Operation, Design features and advantages, Welding capability – Lincoln Electric IM611 TIG PULSER User Manual

Page 12: Limitations, Power source settings, Tig pulser controls and settings

B-2

OPERATION

B-2

DESIGN FEATURES AND ADVANTAGES

• Simple controls make this unit easy to set up and

adjust.

• Operating power provided through the remote control

cable receptacle eliminating the need for an indepen-

dent power supply.

• Accomodates Amptrol or Arc Start Switch in 2-step or

4-step trigger mode.

• Designed to the IEC-974-1 standard.

• Attractive, rugged case includes carrying handle and

rubber feet.

• Unit is supplied with one bracket for hanging on the

power source, and one “universal” bracket for mount-

ing to vertical or horizontal surfaces.

WELDING CAPABILITY

The TIG Pulser provides GTAW-P capability for the SW

TIG power source up to 90% of the maximum current

capacity of the machine.

LIMITATIONS

At the time of printing, the TIG Pulser is only recom-

mended for use with the SW TIG 175 and the SW TIG

275 power source for GTAW-P (pulse TIG) procedures

within the capacity of the TIG power source. Check

power source Operator’s Manual before using with the

TIG Pulser.

TIG PULSER

POWER SOURCE SETTINGS

The power source AMPERAGE control knob must be

set at MAX. and the mode switch must be set at 2-step

or 4-step TIG. The polarity switch and other control

knobs on the power source can be set at any desired

position and will have the same effect as being operat-

ed without the TIG Pulser.

TIG PULSER CONTROLS AND SETTINGS

Refer to Figure B.1.

MODE switch

Located on the top side of the TIG Pulser. Set this

switch to one of the following three postitions:

• Set to Amptrol 2-step if welding in 2-step and want to

remotely control the welding current with a hand

Amptrol or a foot Amptrol.

• Set to Arc Start Switch 2-step if welding in 2-step

with an Arc Start Switch. Welding may be performed

in this mode with a hand Amptrol or a foot Amptrol,

however the current will not be remotely controlled

but controlled by the setting on the pulser

• Set to 4-step if welding in 4-step and the power

source is set to 4-step. Either an Arc Start Switch or

an Amptrol can be used, however current can only

be controlled by the pulser setting. Refer to the

power source instruction manual for 4-step TIG oper-

ation.

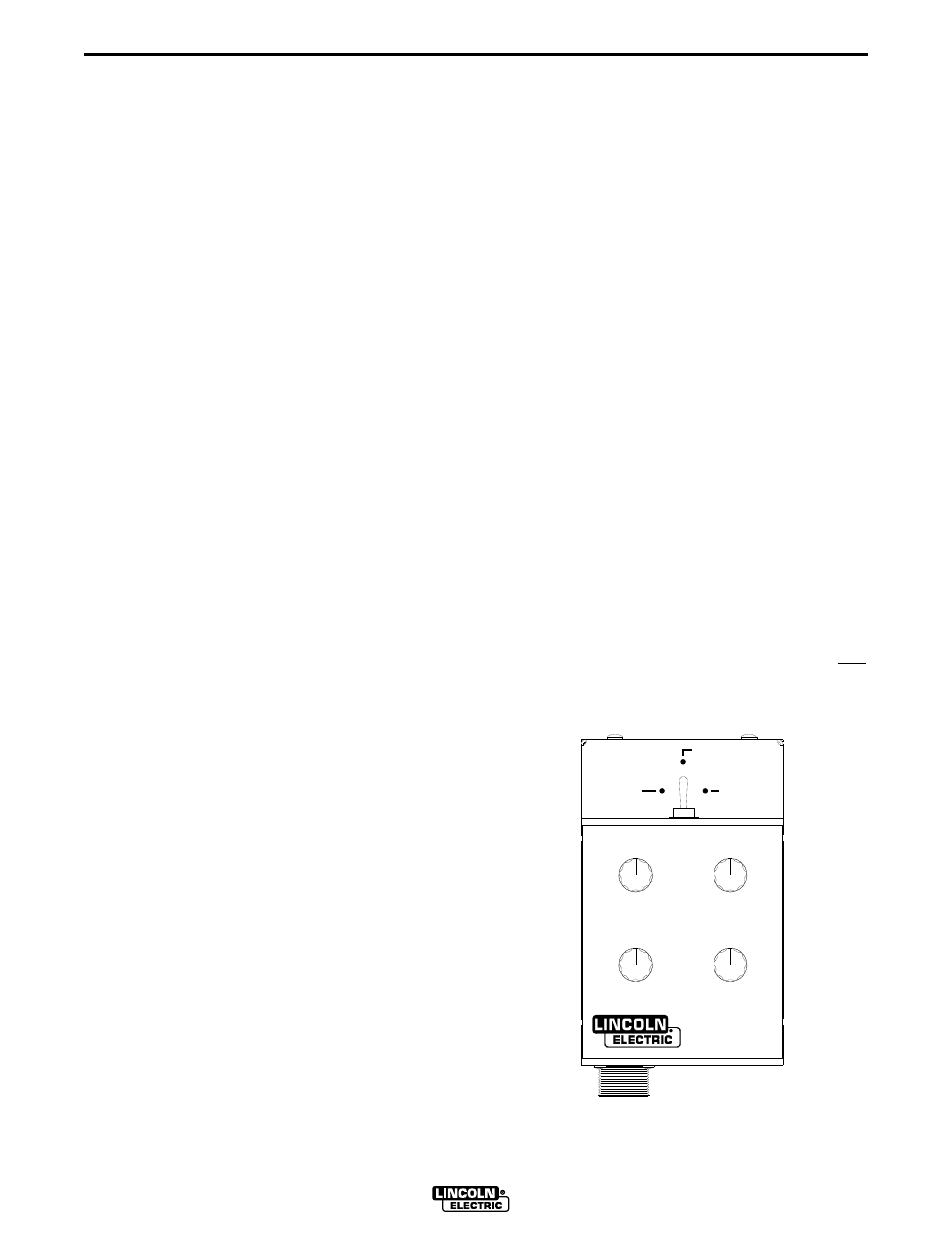

Figure B.1 TIG PULSER Controls

AMPTROL

2-STEP

PEAK

CURRENT

BACKGROUND

CURRENT

PULSES PER

SECOND

ARC START SWITCH

2-STEP

ARC START

SWITCH

OR AMPTROL

4-STEP

% ON TIME

TIG PULSER