RIKON Power Tools 70-300 User Manual

Page 7

7

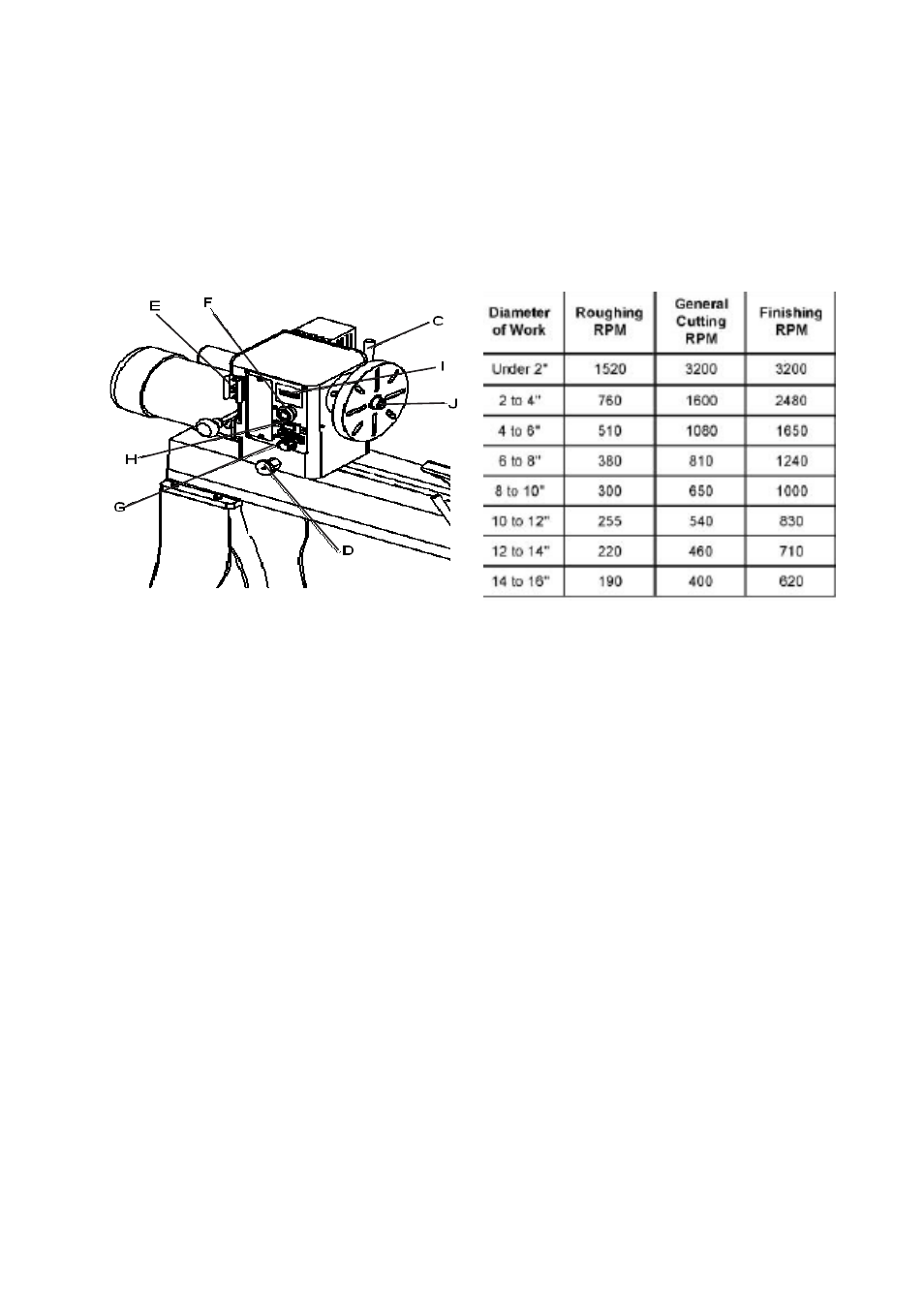

Fig. 3

Fig. 4

7.

Headstock RPM Readout: (I, Fig. 3) Displays the spindles RPM, see Figure 4.

8.

Headstock Spur Center: (J, Fig. 3) Used for turning between centers. Spindle taper is MT-2.

Remove spur center by inserting drift rod through the opposite end of the spindle and knocking spur

center out.

9.

Headstock Faceplate: (K, Fig. 3) Used for turning bowls and plates. There are a number of screw

holes for mounting the work piece. Thread the faceplate onto the spindle in a clockwise direction, and

tighten two set screws. Remove the faceplate by loosening two set screws. Push in headstock spindle

lock and use the provided rod in faceplate holes to unthread the faceplate.

10.

Headstock Indexing Hole: (L, Fig. 5) Thread indexing pin into the indexing hole making sure that

it locates in the spindle hole. There are 12 holes in the spindle 30° apart. There are three holes in the

headstock casting that accept the indexing pin. These holes are 20° apart. The combination of holes

will allow you to mark your workpiece for evenly spaced features. CAUTION! Never start the lathe

with the index pin engaged in the spindle!

11.

Tool Rest Body Lock Handle: (M, Fig. 6) Locks the tool rest body in position. Unlock handle to

position the tool rest in any location along lathe bed. Tighten handle when properly positioned.

12.

Tool Rest Lock Handle: (N, Fig. 6) Locks the tool rest in position. Unlock the handle to position

tool rest at a specific angle, or height. Tighten handle when properly positioned.

4. Headstock On/Off Button: (F, Fig.3) Pull the button out to turn “ON” the lathe. Push the button in to

turn the lathe “OFF”.

5. Headstock RPM Knob: (G, Fig. 3) Turn knob to desired RPM. There are two speed ranges offering

“speed” (0-3200) and “torque” (0-1200).

6. Headstock For/Rev Switch: (H, Fig. 3) Use the toggle switch to change the direction the spindle

turns. Only change direction when the spindle has stopped.