Installation, General description, Standard features – Lincoln Electric IM559 Synergic 7F and 7FH User Manual

Page 9: Recommended processes and equipment

A-2

INSTALLATION

SYNERGIC 7F & FH

A-2

GENERAL DESCRIPTION

The Synergic 7F is a CSA / NRTL/C certified semiautomatic

constant speed wire feeder designed specifically for use

with the Invertec Power Wave type power sources. This

boom or fixture mounting wire feeder consists of a Synergic

7F Control Box and the choice of the standard Synergic 7F

or High Speed Synergic 7FH wire feed unit and connecting

cable assemblies. A serial communication link is supplied

through the input control cable of the Synergic 7F enabling

information to be shared between the power source and

wire feeder control. The 4-Roll Synergic 7F wire feed units

come factory equipped with gas solenoid valve with gas fit-

tings and standard Lincoln gun connector and connector for

an optional dual procedure gun switch. Control includes a

3-1/2 digit LED display with rotating knob encoder controls

for setting the wire feed speed and voltage. A tactile-feel

keypad provides selection of operating mode, function

selection, timer and crater fill selection and parameter

adjustment. Two keys provide Cold Feed and Gas Purge

functions, and a connector receptacle is provided for an

optional dual procedure remote control.

The unit has 3 operating modes: 2-step trigger, 4-step trig-

ger and spot. Three functions can be selected: Volts or

Trim Preset/arc (memory) voltmeter, Run-in speed and weld

speed (IPM or m/min.) or (memory) ammeter. In addition,

when 4-step trigger mode is selected, crater fill WFS is also

adjustable. In addition, when 4-step trigger mode is select-

ed, crater fill WFS is also adjustable. Up to three timers are

available depending on the mode: preflow, postflow and

spot, and 5 acceleration rates are selectable, as well as 6

Burnback settings.

The K678-2 Synergic 7F control may be used with

either of the two available 4-roll wire feed units.

b) Feeds .045 - 3/32” (1.2-2.4mm) cored wire for Outershield

GMA or Innershield processes up to 5/64” (2.0 mm).

The Synergic 7FH wire feed unit has the following

wire feeding capabilities:

a) Feeds .025 - .045” (0.6-1.2mm) solid wire for

gas-metal-arc processes.

b) Feeds .045 - (1.2mm) cored wire for Outershield

GMA or Innershield processes.

Recommended power sources are The Lincoln

Electric Company Synergic type Invertec® power

sources with 42VAC auxiliary power, and a 14-pin

connector receptacle.

STANDARD FEATURES

Wire Feed Features:

Wire Drive Unit - Incorporates low voltage permanent

magnet motor and highly efficient two-reduction spur

gearbox with insulated mounting bracket for mounting

and operation in any position. The non-fluid lubricant

won’t leak.

“Quick Release” Wire Feed System - Provides a

completely tool-less means for releasing and opening

the idle roll pressure arm, precisely adjusting the idle

roll pressure and changing the incoming and outgoing

guide tubes.

Drive Rolls and Guide Tubes - Provide long life,

positive feeding and precise alignment of electrode.

Minimizes “birdnest” or mill-thru of wire if properly set.

(Ordered separately.)

Tachometer Feedback - Provides proper wire feed

acceleration and speed accuracy, independent of fluc-

tuations in line voltage and wire loading, for reliable

arc starting and weld consistency.

Run-in Speed Setting - Allows the arc striking speed

“Run-in” to be adjusted independently of the weld feed

speed for starting optimization.

Cold Feed Speed - Provides cold feed speed adjustment

independent of weld, run-in and crater speeds.

Selectable Acceleration - Provides front panel selec-

tion of 5 acceleration rates. This feature in combina-

tion with Run-in Speed provides the ability to easily

optimize starting on any process or procedure.

Solid-State Dynamic Braking - Quickly stops wire feed

motor to minimize wire overrun during weld termina-

tion. Solid-state design requires no maintenance.

