Troubleshooting, Caution – Lincoln Electric IM611 TIG PULSER User Manual

Page 17

D-3

TROUBLESHOOTING

D-3

TIG PULSER

Observe all Safety Guidelines detailed througout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local

Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

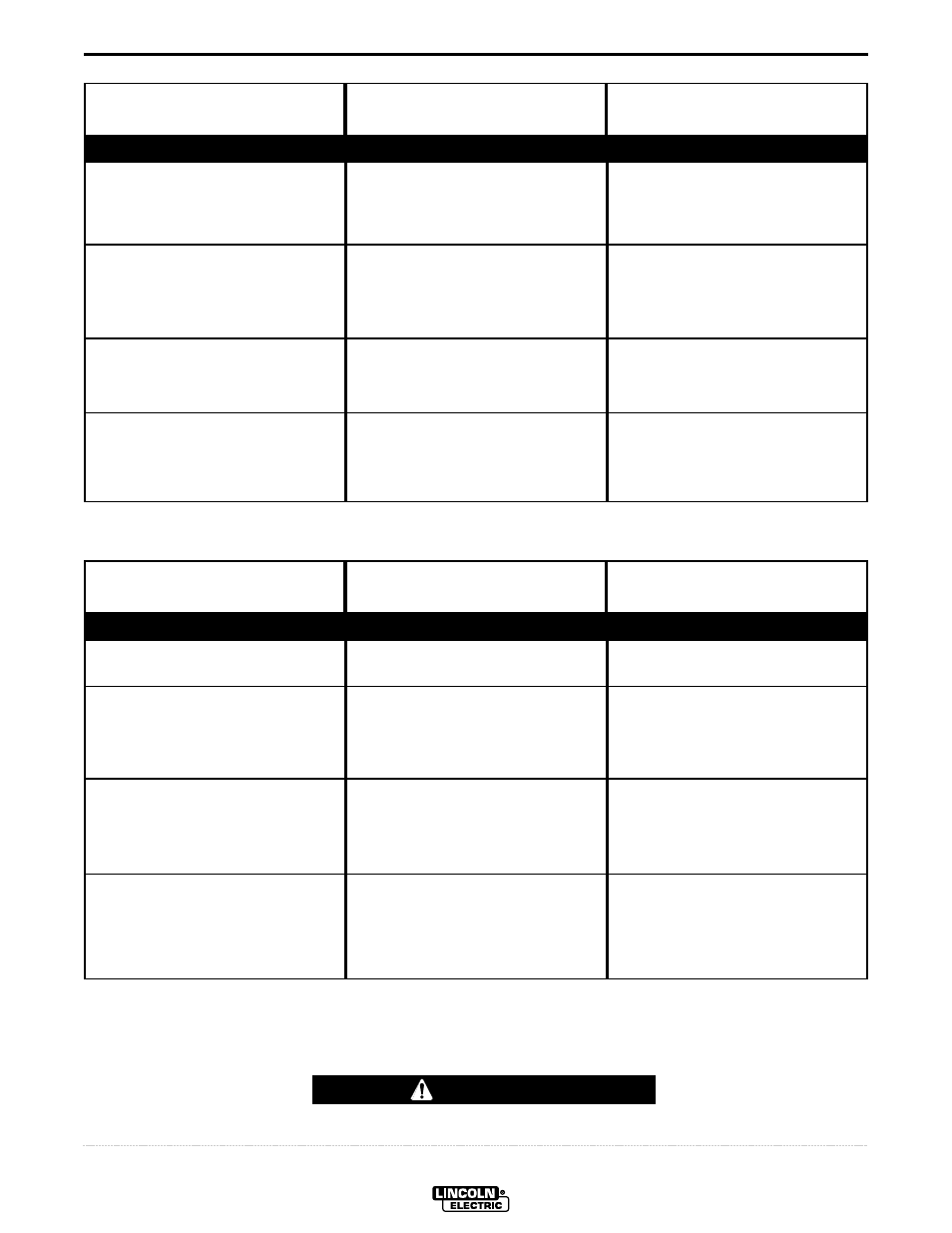

2-STEP TIG WELDING PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

Hi-Freq kicking in and out while weld-

ing in DC.

No Hi-Freq or no gas, can not start.

Low welding current.

Does not pulse.

1. Background Current is set too low.

2. Defective power source.

1. Power source & Tig Pulser con-

nection is wrong.

2. Defective power source.

1. Power source is set at 4-step Tig.

2. Defective Pulser PC board.

1. MODE switch on Tig Pulser is set

at 4-step.

2. Defective Pulser PC board.

1. Set Background Current to desired

position.

2. Check power source.

1. See Installation & Connection section

for proper connection.

2. Check power source.

1. Set power source to 2-step TIG.

2. Replace Pulser PC board.

1. Set MODE switch on Tig Pulser to 2-

step.

2. Replace Pulser PC board.

4-STEP TIG WELDING PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

Does not pulse when trigger closed.

Does not pulse when trigger open.

No output.

Welding current goes off after start-

ing.

Nothing is wrong, only pulse during

welding when trigger is open.

1. MODE switch on Tig Pulser is not

set at 4-step.

2. Defective Pulser PC board.

1. Mode switch on power source is

set at 2-step TIG.

2. Defective power source.

1. Background Current and/or Peak

Current set too low.

2. Defective power source.

1. Set MODE switch to 4-step.

2. Replace Pulser PC board.

1. Set MODE switch on power source to

4-step.

2. Check power source.

1. Set Background Current and Peak

Current to desired position.

2. Check power source.