Problems – Lincoln Electric IM539 Synergic 7F and 7FH User Manual

Page 29

–

29

–

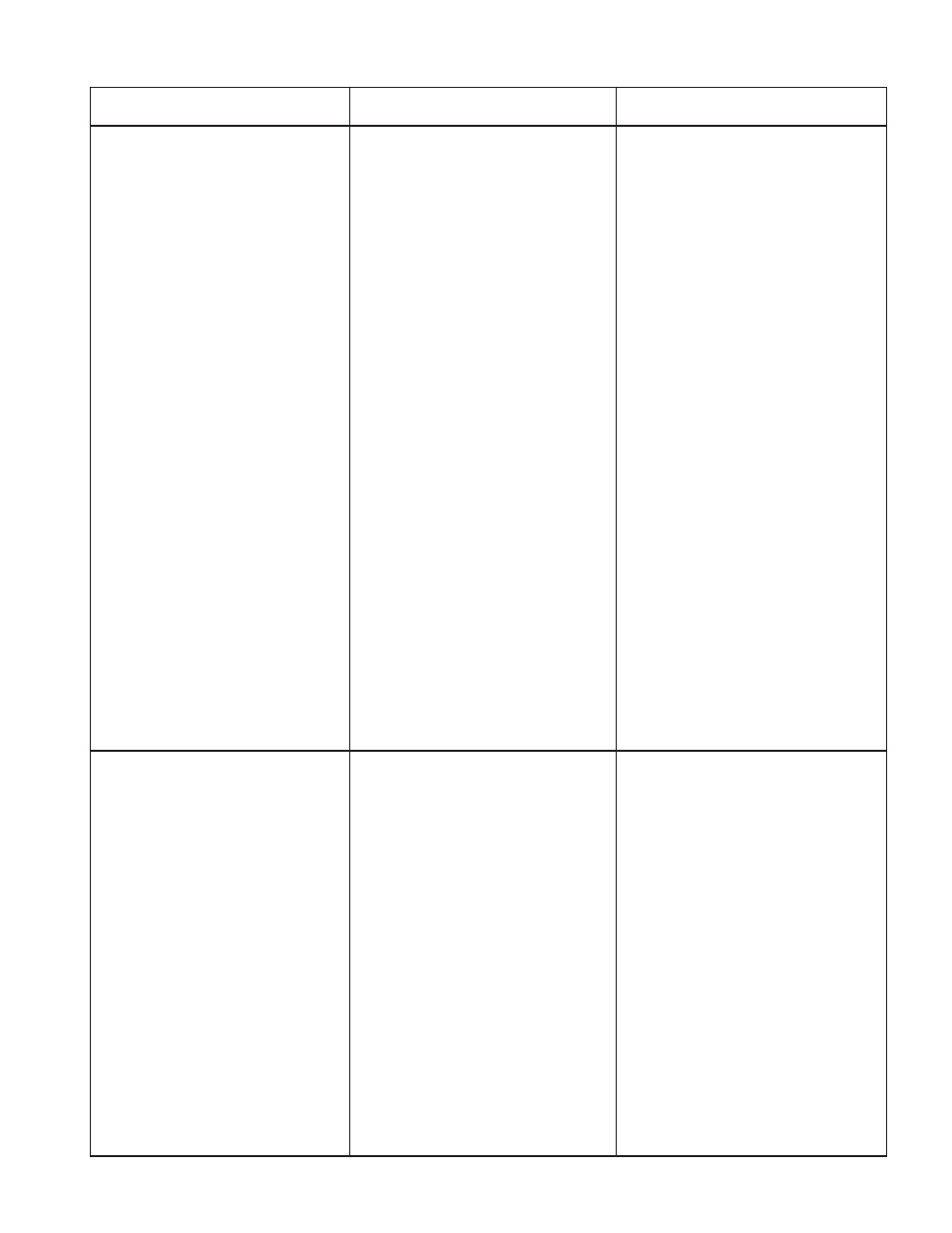

PROBLEM

1. Rough wire feeding or wire not

feeding but drive rolls turning.

2. Variable or “hunting” arc.

POSSIBLE CAUSE

a. Gun cable kinked and/or twisted.

b. Wire jammed in gun and cable.

c. Incorrect position of drive rolls

with grooves.

d. Drive rolls loose.

e. Gun cable dirty.

f. Worn drive roll.

g. Electrode rusty and/or dirty.

h. Worn nozzle or cable liner.

i. Partially flashed or melted

contact tip.

j. Incorrect idle roll pressure.

k. Improper liner, tip or guide tube.

a. Wrong size, worn and/or melted

contact tip.

b. Worn work cable or poor work

connection.

c. Loose electrode connections.

d. Wrong polarity.

e. Problem with serial

communications in control cable.

WHAT TO DO

a. Inspect gun cable and replace if

necessary.

b. Remove wire from gun and cable

feed in new wire. Note any

obstructions in gun and cable.

Replace gun and cable if

necessary.

c. See Wire Feed Drive Roll and

Guide Tubs Kits section for

proper installation of drive roll.

d. Remove, clean, install and

tighten.

e. Clean cable or replace liner.

f. Replace.

g. Replace.

h. Replace.

i. Replace contact tip.

j. Set idle roll pressure per section

on Idle Roll Pressure Setting.

k. Install proper equipment.

a. Replace tip - remove any spatter

on end of tip.

b. Inspect - Repair or replace as

necessary.

c. Be sure electrode lead is tight in

wire feeder contact block, gun

nozzle and gun tip tight.

d. Check connection at output studs

for polarity required by welding

process.

e. Make sure control cable connections are

tight. Check for consistent WFS. Make sure

parameters on Power Source display, such

as WFS, match those on wire feeder

display, if not, try changing Synergic 7F

control board. If problem persists refer to

Power Source trouble shooting information.

PROBLEMS