RIKON Power Tools 70-300 User Manual

Page 9

9

AC Inverter does not require any programming. It is pre-programmed from the factory. The

buttons and knob on the face of inverter should not be changed. Use only controls on the

front of headstock. Refer to Inverter manual.

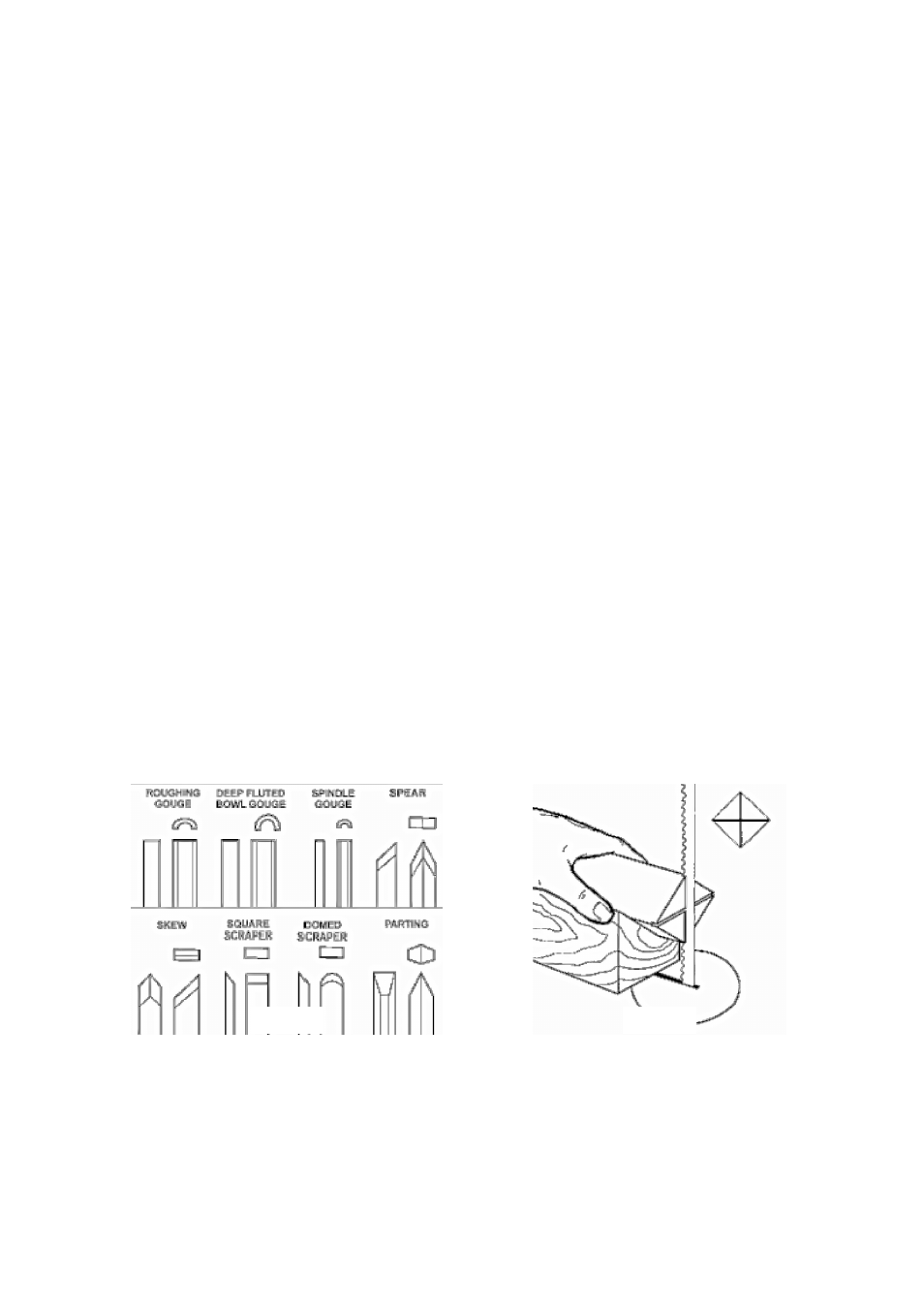

Lathe Tools

If possible, select only high quality, high speed steel turning tools with long handles. As one becomes

proficient in turning, a variety of specialty tools for specific applications can be acquired. The following

tools provide the basics for most woodturning projects.

Roughing Gouge - used for rapidly cut raw wood into round stock, see Figure 9.

Deep Fluted Bowl Gouge - used for turning bowls and plates, see Figure 9.

Spindle Gouge - used for turning beads, coves and other details, see Figure 9.

Spear - fine scraping and delicate operations, such as the forming of beads, parallel grooves and

shallow vees, etc, see Figure 9.

Skew - used to make vees, beads, etc., see Figure 9.

Square Scraper - used for diameter scraping and featureless scraping, etc, see Figure 9.

Large Domed Scraper - used to reduce ridges on the interior of bowls, round edges of bowls, etc,

see Figure 9.

Parting Tool - used to cut directly into the material, or to make a cut off. Also used for scraping and to

set diameters, see Figure 9.

For safety and best performance,

keep tools sharp. If a tool stops cutting, or requires excessive

pressure to make a cut, it needs to be sharpened. A number of brand name sharpening jigs and fix-

tures are available, however, a woodturner should learn to sharpen tools freehand.

Fig. 9

Fig. 10

Mounting Work piece Between Centers

Spindle turning takes place between the centers of the lathe. It requires a spur center in the head-

stock and a live center in the tailstock.