Electrical input connection, Warning, Electrical installation for pro-cut 40 – Lincoln Electric IM422 PRO-CUT 40 User Manual

Page 9: Capacitor discharge procedure, Input voltage setup power cord connection

ELECTRICAL INPUT CONNECTION

Electrical Installation for PRO-CUT 40

a. The PRO-CUT 40 should be connected only by a qualified

electrician. Installation should be made in accordance with

the U.S. National Electrical Code, all local codes and the

information detailed below.

b. When received directly from the factory, the dual voltage

(208-230) machines are internally connected for the highest

voltage (230) input. If 230 is the desired input, then the

machine may be connected to the power system without

any setup required inside the machine.

c. 208 volt operation requires a voltage panel setup: Remove

roof, discharge input capacitors, and move lead “A” from

“230” to “208” of terminal strip “1”. See following instruc-

tions.

NOTE: Do not power the PRO-CUT 40 off of the auxiliary power

supply of an engine driven welder. If the voltage peaks

from the engine welder exceed 380V the filter capaci-

tors, FETS of other circuity may fail on the PRO-CUT 40.

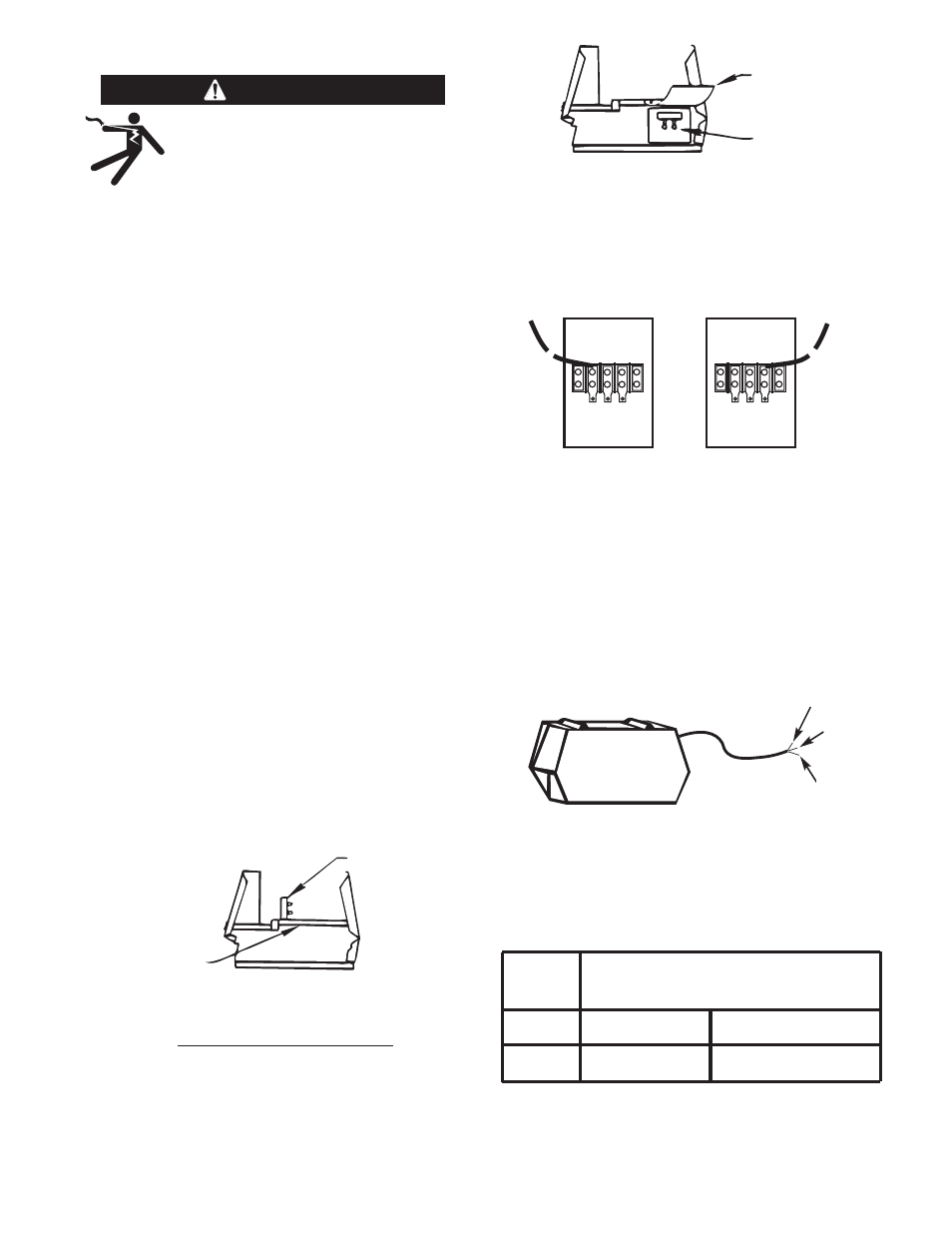

Capacitor Discharge Procedure

a. Locate discharge resistor (25 ohms 25W)

attached to fan baffle. Resistor has no leads

connected to it.

b. Remove resistor from fan baffle.

c. Hold resistor body with electrically insulated

glove. DO NOT TOUCH TERMINALS.

Carefully lift mylar insulation. Connect resistor

terminals across two hex head cap screws in

position shown. Hold in position for 1 second.

Repeat for capacitor located on opposite side.

d. Use a DC voltmeter to check that voltage is not

present across terminals.

e. Replace discharge resistor onto fan baffle.

Input Voltage Setup

Power Cord Connection

A 10-foot power cord is provided and wired into the

machine. Follow the power cord connection instruc-

tions. Incorrect connection may result in equipment

damage.

Install in accordance with all local and national electric

codes.

RECOMMENDED FUSE SIZES

BASED ON THE U.S. NATIONAL ELECTRICAL CODE

AND MAXIMUM MACHINE OUTPUTS

INPUT VOLTS*

FUSE SIZE IN AMPS

(TIME DELAY FUSES)

1 Phase

208

60

60 Hz / 50 Hz

230

60

* Input voltage must not exceed ± 10% of rated value.

– 9 –

ELECTRIC SHOCK can kill.

• Disconnect input power before

proceeding.

• Have a qualified electrician make

the input connections.

• Be sure to discharge capacitors with the

procedure outlined below before working in

that area of equipment.

------------------------------------------------------------

WARNING

RESISTOR

FAN BAFFLE

LIFT MYLAR

INSULATION

CAPACITOR

TERMINALS

208

230

H1

H3

TERMINAL STRIP 1

208V INPUT

208

230

H1

H3

TERMINAL STRIP 1

230V INPUT

A

A

BLACK

GREEN

WHITE