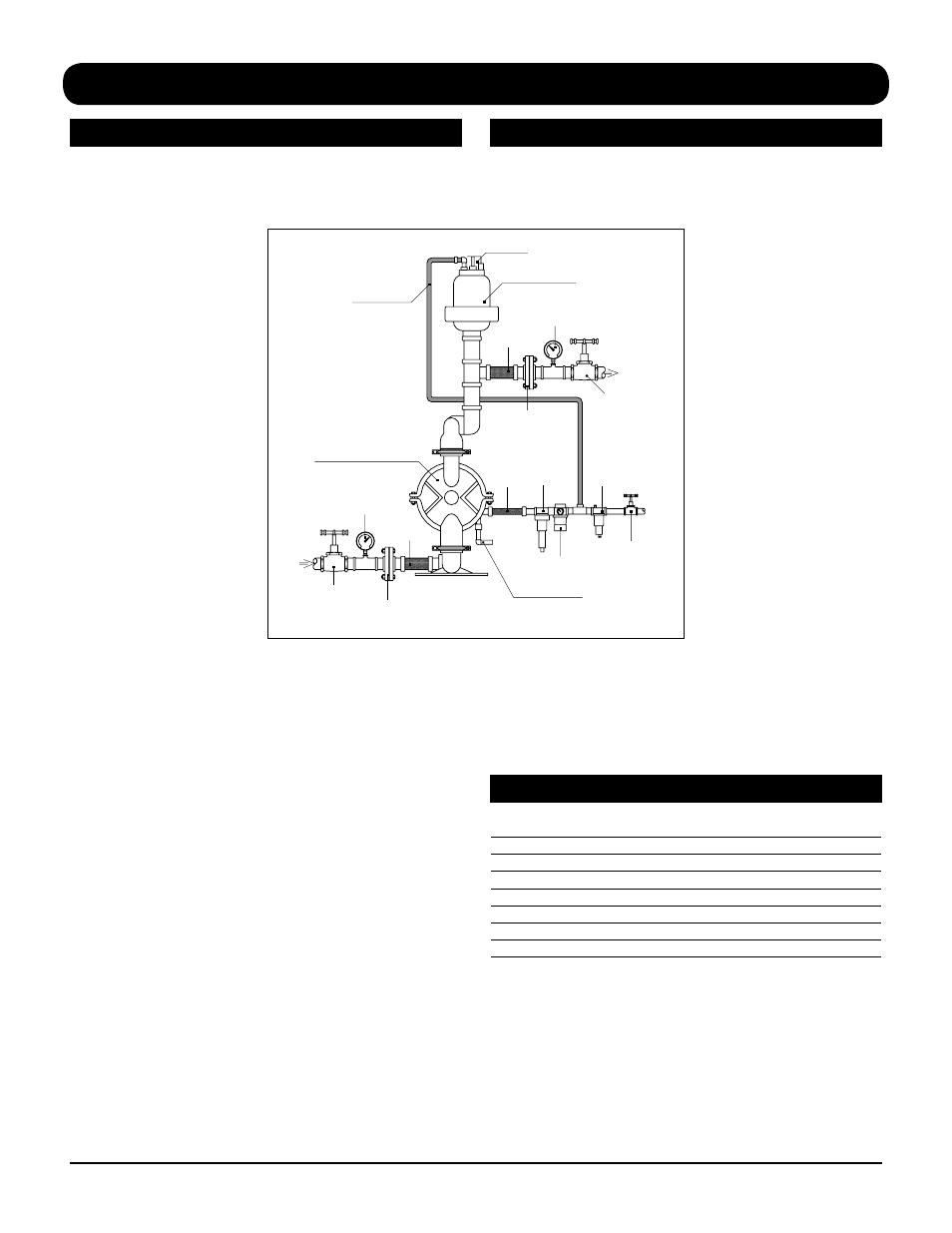

The pump should be mounted in a vertical

position. In permanent installations, the pump should be

attached to plant piping using a flexible coupling on both the

intake and discharge con-

nections to reduce vibration

to the pump and piping. To

further reduce vibration, a

surge suppressor next to the

pump may

be used.

Suction pipe size should be

at least the same diameter

as the inlet connection size,

even larger if highly viscous

fluid is to be pumped. If suc-

tion hose is used, it must be

of a non-collapsible

reinforced type.

Discharge piping should be

of at least the same diameter

as the discharge connection.

It is critical, especially on the

suction side of the pump, that

all fittings and connections are air tight or pumping efficiency

will be reduced and priming will be difficult.

Make certain the air supply line and connections

and compressor are capable of supplying the

required pressure and volume of air to operate

the pump at the desired flow rate. The quality of

the compressed air source should be considered.

Air that is contaminated with moisture and dirt

may result in erratic pump performance and

increased maintenance cost as well as frequent

process “down time” when the pump fails to

operate properly.

The pump is powered by compressed air.

Compressed air is directed to the pump air

chamber by the main air valve. The compressed air is sepa-

rated from the

fluid by a membrane called a diaphragm.

The diaphragm in turn applies pressure on

the fluid and forces it

out of the pump

discharge. While this is

occurring, the opposite air

chamber is

depressurized and

exhausted to

atmosphere and fluid is

drawn into the pump suction.

The cycle again repeats, thus

creating a constant recipro-

cating action which maintains

flow through the pump.

The flow is always in through

the bottom

suction connection and out

through the top

discharge connection. Since

the air pressure acts directly

on the diaphragms, the pres-

sure applied to the fluid

roughly approximates the air supply

pressure supplied to the main air valve.

INSTALLATION, OPERATION & MAINTENANCE

Installation

Pump Operation

Shut Off Valve

Air Stop Valve/

Needle Valve

Filter

Separator

Pressure-reducing

Valve

Fluid

Inlet

Discharge Pressure

Gauge

Manometer

Shut Off Valve

Air Connection

Fluid

Discharge

AODD PUMP

Air Exhaust

Air Exhaust Muffler

Pulsation Dampener

Union or Pipe Flange

Connection

Union or Pipe Flange

Connection

Flexible

Connection

Flexible

Connection

Flexible

Connection

Pump Size Minimum Air Line Size Minimum Suction Line

Size

1/4"

1/4"

1/4"

3/8"

1/4"

3/8"

1/2"

1/2"

1/2"

1"

1/2"

1"

1-1/2"

1/2"

1-1/2"

2"

1/2"

2"

3"

3/4"

3"

Recommended Piping Connections