Operation – Lincoln Electric IM954 VANTAGE 500 DEUTZ User Manual

Page 24

B-7

OPERATION

B-7

The VANTAGE® 500 DEUTZ and any high frequency

generating equipment must be properly grounded.

See the K930-2 TIG Module operating manuals for

complete instructions on installation, operation, and

maintenance.

When using the TIG Module, the OUTPUT control on

the VANTAGE® 500 DEUTZ is used to set the maxi-

mum range of the CURRENT CONTROL on the TIG

Module or an Amptrol if connected to the TIG Module.

VANTAGE® 500 DEUTZ SETTINGS WHEN USING

THE K930-2 TIG MODULE

• Set the WELD MODE switch to the “Touch Start TIG

20-250 Setting”.

• Set the IDLER switch to the “AUTO” position.

• Set the WELDING TERMINALS switch to the

“Remotely Controlled” position. This will keep the

solid state contactor open and provide a “cold” elec-

trode until the triggering device (Amptrol or Arc Start

Switch) is pressed.

VANTAGE® 500 DEUTZ

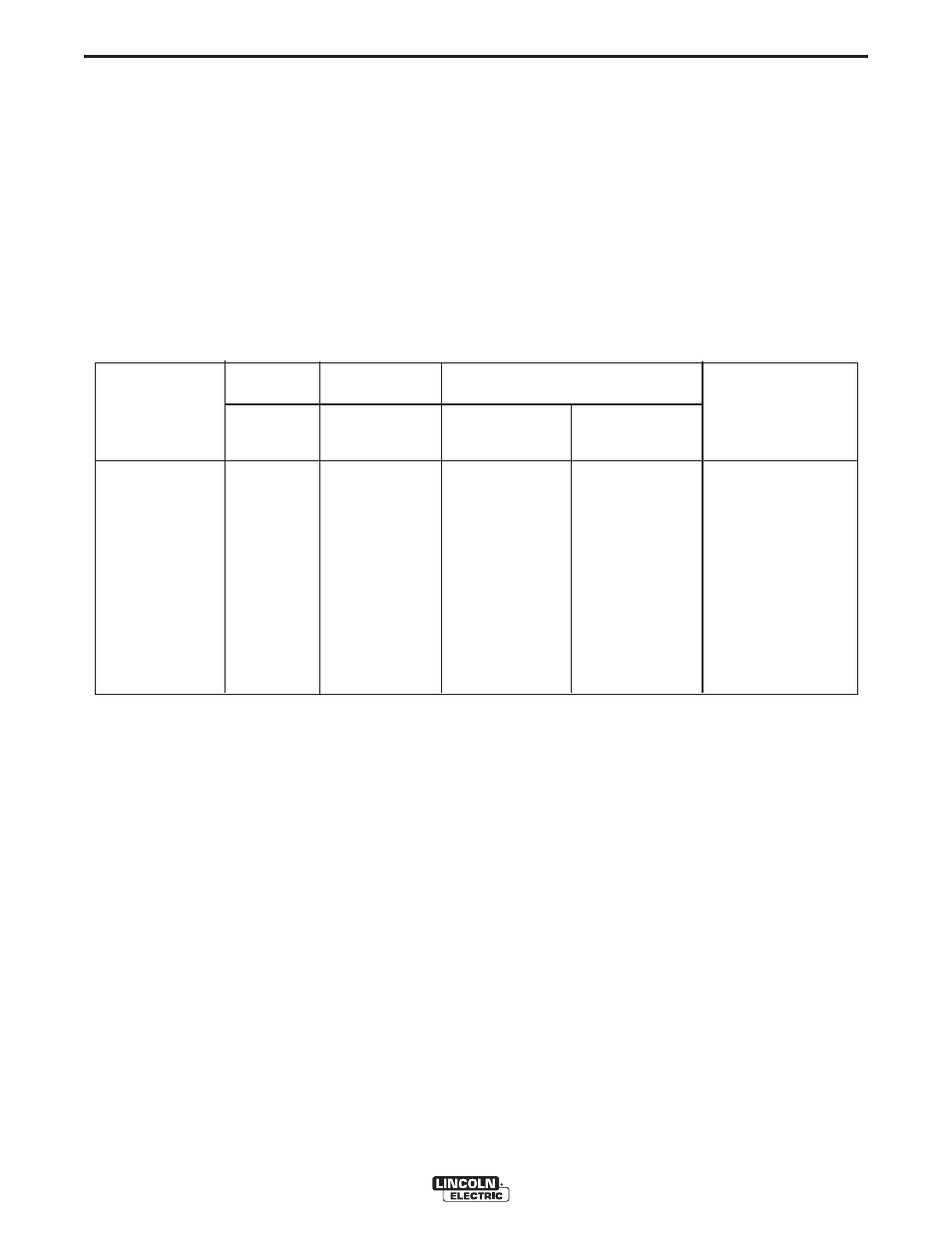

Table B.3 TYPICAL CURRENT RANGES

(1)

FOR TUNGSTEN ELECTRODES

(2)

DCEN (-)

DCEP (+)

Approximate Argon Gas Flow Rate

l/min (c.f.m.)

Tungsten

Electrode

1%, 2%

1%, 2%

TIG TORCH

Diameter

Thoriated

Thoriated

Aluminum

Stainless Steel

Nozzle

mm (in)

Tungsten

Tungsten

Size (4), (5)

.25 (0.010)

2-15

(3)

2-4 (3-8)

2-4 (3-8)

#4, #5, #6

.50 (0.020)

5-20

(3)

3-5 (5-10)

3-5 (5-10)

1.0 (0.040)

15-80

(3)

3-5 (5-10)

3-5 (5-10)

1.6 (1/16)

70-150

10-20

3-5 (5-10)

4-6 (9-13)

#5, #6

2.4 (3/32)

150-250

15-30

6-8 (13-17)

5-7 (11-15)

#6, #7, #8

3.2 (1/8)

250-400

25-40

7-11 (15-23)

5-7 (11-15)

4.0 (5/32)

400-500

40-55

10-12 (21-25)

6-8 (13-17)

#8, #10

4.8 (3/16)

500-750

55-80

11-13 (23-27)

8-10 (18-22)

6.4 (1/4)

750-1000

80-125

13-15 (28-32)

11-13 (23-27)

(1)

When used with argon gas. The current ranges shown must be reduced when using argon/helium or pure helium shielding gases.

(2)

Tungsten electrodes are classified as follows by the American Welding Society (AWS):

Pure EWP

1% Thoriated

EWTh-1

2% Thoriated

EWTh-2

Though not yet recognized by the AWS, Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated Tungsten in AC

and DC applications.

(3)

DCEP is not commonly used in these sizes.

(4)

TIG torch nozzle “sizes” are in multiples of 1/16ths of an inch:

# 4 =

1/4 in.

6 mm

# 5 =

5/16 in.

8 mm

# 6 =

3/8 in.

10 mm

# 7 =

7/16 in.

11 mm

# 8 =

1/2 in.

12.5 mm

#10 =

5/8 in.

16 mm

(5)

TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are less prone to

breakage, but cannot withstand high temperatures and high duty cycles.