Operation, Controls and settings – Lincoln Electric IM606 RANGER 275 User Manual

Page 19

B-3

OPERATION

B-3

RANGER 275

CONTROLS AND SETTINGS

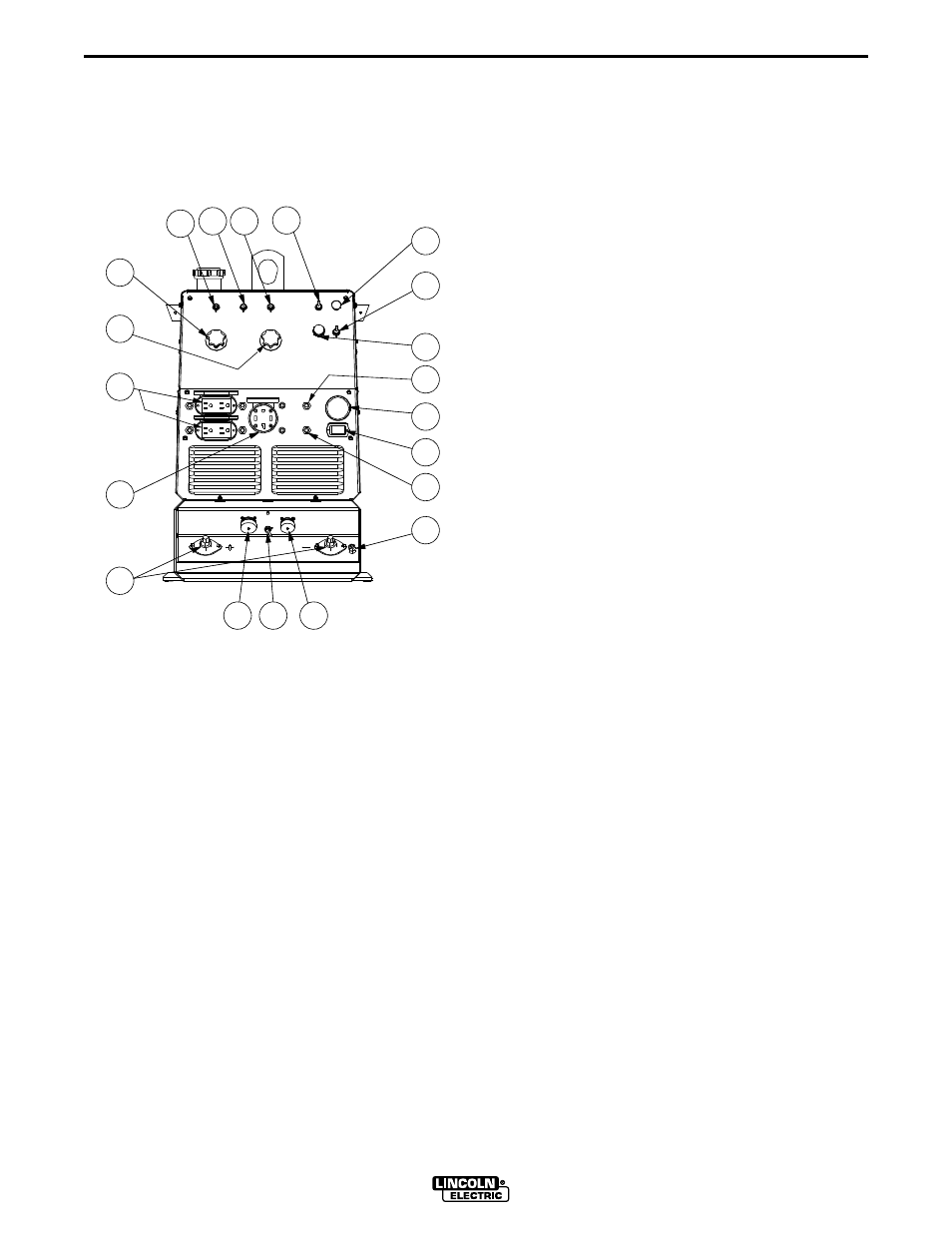

All generator/welder controls are located on the

Output Control Panel of the machine case front. Idler

control, and start/stop controls are also on the case

front. See Figure B.1 and the explanations that follow.

FIGURE B.1

OUTPUT PANEL CONTROLS

WELDER/GENERATOR CONTROLS

See Figure B.1 for the location of the following features:

1. OUTPUT CONTROL: Allows full range adjustment of

welding current or voltage.

2. ARC CONTROL: The “ARC CONTROL” is active in

two modes: “STICK/TIG” and “WIRE WELDING” with

different purposes in each mode.

3. MODE SWITCH: Selects three possible modes of

welding operation, 1.) CC Stick/TIG Welding, 2.) Pipe

Welding, and 3.) CV Wire Welding.

4. LOCAL/REMOTE CONTROL SWITCH: Allows the

operator to control welding output at the welding con-

trol panel or at a wire feeder, TIG amptrol, or a K857

remote control.

5. CONTACTOR SWITCH: The toggle switch labeled

“WELDING ON” and “CONTACTOR CONTROLLED”

is used to control the operation of the solid state out-

put contactor. With the switch in the “CONTACTOR

ON” position, the contactor is closed at low and high

idle.

6. BATTERY CHARGER CIRCUIT BREAKER: Opens

the engine battery circuit if a short develops. Engine

will not crank if this circuit breaker is open.

7. WIRE FEEDER POWER CIRCUIT BREAKER: Opens

the wire feeder circuit and disables the feeder if a fault

is detected in the circuit.

8. 15 AMP, 120 VOLT DUPLEX RECEPTACLES:

Connection point for supplying 120 volt power to oper-

ate one or more electrical devices.

9. 50 AMP, 120/240 VOLT RECEPTACLE: Connection

point for supplying 240 volt power to operate one

electrical device.

10. WELD OUTPUT TERMINALS WITH FLANGE NUT:

Provides the connection point for the electrode and

work cables.

11. GROUND STUD: Provides a connection point for

connecting the machine case to earth ground for the

safest grounding procedure.

12. 6 PIN AMPHENOL: For attaching optional remote

control equipment to the Ranger 275.

13. 14 PIN AMPHENOL: For attaching wire feeder con-

trol cables to the Ranger 275 (Includes contactor clo-

sure circuit, remote control circuit, wire feeder 115/42

volt power source).

14. WIRE FEEDER VOLTMETER POLARITY SWITCH:

matches polarity of wire feeder voltmeter to polarity

of electrode.

15. ENGINE RUN-STOP SWITCH: Energizes engine cir-

cuit.

16. ENGINE START PUSHBUTTON SWITCH:

Energizes starter solenoid contactor and fuel sole-

noid.

17. ENGINE CHOKE

18. AUTO IDLER SWITCH: In the “AUTO” mode, the

engine goes to low idle speed 12 seconds after a

welding or auxiliary power load is removed. Engine

goes to high speed when the load is re-applied.

19. BATTERY CHARGER AMMETER

20. ENGINE HOUR METER

5

4

3

1 5

1 7

1 8

1 6

1 9

2 0

1 1

1 2

1 4

1 3

1 0

6

7

9

8

1

2