Operation, General description, Recommended processes and equipment – Lincoln Electric IM675 RED-D-ARC E300 User Manual

Page 11: Design features

B-1

OPERATION

RED-D-ARC E300

B-1

GENERAL DESCRIPTION

The E300 is a single phase constant current arc weld-

ing power source available in a DC output model only.

Designed for stick welding, it may also be used for

TIG welding when used with the K930-1 Tig Module.

A 15 amp 115 volt AC, Auxiliary Power duplex recep-

tacle, with circuit breaker protection is provided.

RECOMMENDED PROCESSES AND

EQUIPMENT

DC Constant Current Welding

TIG Welding

The K930-1 Tig Module can be used with this

machine to provide high frequency stabilization and a

gas valve for TIG welding. It operates on 115V 50/60

Hz power. A water valve (for water cooled TIG torch-

es) is available as an option.

DESIGN FEATURES

• Power On/Off switch.

• Continuous current control dials with exact welding

current needed for each job. Settings are precise

and free from creep.

• Spring loaded knob on the continuous current

control crank pulls out for easy adjustment and

snaps back out of the way when released.

• Recessed front panel protects controls.

• Large safety margins and protective circuits protect

rectifiers from transient voltages and high currents.

• Submersion dipping of assembled transformer and

choke in special sealing/insulating material gives

extra protection against moisture and corrosive

atmosphere.

• Outstanding Arc Stability - Transformer design pro-

vides pop-out-resistant welding.

• Reconnect panel is provided to permit changing

from one input voltage to another without reconnect-

ing transformer leads.

• Auxiliary Power-15 amps at 115 VAC

Be sure the E300 is properly installed, and that all

accessories are properly hooked up before attempting

operation.

DUTY CYCLE (WELD)

This machine is rated at a 30% duty cycle at 250

amps or 50% duty cycle at 200 amp output. Duty

cycle is based on a 10 minute period. Therefore,

the welder can be loaded at 200 amperes for 5

minutes out of each 10 minute period. Higher duty

cycles can be used at lower currents; see rating

plate information.

AUXILIARY POWER

• One 15 amp 115 VAC grounding duplex receptacle

is standard. Also provided is a receptacle cover and a

15 amp circuit breaker for Auxiliary circuit protection.

CONTROL OPERATION

• Current Control Handle

Rotating the hand wheel raises and lowers the

output current allowing the operator to dial the

desired current. Clockwise rotation reduces the

current while counter-clockwise rotation increases

the current. Turning the current control handle

also drives the output pointer at the bottom of the

nameplate which indicates the stick welding cur-

rent at NEMA arc volts.

• TIG Welding

The E300 with the optional Tig Module is an inex-

pensive equipment combination for part-time pro-

duction or repair TIG welding of aluminum, mag-

nesium, thin stainless steel and many space-age

metals. The E300 can be used for normal stick

electrode welding with the Tig Module attached.

The Tig Module includes high frequency genera-

tor, gas valve and needed controls. It operates

on 115V, 60 Hz AC power.

NOTE: Installation instructions are in the kit. (When

using the E300 with any other high frequency equip-

ment, an R.F. bypass capacitor must be installed.

Order Kit T12246.) To provide protection, the welder

grounding stud or frame must be connected to ground

(see instructions on grounding in Machine Installation

section). Also follow the grounding instructions given

in the Tig Module Instruction manual.

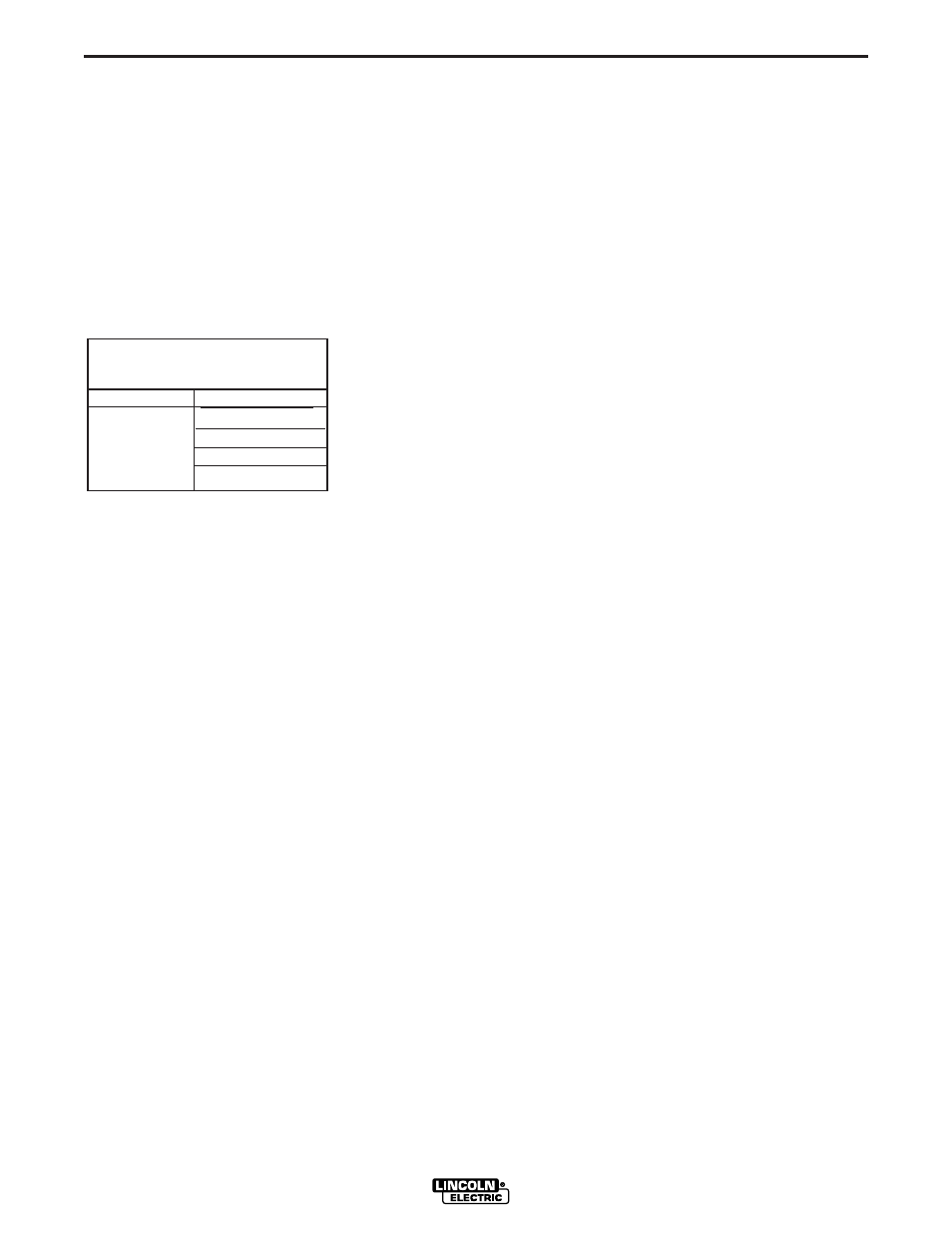

DC

40-250 Amps

DUTY CYCLE OUTPUT AMPS

100% 140 Amps

50% 200 Amps

30% 250 Amps

20% 300 Amps