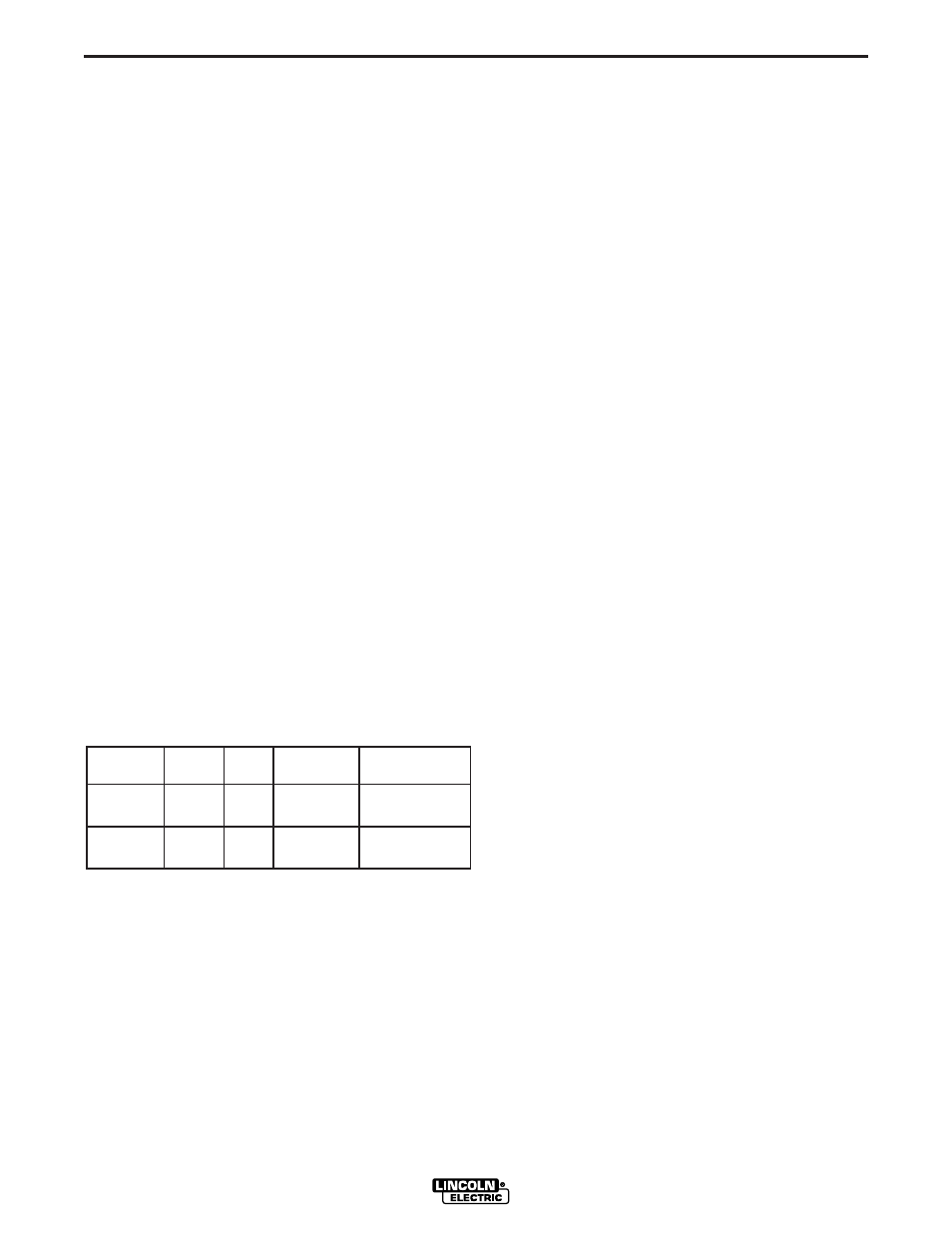

Ordering Speed Range Wire Size Range

Information Model Drive IPM (m/m) IN. (MM)

K679-1 Synergic 4-Roll 50 - 770 .025 - 3/32

7F (1.25 - 19.5) (0.6 - 2.4)

K679-2 Synergic 4-Roll 80 - 1200 .025 - .045

7FH (2.00 - 30.5) (0.6 - 1.2)

RECOMMENDED PROCESSES

AND EQUIPMENT

The Synergic 7F wire feed unit has the following wire

feeding capabilities:

a) Feeds .025 - 1/16” (0.6-1.6mm) solid wire for

gas-metal-arc processes.

The feeder to control cable assemblies are available in two types:

K680-”L” Includes a control cable with a 14-pin MS style connector on each end, and a 4/0 weld

cable. Available in lengths “L” of 16ft (4.9m) or 25ft (7.6m).

K681-”L” Same as above but does not include weld cable available in lengths “L” of 12ft (3.6m),

16ft (4.9m) or 25ft (7.6m).