Troubleshooting, Caution – Lincoln Electric IM987 POWERBrazer User Manual

Page 17

POWERBrazer

E-2

E-2

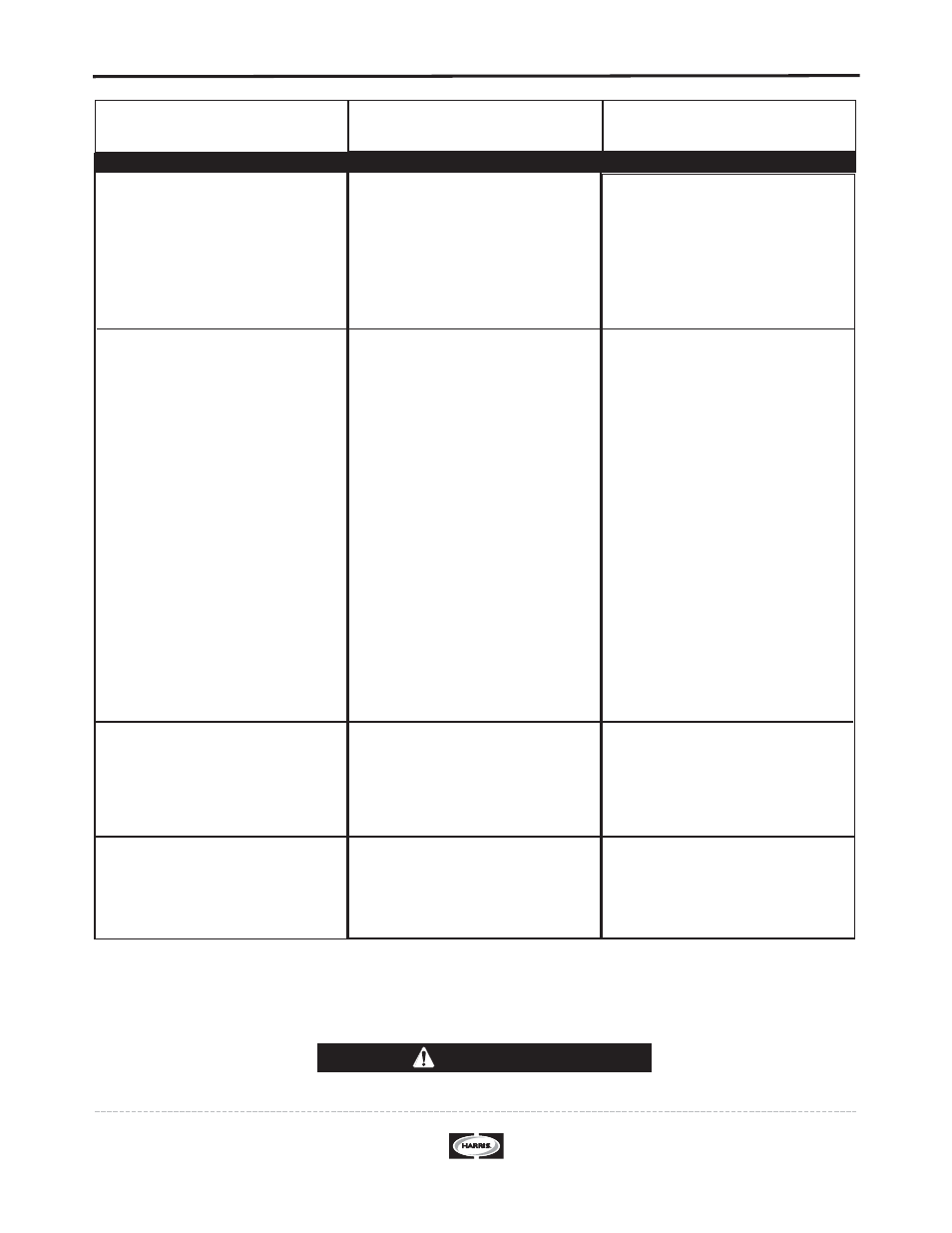

TROUBLESHOOTING

Observe all Safety Guidelines detailed throughout this manual

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

The feeder does not power up: no

cold feed.

Inconsistent wire feeding or wire not

feeding but drive rolls turning.

The wire feed speed is fast (maxi-

mum) and there is no change when

the wire feed speed knob is adjust-

ed.

The POWERBrazer stops feeding

after a few seconds. After a while, it

will begin to feed again when it has

been retriggered.

1. The PowerBrazer is unplugged.

2. The power switch is turned off.

3. The circuit breaker tripped.

4. The motor is not receiving power.

1. The gun cable is kinked and/or

twisted.

2. The wire is jammed in the gun and

cable.

3. The gun liner is dirty or worn.

4. The filler wire is corroded or dirty.

5. Improper gun liner, tip, drive rolls

and/or inner wire guide.

6. Incorrect tension arm pressure on

the drive rolls.

7. The spindle brake is too tight.

8. Worn drive roll.

1. The tachometer is connected

improperly.

2. The tachometer has failed.

1. The motor has gone into thermal

overload.

1. Plug in the PowerBrazer.

2. Turn on the power switch.

3. Check cords for damage. Verify

the brazing wire easily feeds

through the gun. Consult a trained

repair person if the circuit breaker

repeatedly trips.

4. Consult a trained repair person.

1. Keep the gun cable as straight as

possible. Avoid sharp corners or

bends in the cable.

2. Remove the gun from the wire

feeder and pull the jammed wire

out of the gun and cable.

3. Blow dirt out of the liner with low

pressure (40psi or less). Replace

the liner if worn.

4. Use only clean electrode. Use

quality electrode from the Harris

Products Group.

5. Verify the proper parts are

installed.

6. Most filler wires feed well with the

pressure arm set between “2” and

“4”.

7. Verify the spool of wire moves

with minimal effort.

8. Replace the drive rolls if worn or

filled with dirt.

1. Verify all of the tachometer leads

are properly connected.

2. Replace the motor and tachome-

ter assembly.

1. Verify that the filler wire can be

easily pulled through the gun

when the pressure arm is open.

Output Problems

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION