Installation, Attachment and arrangement of "pig-tails, A-4 remote output control options – Lincoln Electric IM664 Multi-Weld 350 Arc Converter User Manual

Page 11: Cv mode wire welding, Cc mode stick welding and gouging, Quick-connect "pig-tails

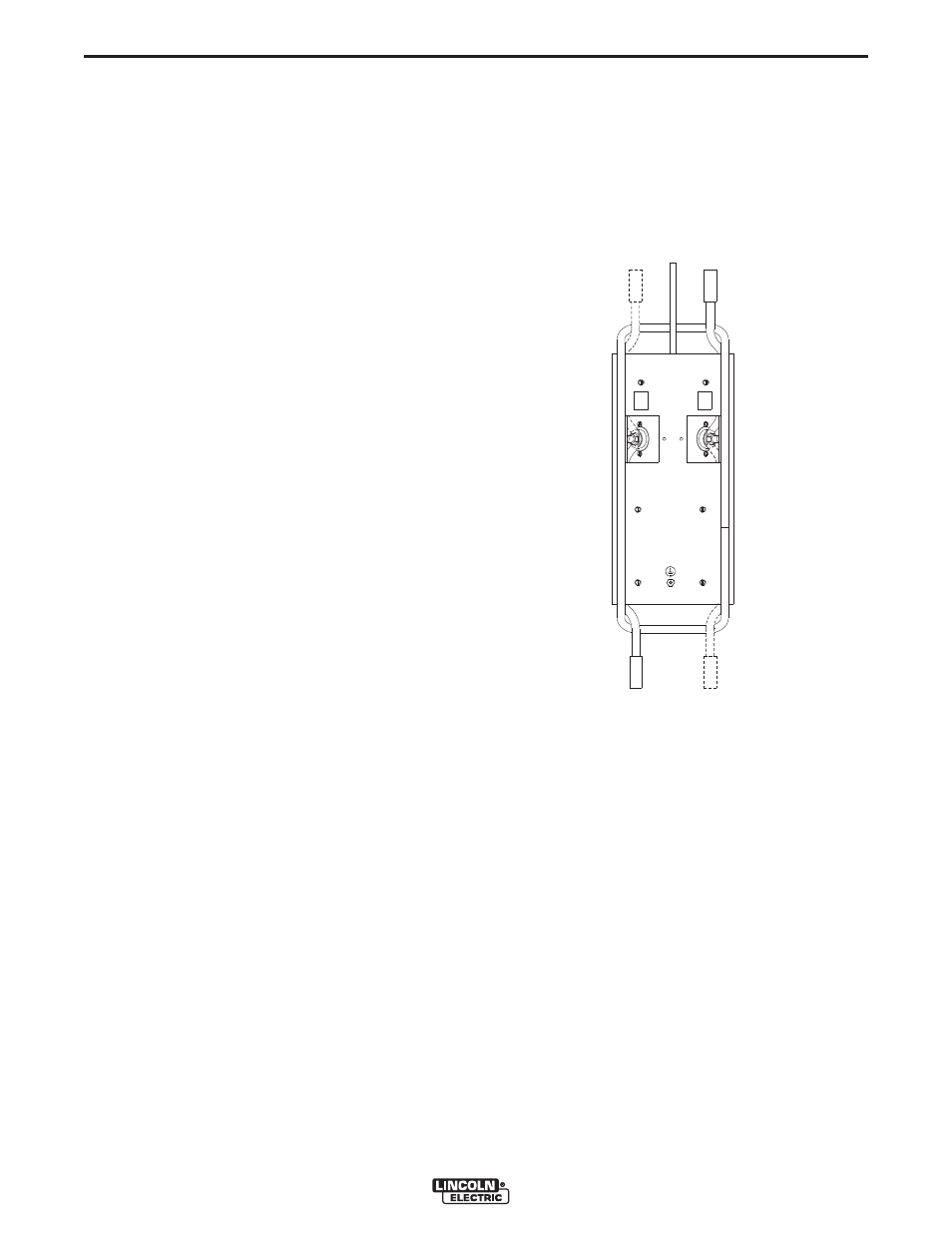

ATTACHMENT AND ARRANGEMENT OF

"PIG-TAILS"

To best suit the desired inter-connection of the

Converters the "pig-tail" cables may be routed into the

front cable channels, and/or into the back for single or

double "pig-tail" cables to the bottom-accessed cov-

ered cable connection studs. (See below and refer to

Figures 1 and 2.):

To connect the "pig-tail" cables to the Converter:

1. Stand the Converter vertically on its rear handle

and skid to gain access to the bottom stud

covers, then remove the two 0.25"(6.3mm)

screws securing each cover and fold out the

cover insulation.

2. Route the appropriate "pig-tail" cable lug ends

under the skid rail (for strain-relief) through the

desired front and/or rear corner channels to the

exposed 0.5"(13mm) stud, and remove the flange

nut with a .75"(19mm) wrench. Note: Input supply

cable(s) must connect through "INPUT +" labeled

channels, and output weld cable(s) must connect

through "ELECTRODE +" labeled channels.

3. Slip the "pig-tail" cable lug(s) over the stud and

re-secure the flange nut, making sure that lug(s)

nowhere touch any sheet metal of the stud hous-

ing, then fold back the cover insulation and

replace the stud cover.

BOTTOM VIEW

TO ELECT.

TO ELECT.

TO

WORK

TO POWER

SOURCE

TO POWER

SOURCE

+

INPUT

+

ELECTRODE

ELECT.

+

ELECT.

+

+

IN

+

IN

A-4

INSTALLATION

MULTI-WELD 350

A-4

REMOTE OUTPUT CONTROL OPTIONS

The Multi-Weld 350 is provided with a 6-pin remote

receptacle to permit use with the 25ft.(7.6 m) K857 or

100ft.(30.4 m) K857-1 Remote Output Control options,

or with the LN-25 equipped with the K444-1 Remote

Control option. These Remotes have single-turn reso-

lution on a Min to Max numbered dialplate.

CV MODE WIRE WELDING

The Converter in CV mode was designed for use with

an arc-powered wire feeder like the LN-25. The

Converter output is always "hot" when the mode

switch is not OFF, so it is recommended that the LN-

25 model be equipped with the internal contactor in

order to have a "cold" electrode when the gun trigger

is released.

The CV mode recommended processes are positive

(+) polarity wire welding within the output capacity of

the Converter, including:

CC MODE STICK WELDING

AND GOUGING

The CC mode recommended processes are positive

(+) polarity stick and arc gouging within the output

capacity of single, or paralleled, Converters; including:

QUICK-CONNECT "PIG-TAILS"

The Multi-Weld 350 is factory provided with two 21

in.(53 cm) long 2/0 AWG (70mm2 ) "pig-tail" cables

with their 0.5"(13mm) hole lug ends routed through

the "INPUT + "(on back) and "ELECTRODE + "(on

front) cable channels of the Converter and attached to

the bottom-accessed covered cable connection studs.

Attach the preferred standard user-provided Quick-

connect terminal (such as Lincoln Twist-Mate or

Tweco 2-MPC type) to the cut-off end of these cables.

Use the female connector on the "ELECTRODE +"

cable and the male connector on the "INPUT +" cable.